In short, the primary advantages of centrifuge filters are their exceptional speed, high sample recovery, and versatility. These devices use centrifugal force to rapidly concentrate, purify, or exchange the buffer of biological samples like proteins and nucleic acids, drastically reducing processing time compared to traditional methods like dialysis.

The core value of a centrifuge filter is its ability to trade the high-resolution separation of complex techniques like chromatography for unmatched speed and simplicity. It solves the common laboratory bottleneck of sample volume reduction and cleanup, enabling faster downstream analysis.

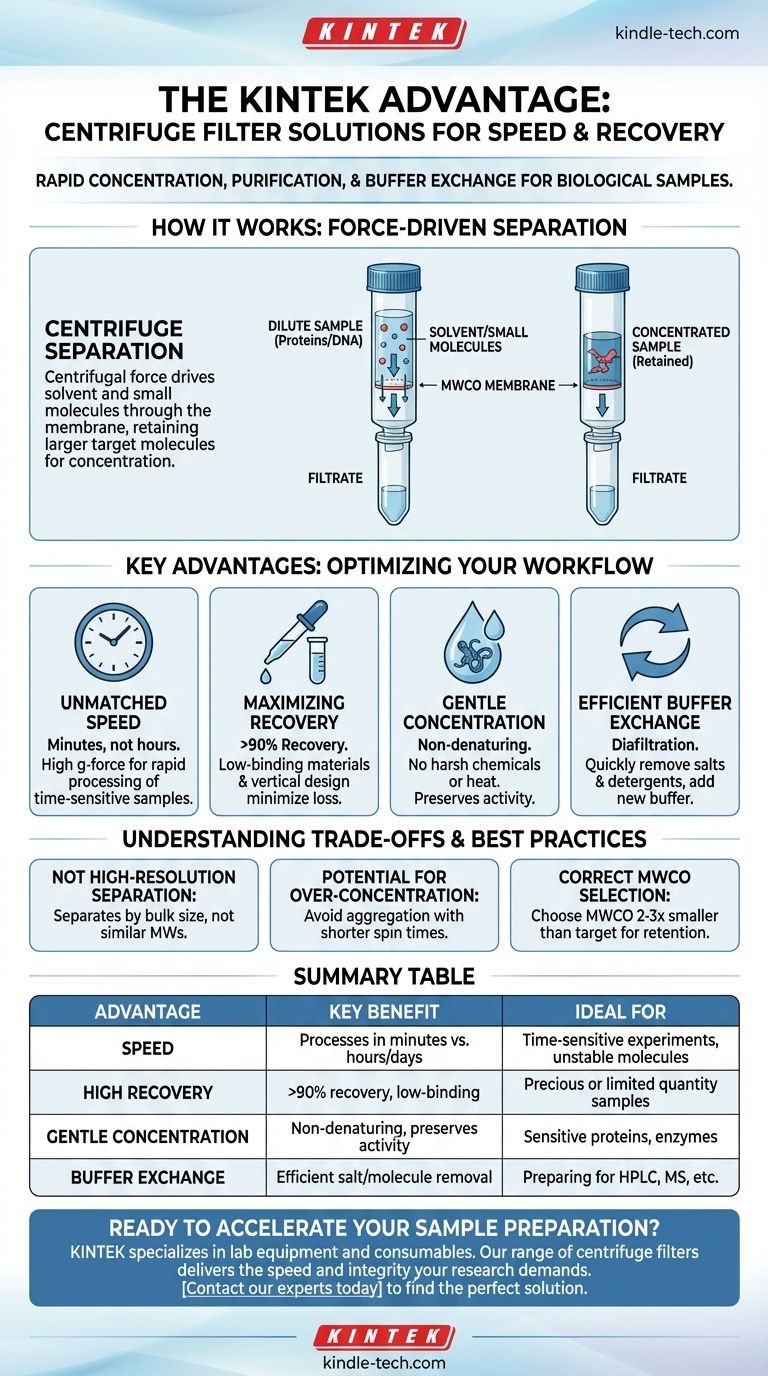

How Centrifuge Filters Work

The Core Principle: Force-Driven Separation

A centrifuge filter unit contains a membrane with a specific pore size, known as a Molecular Weight Cut-Off (MWCO). When placed in a centrifuge, the g-force drives the solvent and small solute molecules through the membrane into a collection tube.

Larger molecules, such as your protein or DNA of interest, are retained above the membrane, resulting in a smaller, more concentrated sample.

Overcoming Traditional Bottlenecks

Methods like dialysis rely on slow, passive diffusion across a membrane, often taking hours or even days to complete. Centrifuge filters actively force the separation, accomplishing the same goal in as little as 10-30 minutes.

Key Advantages in Detail

Unmatched Processing Speed

The use of high g-forces is the primary reason for the speed of centrifugal filtration. This allows you to process samples quickly, which is critical when working with unstable molecules or when needing to move rapidly to the next step of an experiment.

Maximizing Sample Recovery

Modern centrifuge filters are designed to minimize sample loss. Many feature vertical membrane designs that reduce the buildup of concentrated molecules on the filter surface—a phenomenon called concentration polarization.

Additionally, the filters are often constructed from low-binding materials, ensuring that very little of your valuable sample sticks to the device itself, leading to typical recovery rates of over 90%.

Gentle and Controlled Concentration

Unlike precipitation or evaporation, centrifugal filtration concentrates samples without harsh chemicals, pH shifts, or heat. This is a non-denaturing method that is ideal for preserving the biological activity of sensitive proteins and enzymes.

You have precise control over the final concentration by simply choosing how long to spin the sample.

Efficient Buffer Exchange (Diafiltration)

Centrifuge filters are exceptionally effective for removing salts, detergents, or other small molecules. After concentrating the sample, you simply add your new buffer, resuspend the retained molecules, and spin again. Repeating this process 1-2 times can achieve a near-complete buffer exchange.

Understanding the Trade-offs

Not a High-Resolution Technique

A centrifuge filter separates molecules in bulk based on size. It cannot distinguish between two proteins with similar molecular weights. For that level of precision, you still need to use a technique like size-exclusion or ion-exchange chromatography.

Potential for Over-Concentration

If a sample is spun for too long, the concentration of the target molecule at the membrane surface can become too high. This may lead to aggregation and precipitation, causing sample loss or reduced biological activity. It is always best to start with shorter spin times.

The Importance of Correct MWCO Selection

Choosing the wrong membrane is a common pitfall. A membrane with an MWCO that is too close to your target molecule's size will result in significant sample loss as it passes through the filter. A membrane that is too large may not retain your molecule effectively.

Making the Right Choice for Your Goal

- If your primary focus is concentrating a dilute protein sample: Choose a filter with an MWCO that is two to three times smaller than the molecular weight of your protein to ensure maximum retention.

- If your primary focus is removing salts or changing buffers: Select a filter with a low MWCO (e.g., 3 kDa or 10 kDa) to retain your protein while allowing small buffer components to pass through freely.

- If your primary focus is clarifying a raw sample before analysis: Use a centrifugal device with a larger, micron-rated filter (e.g., 0.22 µm) to remove large particulates and cells, not a MWCO-based unit.

By selecting the appropriate device, you can leverage centrifuge filters to accelerate your research and improve the quality of your results.

Summary Table:

| Advantage | Key Benefit | Ideal For |

|---|---|---|

| Speed | Processes samples in minutes vs. hours/days | Time-sensitive experiments, unstable molecules |

| High Recovery | >90% sample recovery with low-binding materials | Precious or limited quantity samples |

| Gentle Concentration | Non-denaturing, no harsh chemicals or heat | Sensitive proteins, enzymes, preserving activity |

| Buffer Exchange | Efficient removal of salts and small molecules | Preparing samples for downstream analysis (e.g., HPLC, MS) |

Ready to accelerate your sample preparation with reliable, high-recovery filtration?

KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our range of centrifuge filters is designed to deliver the speed and sample integrity your research demands. Contact our experts today to find the perfect solution for your protein or nucleic acid workflow and see how we can help you achieve faster, more reliable results.

Visual Guide

Related Products

- Custom PTFE Teflon Parts Manufacturer for Centrifuge Tubes

- Shortpass Filters for Optical Applications

- Longpass Highpass Filters for Optical Applications

- Narrow Band Pass Filters for Precision Applications

- Custom PTFE Teflon Parts Manufacturer for Sampling Filters

People Also Ask

- What technical considerations are involved in selecting quartz reaction tubes for biomass pyrolysis? Optimize Efficiency

- What is the function of corundum tubes in high-temperature refractory corrosion experiments? Ensure Data Integrity

- What are the advantages of using a centrifuge? Achieve Rapid, High-Resolution Sample Separation

- What are the benefits of using nickel-based alloys for reaction tubes? Ensure Purity in Supercritical Esterification

- How does a corundum tube function in a vacuum vertical tube furnace? Key Roles in Vapor Transport and Heat Resistance