At its core, a twin-screw extruder offers vastly superior mixing, greater processing flexibility, and higher operational efficiency compared to its single-screw counterpart. These advantages stem directly from its design, which uses two intermeshing screws to convey and process materials with a level of control that is simply unattainable with a single screw.

The fundamental advantage of a twin-screw extruder is its ability to decouple the functions of material conveying and material processing. This separation gives operators precise control over shear, temperature, and residence time, making it the superior choice for complex materials and high-value compounding applications.

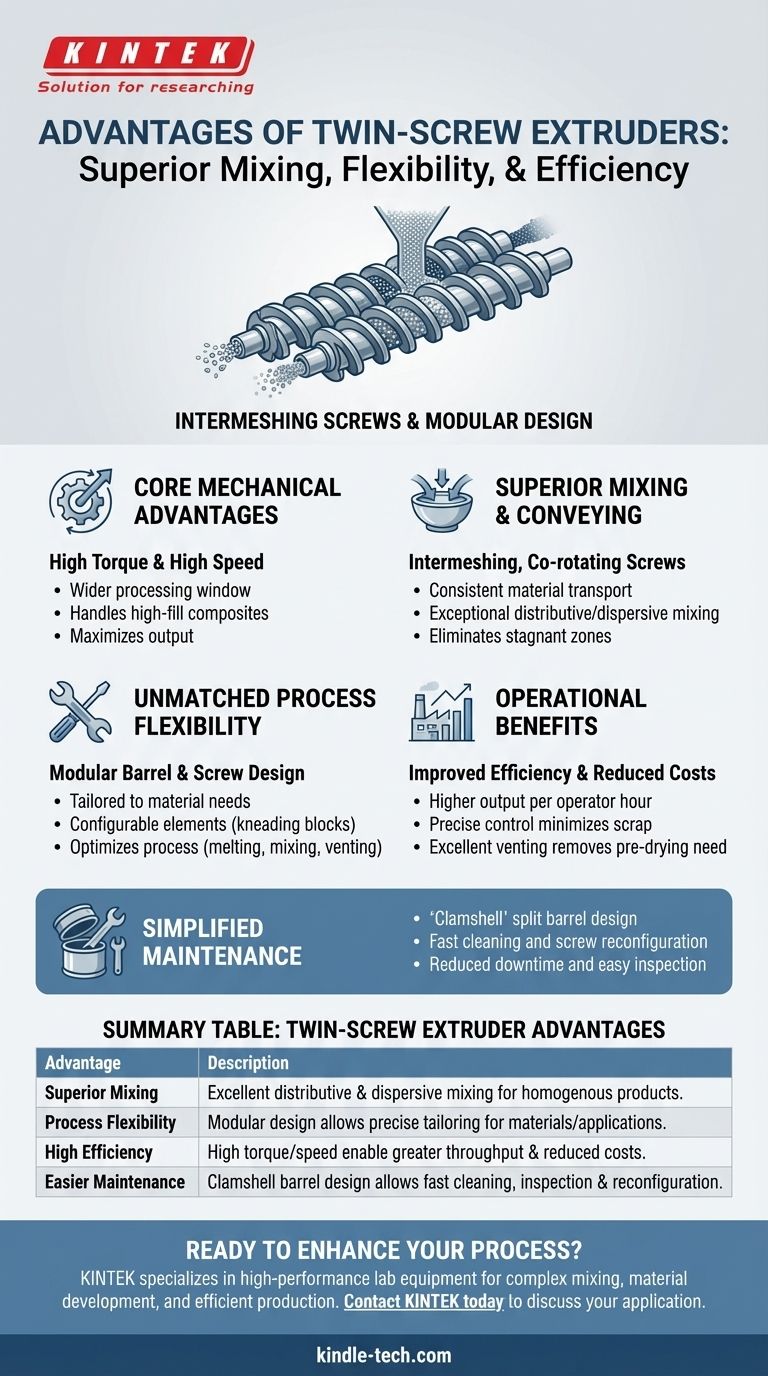

The Core Mechanical Advantages

The unique design of a twin-screw extruder creates a set of inherent mechanical benefits. These features are the foundation for its superior performance in demanding applications.

High Torque and High Speed

Twin-screw extruders are engineered for high-performance operations. Their robust gearboxes can deliver both high torque at low speeds for tough materials and high speed for maximizing output.

This capability allows for a much wider processing window than single-screw systems. It enables the machine to handle everything from highly filled composites to shear-sensitive biopolymers.

Superior Mixing and Conveying

The intermeshing, co-rotating screws are the most significant feature. They act as a positive displacement pump, ensuring consistent material transport that is less dependent on friction than a single-screw design.

This self-wiping action of the screws also provides exceptional distributive and dispersive mixing. It eliminates stagnant zones, ensuring a highly homogenous final product, which is critical for masterbatches, alloys, and composites.

Unmatched Process Flexibility

Twin-screw extruders feature a modular barrel and screw design. The screws are assembled from individual "elements" (like kneading blocks and conveying elements) on a splined shaft.

This modularity allows the process to be tailored precisely to the material. You can change the screw configuration to optimize melting, mixing, venting, and pressure building for any specific application, a level of customization impossible in single-screw machines.

Translating Mechanics to Operational Benefits

These mechanical advantages translate directly into tangible benefits in a production environment, impacting efficiency, cost, and maintenance.

Improved Labor Efficiency

The high throughput and automated control systems of modern twin-screw extruders mean that more product can be manufactured per operator hour.

Their stable and predictable performance reduces the need for constant supervision and adjustments, freeing up personnel for other critical tasks.

Reduced Long-Term Production Costs

While the initial investment is higher, twin-screw extruders often lead to lower overall costs. Their efficiency results in higher output per hour, and precise control minimizes scrap and wasted raw material.

Furthermore, their excellent venting capabilities can often eliminate the need for a separate, energy-intensive pre-drying step for certain polymers.

Simplified Maintenance and Inspection

Many twin-screw extruders are designed with a "clamshell" or split barrel. This allows the barrel to be opened horizontally, providing direct, easy access to the screws and barrel liners.

This feature makes cleaning, screw reconfiguration, and inspection for wear incredibly fast and straightforward. It drastically reduces downtime between production runs and simplifies preventative maintenance.

Understanding the Trade-offs

No technology is universally superior without context. Objectivity requires acknowledging the challenges associated with twin-screw extruders.

Higher Initial Investment

The primary drawback is cost. The complexity of the dual screws, segmented barrel, and powerful gearbox makes a twin-screw extruder significantly more expensive to purchase than a single-screw machine of comparable size.

Increased Operational Complexity

The versatility and control of a twin-screw extruder come with a steeper learning curve. Operating and configuring the machine effectively requires more training and a deeper understanding of polymer processing principles.

Making the Right Choice for Your Application

Selecting the right extruder depends entirely on your production goals and the materials you intend to process.

- If your primary focus is complex compounding or mixing: The twin-screw extruder is the definitive choice for creating polymer alloys, masterbatches, or reactive extrusion.

- If your primary focus is high-volume, simple profile extrusion: A single-screw extruder is often the more cost-effective solution for applications like pipe, sheet, or film using a single, uniform raw material.

- If your primary focus is process flexibility and R&D: The modular design of the twin-screw provides unmatched versatility for developing new formulations and running a wide variety of materials on a single machine.

Ultimately, choosing a twin-screw extruder is an investment in control, versatility, and long-term operational efficiency.

Summary Table:

| Advantage | Description |

|---|---|

| Superior Mixing | Intermeshing screws provide excellent distributive and dispersive mixing for homogenous products. |

| Process Flexibility | Modular screw/barrel design allows precise tailoring for different materials and applications. |

| High Efficiency | High torque/speed capabilities enable greater throughput and reduced production costs. |

| Easier Maintenance | Clamshell barrel design allows for fast cleaning, inspection, and screw reconfiguration. |

Ready to enhance your compounding, R&D, or production process with the superior control and efficiency of a twin-screw extruder?

KINTEK specializes in high-performance lab equipment and consumables, serving the precise needs of laboratories and R&D facilities. Our expertise ensures you get the right solution for complex mixing, material development, and efficient production.

Contact KINTEK today to discuss how a twin-screw extruder can benefit your specific application and unlock new levels of performance.

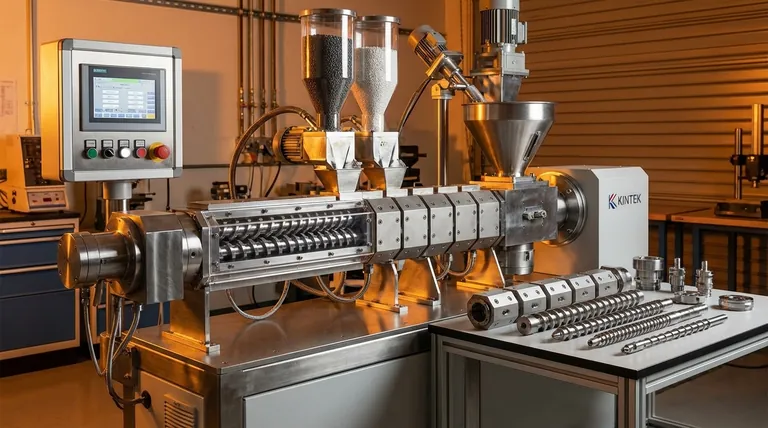

Visual Guide

Related Products

- Professional Cutting Tools for Carbon Paper Cloth Diaphragm Copper Aluminum Foil and More

- Lab Internal Rubber Mixer Rubber Kneader Machine for Mixing and Kneading

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Custom PTFE Teflon Parts Manufacturer for PTFE Measuring Cylinder 10/50/100ml

- Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

People Also Ask

- What is the purpose of a vulcanizing machine? Transform Rubber into High-Performance Parts

- What is the meaning of calendering? Achieve Superior Surface Finish and Material Uniformity

- What finishes are done using calendering technique? Achieve High Gloss, Embossing, and More

- What are the advantages of twin screw granulation? Achieve Superior Control and Consistency in Manufacturing

- How many types of rolling are there? A Guide to Metal Forming Processes

- What are the disadvantages of blown film extrusion? Overcoming Precision and Speed Limitations

- What is vulcanizing used for? Unlock the Strength and Durability of Rubber

- What are the different types of rubber mixing? Choose the Right Method for Your Production Scale