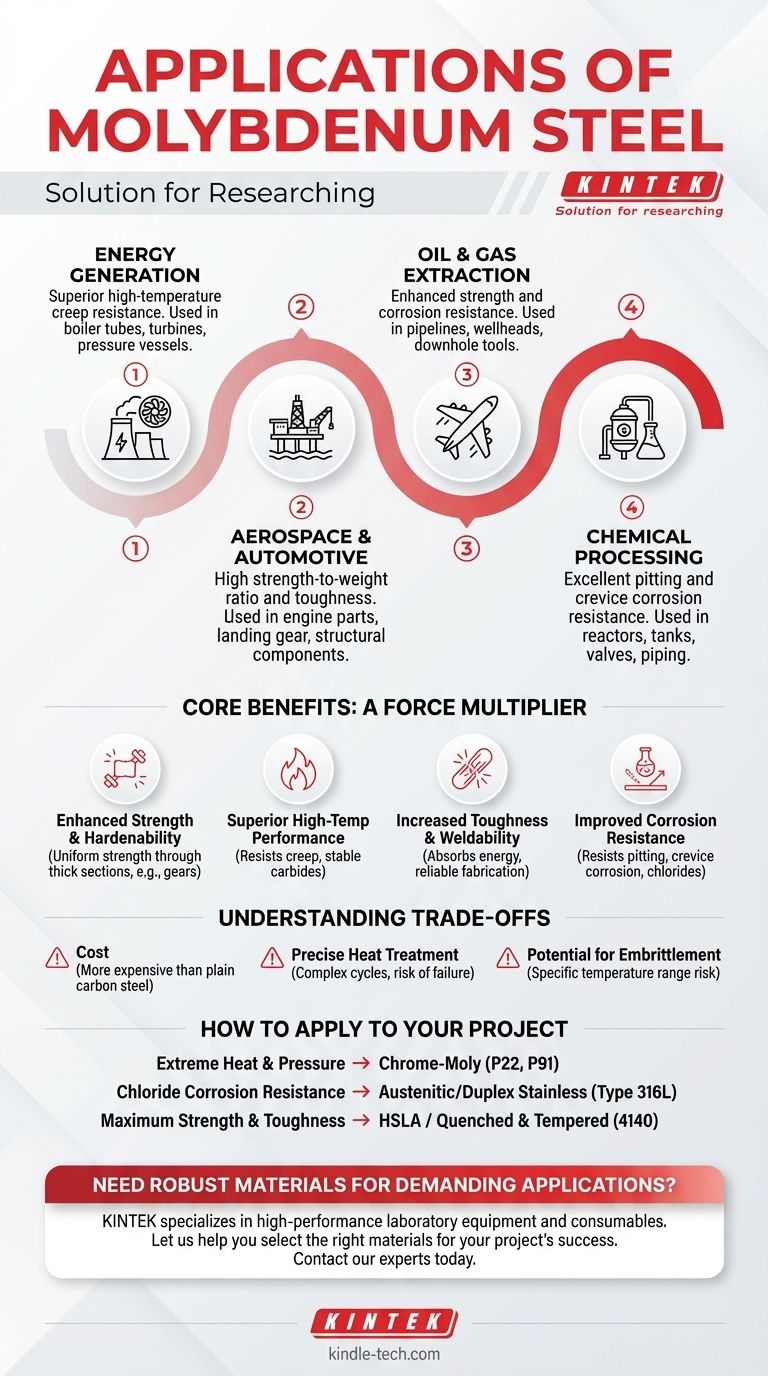

In short, molybdenum steel is used where standard steel would fail due to high heat, high pressure, or corrosive attack. Its primary applications are found in the most demanding sectors, including energy generation, oil and gas extraction, aerospace engineering, and automotive manufacturing for critical components like engine parts, pipelines, and turbine blades.

The decision to use molybdenum steel is a strategic one. You don't use it for its own sake; you use it as a targeted solution when the operational environment is too extreme for conventional carbon steels, making its higher cost a necessary investment in reliability and safety.

The Core Benefits of Adding Molybdenum to Steel

Molybdenum is rarely the primary alloying element in steel; instead, it acts as a powerful "force multiplier." Adding even small amounts (typically under 1%) dramatically enhances the properties imparted by other elements like chromium and nickel.

Enhanced Strength and Hardenability

Molybdenum significantly increases a steel's ability to be hardened through heat treatment. This property, known as hardenability, ensures that even very thick components can achieve high strength uniformly through their entire cross-section, not just at the surface.

This is critical for large gears, structural components, and pressure vessel walls that must bear immense loads without deforming.

Superior High-Temperature Performance

This is molybdenum's most famous contribution. It dramatically increases steel's resistance to "creep," which is the tendency of a material to slowly deform under long-term exposure to high temperatures and stress.

Molybdenum atoms form stable carbides within the steel's structure, pinning it in place and preventing it from weakening at elevated temperatures. This makes it indispensable for components inside boilers, steam turbines, and furnace parts like hearth rails.

Increased Toughness and Weldability

While many alloying elements increase strength at the cost of making the steel brittle, molybdenum can improve both strength and toughness—the material's ability to absorb energy and resist fracturing.

Furthermore, it helps mitigate the risks of embrittlement during welding, making the fabrication of high-strength structures more reliable and robust.

Improved Corrosion Resistance

When added to stainless steel (along with chromium and nickel), molybdenum provides a dramatic boost in resistance to pitting and crevice corrosion, particularly from chlorides found in marine environments and industrial chemicals.

This is why molybdenum-bearing stainless steel, such as Type 316, is the standard for chemical processing equipment, offshore platforms, and desalination plants.

Understanding the Trade-offs

While its benefits are significant, molybdenum steel is not a universal solution. Its selection involves clear engineering and economic trade-offs.

The Primary Factor: Cost

Molybdenum is a relatively expensive alloying element. This means molybdenum-bearing steels are significantly more costly than plain carbon or low-alloy steels.

Their use is only justified when the performance requirements—such as extreme heat or corrosion—make cheaper alternatives unsafe or unreliable.

The Need for Precise Heat Treatment

Achieving the desired properties in molybdenum steels requires more complex and tightly controlled heat treatment cycles compared to simpler steels.

Improper heating or cooling can fail to develop the intended microstructure or, in some cases, can lead to embrittlement, negating the benefits of the alloy.

Potential for Embrittlement

Certain grades of molybdenum steel can be susceptible to a phenomenon called "temper embrittlement" if held for long periods within a specific temperature range.

Engineers must be aware of these operational windows to prevent a gradual loss of toughness in components during their service life.

How to Apply This to Your Project

Your choice of a molybdenum-bearing alloy should be driven entirely by the primary problem you need to solve.

- If your primary focus is extreme heat and pressure: Look to chromium-molybdenum ("chrome-moly") steels like P22 or P91, which are the workhorses of the power generation and petrochemical industries.

- If your primary focus is chloride corrosion resistance: Your solution lies in austenitic stainless steels containing molybdenum, such as Type 316L, or even more advanced duplex stainless steels for more aggressive environments.

- If your primary focus is maximum strength and toughness: Consider high-strength, low-alloy (HSLA) steels or quenched and tempered alloy steels like 4140, where molybdenum enhances hardenability for critical mechanical parts.

Ultimately, molybdenum is the key that unlocks steel's performance in the most challenging engineering applications.

Summary Table:

| Application Area | Key Molybdenum Steel Benefit | Common Examples |

|---|---|---|

| Energy & Power Generation | Superior high-temperature creep resistance | Boiler tubes, turbine blades, pressure vessels |

| Oil & Gas Extraction | Enhanced strength and corrosion resistance | Pipelines, wellhead components, downhole tools |

| Aerospace & Automotive | High strength-to-weight ratio and toughness | Engine parts, landing gear, critical structural components |

| Chemical Processing | Excellent pitting and crevice corrosion resistance | Reactors, tanks, valves, piping systems |

Need robust materials for your most demanding applications?

The exceptional properties of molybdenum steel are critical for success in extreme environments. At KINTEK, we specialize in providing high-performance laboratory equipment and consumables that are built to withstand these very challenges. Our expertise ensures your operations in research, quality control, and material testing are supported by reliable, durable solutions.

Let us help you select the right materials and equipment for your project's success. Contact our experts today for a personalized consultation.

Visual Guide

Related Products

- High Temperature Wear-Resistant Alumina Al2O3 Plate for Engineering Advanced Fine Ceramics

- Automatic Laboratory Heat Press Machine

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

- High-Purity Titanium Foil and Sheet for Industrial Applications

- Advanced Engineering Fine Ceramics Boron Nitride (BN) Ceramic Parts

People Also Ask

- What is the maximum service temperature for brazed joints? Unlock the Key to Joint Reliability and Performance

- What is the best prevention for CVD? A Lifelong Strategy for Optimal Heart Health

- What is the purpose of reactive sputtering? Synthesize High-Performance Compound Thin Films

- Why is biomass energy not as efficient as fossil fuels? Uncover the key limitations in energy density and lifecycle.

- What is the function of a magnetic stirrer in sol-gel catalyst synthesis? Ensure Perfect Zeolite-Titanate Uniformity

- What elements cannot be detected by XRF? Understanding the Limits of Light Element Analysis

- Is biomass cheaper than other energy sources? Unpacking the True Cost of Biomass Energy

- Does a 2 stage furnace run all the time? It's Designed for Longer, More Efficient Cycles