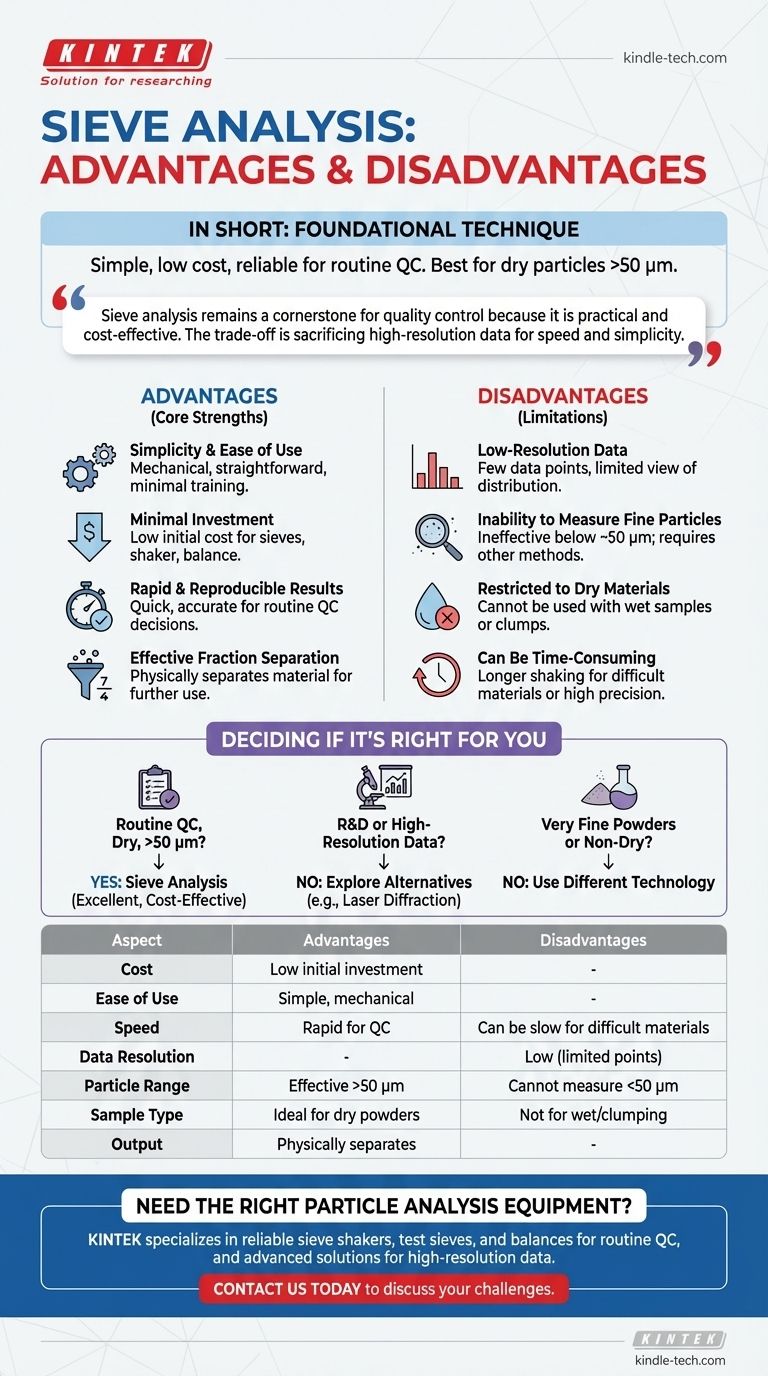

In short, sieve analysis is a foundational technique valued for its simplicity, low cost, and reliable results, making it ideal for routine quality control. However, its primary disadvantages are its low resolution, its inability to measure very fine particles (below ~50 µm), and the requirement that all samples must be dry.

Sieve analysis remains a cornerstone of particle sizing for quality control because it is practical and cost-effective. The critical trade-off is sacrificing high-resolution data for operational speed and simplicity.

The Core Strengths of Sieve Analysis

Sieve analysis is one of the most traditional and widely used methods for measuring particle size distribution for a reason. Its advantages lie in its practicality and reliability for many industrial applications.

Simplicity and Ease of Use

The process is mechanical and straightforward, requiring minimal specialized training to perform accurately. It involves shaking a sample through a stack of sieves with progressively smaller mesh sizes.

Minimal Investment

Compared to more advanced particle analysis techniques like laser diffraction, the initial cost for sieves, a shaker, and a balance is very low. This makes it an accessible option for almost any operation.

Rapid and Reproducible Results

For many materials, the test provides accurate and repeatable results in a relatively short time. This speed makes it highly effective for quality control where quick decisions are necessary.

Effective Fraction Separation

The method doesn't just measure particle size; it physically separates the material into different size fractions. These separated fractions can then be used for further analysis or other purposes.

Understanding the Trade-offs and Limitations

While effective, the method has clear limitations that make it unsuitable for certain applications. Understanding these drawbacks is key to knowing when to choose an alternative.

Low-Resolution Data

A standard stack of test sieves typically has a maximum of eight sieves. This means the resulting particle size distribution curve is based on only a few data points, offering a low-resolution view of the material's characteristics.

Inability to Measure Fine Particles

The physical limitations of woven-wire mesh mean that sieve analysis is generally not effective for particles smaller than about 50 micrometers (µm). Finer powders require more advanced analytical methods.

Restricted to Dry Materials

The technique relies on the free flow of particles through the sieve mesh. It is fundamentally designed for dry, free-flowing powders and cannot be used with wet samples, slurries, or materials that clump with moisture.

Can Be Time-Consuming

While often described as fast, the process can become time-consuming if the material is difficult to sieve or if a very high degree of precision is required, demanding longer shaking times.

How to Decide if Sieve Analysis is Right for You

Choosing the correct particle analysis method depends entirely on your specific goals and the nature of your material.

- If your primary focus is routine quality control for dry materials >50 µm: Sieve analysis is an excellent, cost-effective, and reliable choice.

- If your primary focus is research and development or requires high-resolution data: You should explore alternative methods like laser diffraction that provide a more detailed particle size distribution.

- If your primary focus is analyzing very fine powders or non-dry samples: Sieve analysis is not suitable, and you must use a different technology.

Ultimately, selecting the right analytical tool is the first step toward achieving meaningful and actionable quality control data.

Summary Table:

| Aspect | Advantages | Disadvantages |

|---|---|---|

| Cost | Low initial investment | - |

| Ease of Use | Simple, mechanical process | - |

| Speed | Rapid results for QC | Can be slow for difficult materials |

| Data Resolution | - | Low (limited data points) |

| Particle Size Range | Effective for particles >50 µm | Cannot measure fine particles (<50 µm) |

| Sample Type | Ideal for dry, free-flowing powders | Not suitable for wet or clumping samples |

| Output | Physically separates fractions | - |

Need the right particle analysis equipment for your lab?

Sieve analysis is a cornerstone of quality control, but selecting the correct method is crucial for accurate results. KINTEK specializes in lab equipment and consumables, providing reliable sieve shakers, test sieves, and balances for your routine QC needs. We also offer solutions for more advanced techniques when high-resolution data is required.

Let our experts help you choose the perfect tool for your application. Contact us today to discuss your particle sizing challenges and ensure you get meaningful, actionable data.

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Three-dimensional electromagnetic sieving instrument

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Wet Three-Dimensional Vibratory Sieve Shaker Machine

People Also Ask

- What is the purpose of using a 40-mesh sieve for kaolin catalyst carriers? Optimizing Uniformity and Activity

- What are the uses of sieve in laboratory? Essential Guide to Particle Size Analysis

- What is the function of stainless steel test sieves? Ensure Accurate Particle Size Analysis

- Why is it necessary to pass mixed graphene/alumina composite powder through a 200-mesh sieve after vacuum drying? Guide

- What is sieve analysis of raw materials? Control Quality with Particle Size Data

- Why is sieve analysis important? Ensure Consistent Quality and Performance of Your Materials

- What is the tool called that is used in the process of sieving? The Essential Guide to Sieves and Particle Separation

- How does a standard test sieve contribute to the preparation of BCZYYb electrolyte powders? Enhance Particle Uniformity