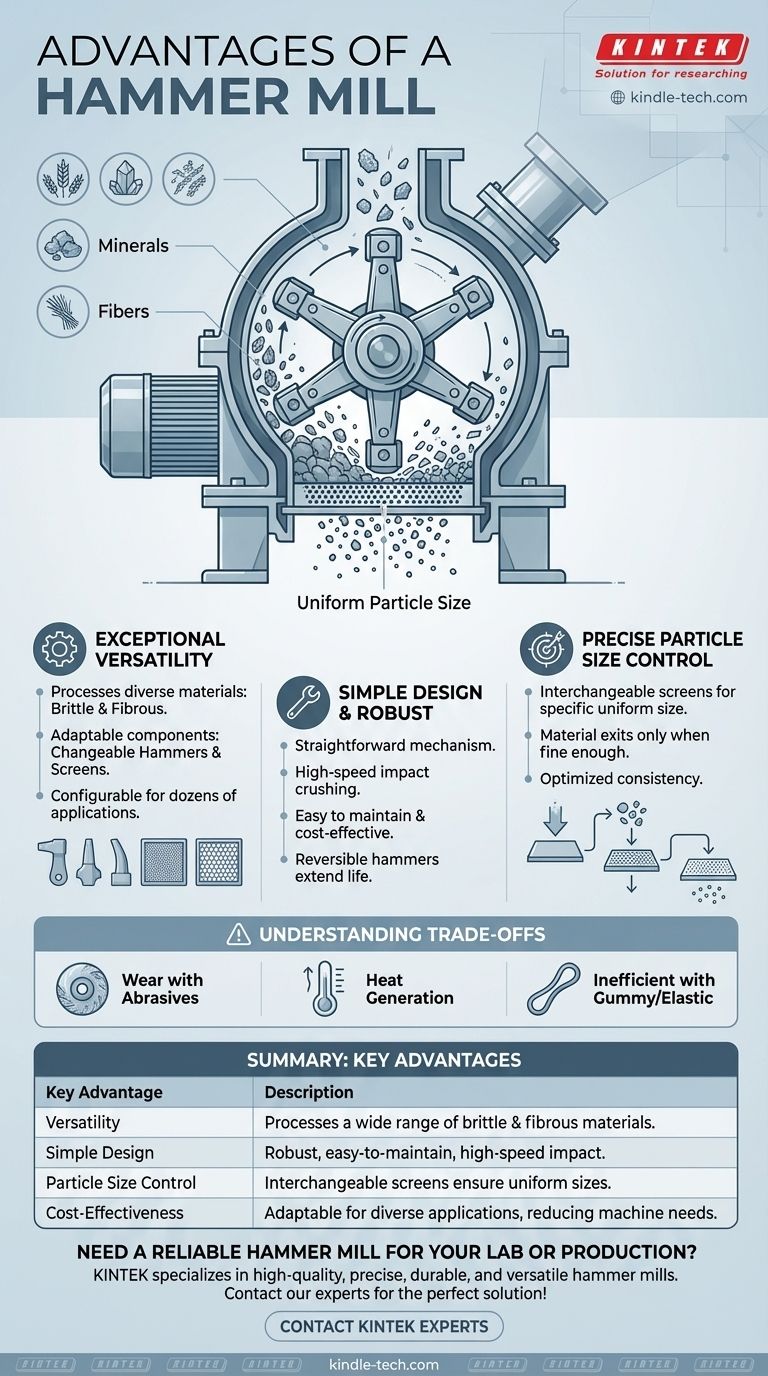

The primary advantages of a hammer mill are its exceptional versatility, simple design, and ability to produce a specific, uniform particle size. Its operational principle—high-speed impact crushing—allows it to process a wide range of brittle and fibrous materials, from grains and spices to minerals and waste products, with a high degree of control.

A hammer mill's true value lies not just in breaking materials down, but in its adaptability. By changing simple components like hammers and screens, a single machine can be configured to meet the precise output requirements for dozens of different applications.

How a Hammer Mill Achieves Its Versatility

A hammer mill's effectiveness stems from its straightforward yet highly configurable design. The core of the machine is a rotating shaft fitted with swinging hammers enclosed within a grinding chamber.

The Principle of Impact Crushing

Material enters the grinding chamber and is struck repeatedly by the hammers rotating at high velocity. The material shatters upon impact against the hammers, the chamber's wear plates, and other particles. This method is exceptionally effective for materials that are brittle, crystalline, or fibrous.

Adaptable Component Configurations

The true versatility comes from the ability to modify the internal components. Hammers come in various shapes and can often be reversed (as noted in four-way reversible designs), extending their operational life and reducing maintenance costs. This allows the mill to be optimized for shredding fibrous material or shattering brittle rock.

Precise Particle Size Control

The final particle size is determined by perforated screens or grates that form the bottom of the grinding chamber. Pulverized material cannot exit the mill until it is fine enough to pass through the screen's openings. Screens are easily interchangeable, offering precise control over the finished product's size and consistency.

Material and Construction Options

Hammer mills can be constructed from different materials, such as carbon or stainless steel. This makes them suitable for a vast range of industries, from heavy industrial applications to sanitary processes required in food and pharmaceutical production.

Understanding the Trade-offs

While highly effective, a hammer mill is not the optimal solution for every size-reduction task. Understanding its limitations is key to making an informed decision.

Wear with Abrasive Materials

While a hammer mill can process abrasive materials, doing so accelerates the wear on the hammers and internal plates. Features like replaceable wear plates mitigate this, but it results in higher maintenance frequency and consumable costs compared to other mill types designed specifically for high-abrasion applications.

Heat Generation

The high-speed impact action generates significant heat. This can be problematic for heat-sensitive materials like certain plastics or sugary products, which may melt or degrade.

Inefficiency with Gummy or Elastic Materials

Materials that are soft, gummy, or elastic do not shatter easily upon impact. Instead, they absorb the energy from the hammer blows, making the hammer mill an inefficient choice for materials like rubber.

Is a Hammer Mill Right for Your Application?

Choosing the right mill depends entirely on your material and your desired output.

- If your primary focus is producing a specific, uniform particle size from brittle or fibrous materials: The hammer mill is an excellent choice due to its screen-based size control.

- If your primary focus is processing diverse materials with a single machine: The hammer mill's configurable nature makes it one of the most versatile and cost-effective options available.

- If your primary focus is grinding abrasive, heat-sensitive, or very hard materials: You should carefully evaluate the maintenance costs and consider alternative milling technologies better suited for those specific challenges.

Ultimately, the hammer mill's simple, robust, and adaptable design has made it an indispensable tool across countless industries.

Summary Table:

| Key Advantage | Description |

|---|---|

| Versatility | Processes a wide range of brittle and fibrous materials by changing hammers and screens. |

| Simple Design | Robust, easy-to-maintain mechanism with high-speed impact crushing. |

| Particle Size Control | Interchangeable screens ensure uniform, specific output sizes. |

| Cost-Effectiveness | Adaptable for diverse applications, reducing the need for multiple machines. |

Need a reliable hammer mill for your lab or production line? KINTEK specializes in high-quality lab equipment and consumables, offering hammer mills designed for precision, durability, and versatility. Whether you're processing grains, minerals, or specialty materials, our solutions ensure efficient particle size control and reduced downtime. Contact our experts today to find the perfect hammer mill for your specific needs!

Visual Guide

Related Products

- Laboratory Single Horizontal Jar Mill

- High Energy Vibratory Laboratory Ball Mill Double Tank Type

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

People Also Ask

- What is the benefit of using tungsten carbide (WC) milling jars and balls? Achieve High-Energy Milling Efficiency

- Why are zirconia (ZrO2) milling jars recommended for sulfide electrolytes? Ensure Purity in Li6PS5Cl Synthesis

- What are the advantages of polyurethane ball mill jars for silicon nitride? Ensure Purity & Prevent Metal Contamination

- How do stainless steel grinding jars and balls contribute to mechanical alloying? Optimize HEA Powder Synthesis

- Why use zirconia ball milling jars for SiC/ZTA composite powders? Ensure High Purity & Efficient Particle Refinement