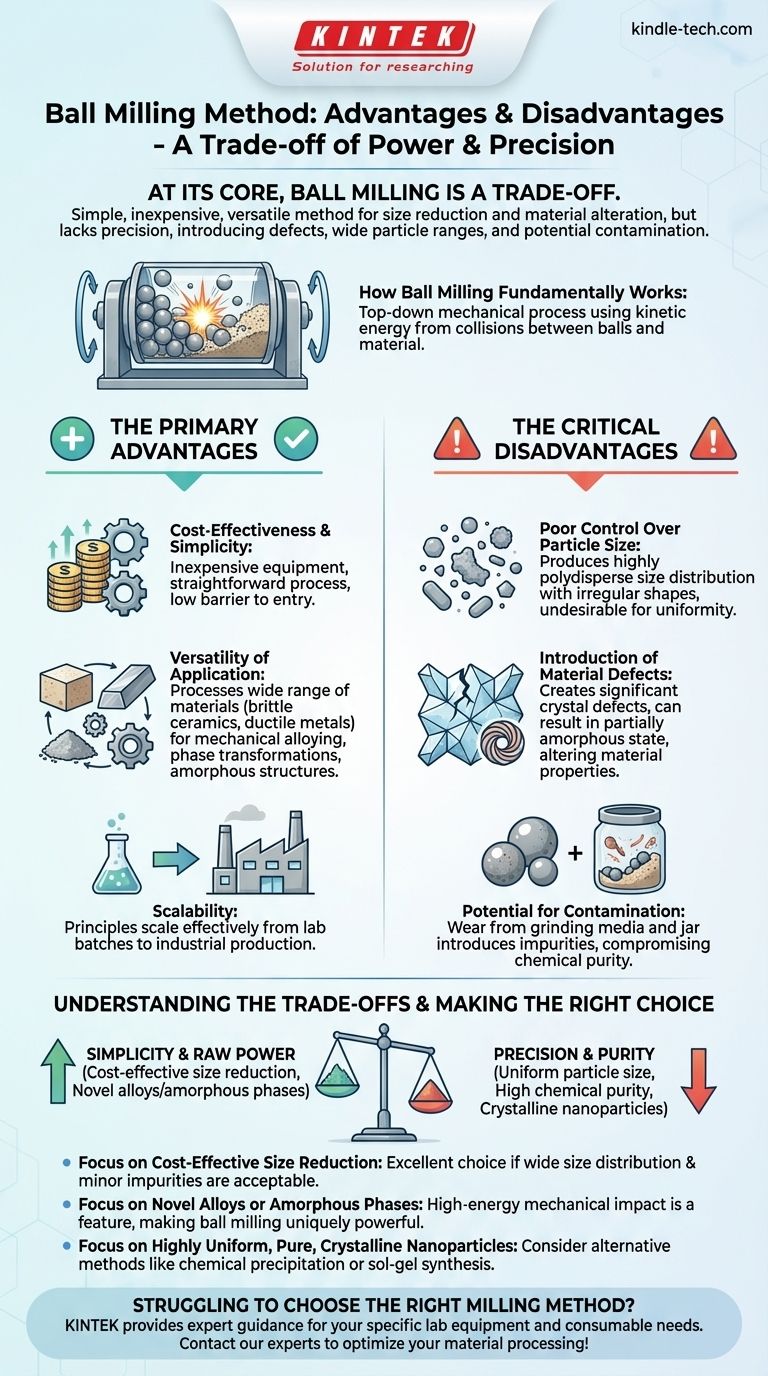

At its core, ball milling is a trade-off. It is a remarkably simple, inexpensive, and versatile method for reducing particle size and altering material properties through mechanical force. However, this "brute force" approach comes at the cost of precision, often introducing material defects, a wide range of particle sizes, and potential contamination.

Ball milling's greatest strength is its accessibility for mechanically processing materials, but this same mechanical nature is also its greatest weakness, limiting control over the final product's uniformity and purity.

How Ball Milling Fundamentally Works

Ball milling is a "top-down" mechanical process. It doesn't rely on chemistry; instead, all changes to the material are produced by the direct transfer of kinetic energy.

The Principle of Mechanical Energy

The process involves placing a material powder into a jar with hardened balls (the grinding media). The jar is then rotated at high speed, causing the balls to cascade and collide with the material.

These repeated high-energy collisions are the engine of change, leading to a cycle of particle fracturing, cold-welding, and re-fracturing.

The Primary Advantages

The benefits of ball milling are rooted in its simplicity and raw power, making it a staple in many labs and industries.

Cost-Effectiveness and Simplicity

The equipment is relatively inexpensive and the process is straightforward to perform. This low barrier to entry makes it an accessible technique for a wide range of applications.

Versatility of Application

Ball milling is not just for grinding. It can be used on a vast array of materials—from brittle ceramics to ductile metals—to achieve goals like mechanical alloying, phase transformations, and creating amorphous structures.

Scalability

The principles of ball milling scale effectively from small laboratory-scale batches to large industrial production, making it a viable manufacturing process.

The Critical Disadvantages

The uncontrolled, high-energy nature of the process introduces several significant drawbacks that must be carefully considered.

Poor Control Over Particle Size

The process naturally produces particles with a wide range of sizes and irregular shapes. This is known as a highly polydisperse size distribution, which is undesirable for applications requiring uniformity.

Introduction of Material Defects

The intense mechanical impacts create significant crystal defects within the material's structure. This can alter the material's properties and may even result in a partially amorphous (non-crystalline) state.

Potential for Contamination

The constant collision and grinding can cause wear on both the milling balls and the jar itself. This wear debris can introduce impurities into your powder, compromising its chemical purity.

Low Final Surface Area

While the process breaks particles down, the intense pressure can also fuse them together through cold-welding. This agglomeration can result in a final powder with a surprisingly low surface area compared to materials produced by other methods like chemical synthesis.

Understanding the Trade-offs

Choosing ball milling requires you to weigh its efficiency against its lack of finesse. The key is to understand whether its inherent side effects are a problem or a feature for your specific goal.

Simplicity vs. Precision

Ball milling offers simplicity and speed. However, if your application demands precise control over particle size, shape, and crystallinity, alternative methods like chemical precipitation or sol-gel synthesis are superior.

Defects: A Feature or a Flaw?

The generation of crystal defects is often seen as a disadvantage. However, for certain applications like creating unique alloys or enhancing catalytic activity, these defects are the desired outcome. The mechanical energy makes these novel material states possible.

Process Intensity vs. Purity

Achieving smaller particle sizes requires longer milling times and higher energy. This directly increases the risk of contamination from the grinding media and can generate excess heat, potentially causing unwanted changes in the material.

Making the Right Choice for Your Goal

Your end goal determines whether ball milling is the appropriate tool for the job.

- If your primary focus is cost-effective particle size reduction: Ball milling is an excellent choice, provided you can tolerate a wide particle size distribution and potential minor impurities.

- If your primary focus is creating novel alloys or amorphous phases: The high-energy mechanical impact is not a bug, but a feature, making ball milling a uniquely powerful and suitable method.

- If your primary focus is producing highly uniform, pure, crystalline nanoparticles: You should strongly consider alternative methods, as ball milling's lack of precise control and risk of contamination are significant liabilities.

Ultimately, ball milling is a powerful tool when its mechanical nature is deliberately leveraged to achieve the desired material outcome.

Summary Table:

| Aspect | Advantage | Disadvantage |

|---|---|---|

| Cost & Simplicity | Inexpensive equipment, easy to use | Lack of precision compared to other methods |

| Versatility | Can process a wide range of materials (ceramics, metals) | Naturally produces a wide range of particle sizes (polydisperse) |

| Material Effects | Can create novel alloys and amorphous phases (mechanical alloying) | Introduces crystal defects and can cause contamination from wear |

| Scalability | Principles scale effectively from lab to industrial production | Intense process can lead to agglomeration and low surface area |

Struggling to choose the right milling method for your materials? KINTEK specializes in lab equipment and consumables, providing expert guidance to help you select the perfect solution for your specific needs—whether you require the raw power of ball milling or a more precise alternative. Contact our experts today to optimize your material processing and achieve your desired results!

Visual Guide

Related Products

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- How does a planetary mill work? Harnessing High-Energy Impact for Nano-Grinding

- What are the disadvantages of planetary ball mill? Key Drawbacks in Energy, Noise, and Wear

- What is the function of a planetary ball mill for c-LLZO precursors? Master Solid Electrolyte Prep

- What is the principle of planetary ball mill? Achieve Rapid, High-Energy Grinding for Your Materials

- What is the difference between a ball mill and a planetary mill? Choose the Right Grinding Tool for Your Lab