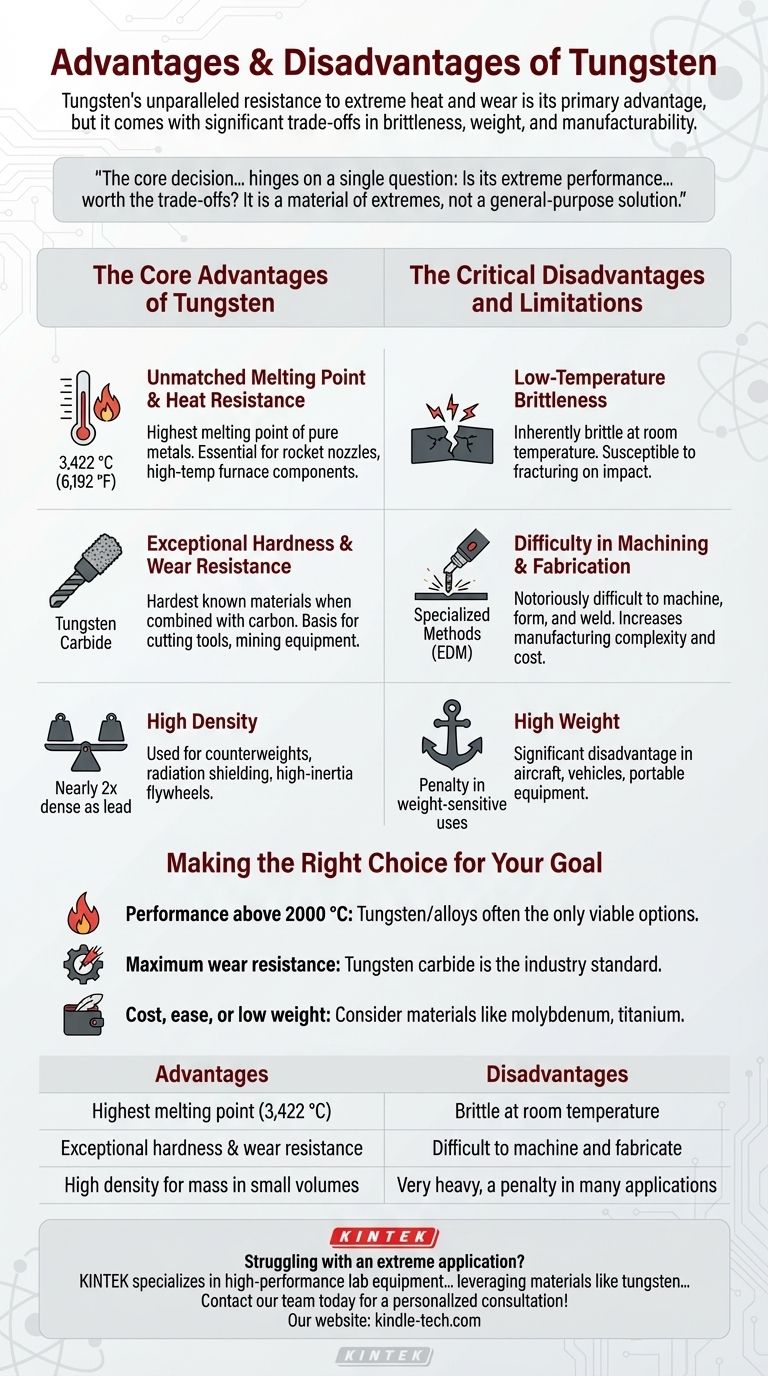

Tungsten's primary advantage is its unparalleled resistance to extreme heat and wear, stemming from the highest melting point of any pure metal. However, this same strength creates significant disadvantages, making it a brittle, heavy, and difficult material to work with for most applications.

The core decision of whether to use tungsten hinges on a single question: Is its extreme performance in high-temperature or high-wear environments worth the trade-offs in cost, weight, and manufacturability? It is a material of extremes, not a general-purpose solution.

The Core Advantages of Tungsten

Tungsten's properties make it indispensable for applications where other metals would fail instantly. Its value is derived from its ability to withstand intense physical stress.

Unmatched Melting Point and Heat Resistance

Tungsten has the highest melting point of all pure metals at 3,422 °C (6,192 °F). This gives it exceptional strength and stability at elevated temperatures.

This property is why it's essential for applications like rocket nozzles, high-temperature furnace components, and the filaments in older incandescent light bulbs. It can handle rapid heating cycles with precision.

Exceptional Hardness and Wear Resistance

As one of the hardest metals, tungsten is incredibly resistant to scratching, deformation, and abrasion. When combined with carbon to form tungsten carbide, it becomes one of the hardest known materials.

This is the basis for its use in industrial cutting tools, mining equipment, armor-piercing munitions, and other applications that demand a long service life under constant wear.

High Density

Tungsten is one of the densest metals you can access, nearly twice as dense as lead. While this can be a drawback, it is a significant advantage in specific scenarios.

It is used for high-density applications like counterweights in aerospace and motorsport, radiation shielding, and high-inertia flywheels where maximum mass is needed in a minimal space.

The Critical Disadvantages and Limitations

The same properties that make tungsten uniquely capable also create its most significant drawbacks. Understanding these trade-offs is crucial for material selection.

Low-Temperature Brittleness

Despite its strength, pure tungsten is inherently brittle at room temperature. This means it is susceptible to fracturing on impact rather than bending or deforming.

This characteristic makes it unsuitable for structural applications that require toughness and ductility, as it can shatter under sudden loads.

Difficulty in Machining and Fabrication

Tungsten's extreme hardness and high melting point make it notoriously difficult to machine, form, and weld. Standard cutting tools are ineffective, requiring specialized methods like grinding or electrical discharge machining (EDM).

This difficulty significantly increases manufacturing complexity and cost, limiting the shapes and components that can be produced economically.

High Weight

Its high density is a clear disadvantage in any application where weight is a penalty. Using tungsten in components for aircraft, vehicles, or portable equipment would impose a severe weight burden.

For this reason, lighter metals like titanium or aluminum alloys are chosen for structural purposes unless extreme heat resistance is the overriding requirement.

Making the Right Choice for Your Goal

Selecting tungsten is rarely an arbitrary choice; it is dictated by the extreme demands of the application.

- If your primary focus is performance above 2000 °C: Tungsten or its alloys are often the only viable options for components that must maintain structural integrity in extreme heat.

- If your primary focus is maximum wear resistance and cutting ability: Tungsten carbide is the industry standard for tooling, drilling, and abrasive applications where hardness is paramount.

- If your primary focus is cost, ease of manufacturing, or low weight: You should almost always consider other materials like molybdenum, titanium, or high-strength steels first.

Ultimately, tungsten's value lies in its status as a specialist material, chosen only when its unique strengths are absolutely necessary to solve a critical engineering challenge.

Summary Table:

| Advantages | Disadvantages |

|---|---|

| Highest melting point (3,422 °C) | Brittle at room temperature |

| Exceptional hardness & wear resistance | Difficult to machine and fabricate |

| High density for mass in small volumes | Very heavy, a penalty in many applications |

Struggling with an extreme application? KINTEK specializes in high-performance lab equipment and consumables, including components that leverage materials like tungsten for unparalleled durability and heat resistance. Our experts can help you determine if tungsten is the right solution for your specific laboratory needs, ensuring optimal performance and longevity. Contact our team today for a personalized consultation!

Visual Guide

Related Products

- Thermally Evaporated Tungsten Wire for High Temperature Applications

- High Purity Gold Platinum Copper Iron Metal Sheets

- Platinum Auxiliary Electrode for Laboratory Use

- High Temperature Wear-Resistant Alumina Al2O3 Plate for Engineering Advanced Fine Ceramics

- Hexagonal Boron Nitride HBN Ceramic Ring

People Also Ask

- What is a graphite heater? Achieve Superior Temperature Uniformity and Stability

- What are the symptoms of a bad thermocouple? Diagnose a Pilot Light That Won't Stay Lit

- What material is used for furnace heating? Select the Right Element for Your Process

- How do I know if my heating element is working? Test It in 3 Simple Steps with a Multimeter

- Does heat affect tungsten? Harnessing the Power of the Metal with the Highest Melting Point

- How are tubular heating elements made? A Guide to Durable & Efficient Heating

- Why are high-performance resistance heating elements required in pyrolysis? Ensure Precise Biomass Conversion

- Why are platinum and nickel-chromium wires used in TGA? Ensure High-Temperature Data Accuracy