In short, ASTM standard sieves are a series of precision-made mesh screens used to separate materials by particle size, all conforming to the detailed specifications of the ASTM E11 standard. These specifications dictate not only the exact size of the square openings in the wire mesh but also the wire diameter, the material of construction, and the statistical uniformity of the weave. This rigorous standardization ensures that particle size analysis results are accurate, consistent, and reproducible across different labs and industries.

The critical takeaway is that ASTM sieves are not just a random collection of screens. They are a carefully designed system where the opening sizes of sequential sieves follow a precise mathematical progression, allowing for a standardized and meaningful analysis of particle size distribution.

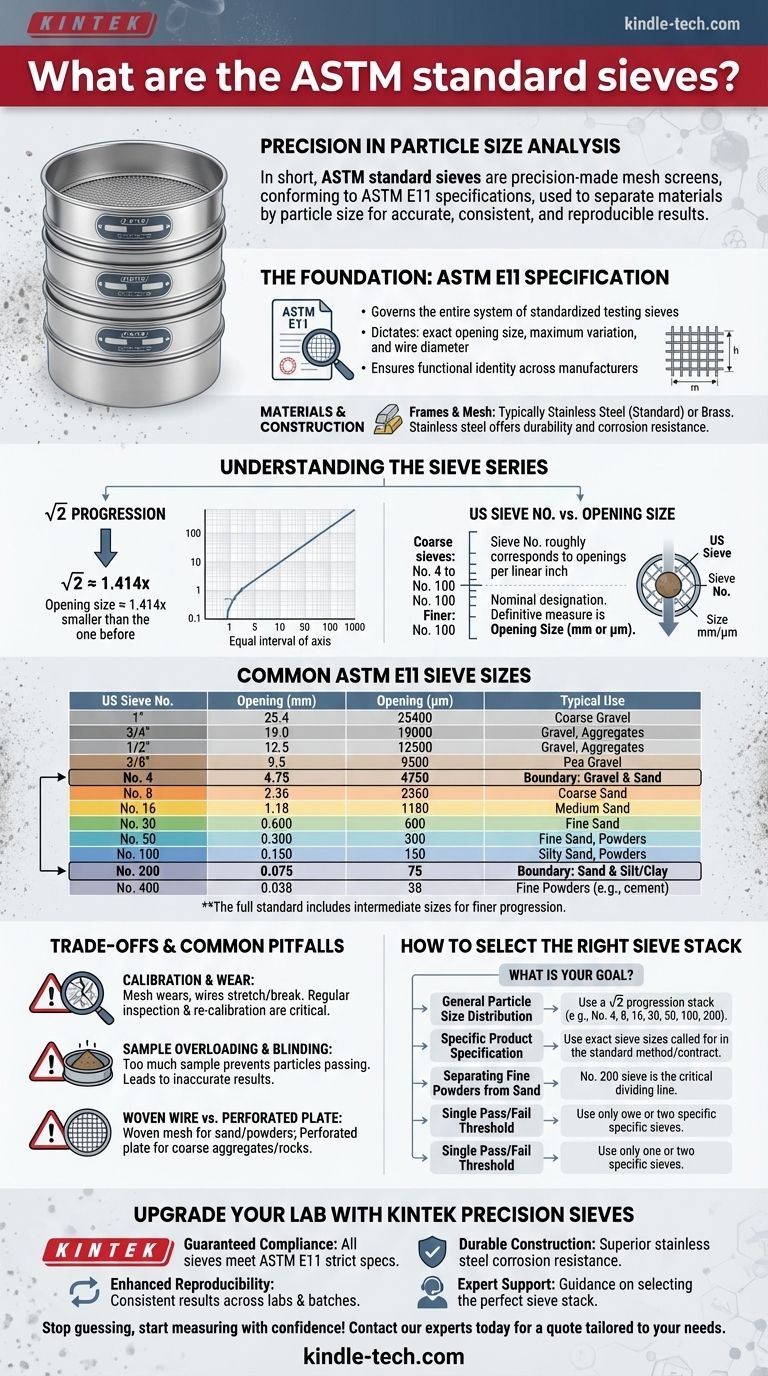

The Foundation: ASTM E11 Specification

The entire system of standardized testing sieves is governed by ASTM E11, "Standard Specification for Woven Wire Test Sieve Cloth and Test Sieves." This document is the bedrock of reliable particle analysis.

What the Standard Dictates

ASTM E11 goes far beyond simply listing opening sizes. It ensures the physical quality of the sieve itself, specifying tolerances for the average opening size, the maximum variation for individual openings, and the diameter of the wire used to weave the cloth.

This ensures that a No. 40 sieve from one manufacturer is functionally identical to a No. 40 sieve from another, which is essential for comparing results.

Materials and Construction

Sieves are typically constructed with brass or stainless steel frames and mesh. Stainless steel is more durable, corrosion-resistant, and is the standard for most modern laboratory and quality control applications. The frames come in standard diameters (e.g., 3, 8, and 12 inches) and heights (full or half) to fit into mechanical sieve shakers.

Understanding the Sieve Series

The genius of the ASTM system lies in its logical progression of opening sizes. This allows for the creation of a particle size distribution curve, not just a simple pass/fail test.

The Principle of the √2 Progression

The primary set of standard sieves is based on a √2 (square root of 2) progression. This means the opening size of each successive sieve in the series is approximately 1.414 times smaller than the one before it.

When you plot particle sizes, a logarithmic scale is often most useful. This geometric progression creates equal intervals on a log scale, making data analysis and graphing intuitive.

US Sieve No. vs. Opening Size

The "Sieve Number" can be confusing. For coarser sieves (e.g., No. 4 to No. 100), the number roughly corresponds to the number of openings per linear inch.

For finer sieves (below No. 100), the number is a nominal designation that no longer directly relates to openings per inch. In all cases, the definitive measure is the opening size in millimeters (mm) or micrometers (µm).

Common ASTM E11 Sieve Sizes

This table shows a selection of common sieves from the primary series. The full standard includes intermediate sizes that create a finer progression.

| US Sieve No. | Opening (mm) | Opening (µm) | Typical Use |

|---|---|---|---|

| 1" | 25.4 | 25400 | Coarse Gravel |

| 3/4" | 19.0 | 19000 | Gravel, Aggregates |

| 1/2" | 12.5 | 12500 | Gravel, Aggregates |

| 3/8" | 9.5 | 9500 | Pea Gravel |

| No. 4 | 4.75 | 4750 | Defines boundary between gravel and sand |

| No. 8 | 2.36 | 2360 | Coarse Sand |

| No. 16 | 1.18 | 1180 | Medium Sand |

| No. 30 | 0.600 | 600 | Fine Sand |

| No. 50 | 0.300 | 300 | Fine Sand, Powders |

| No. 100 | 0.150 | 150 | Silty Sand, Powders |

| No. 200 | 0.075 | 75 | Defines boundary between sand and silt/clay |

| No. 400 | 0.038 | 38 | Fine Powders (e.g., cement) |

Understanding the Trade-offs and Common Pitfalls

Using sieves correctly is as important as having the right ones. Inaccurate results are often caused by procedural errors, not faulty equipment.

Calibration and Wear

Sieve mesh can wear down, and wires can stretch or break, leading to larger-than-specified openings. Regular visual inspection for damage and periodic re-calibration or certification against a master set is critical for quality control.

Sample Overloading and Blinding

The most common error is placing too much sample material on a sieve. This prevents individual particles from having a chance to pass through an opening, a phenomenon called sieve blinding. It leads to an artificially high amount of material being retained on the sieve, skewing the results.

Woven Wire vs. Perforated Plate

The common image of a sieve is woven wire mesh, used for sand, powders, and fine aggregates. For testing very coarse materials like large rocks and construction aggregates, perforated plate sieves with round or square holes punched in sheet metal are used instead.

How to Select the Right Sieve Stack

The sieves you need depend entirely on the material you are analyzing and the goal of your test.

- If your primary focus is a general particle size distribution: Use a standard "stack" of sieves from the √2 progression, such as No. 4, 8, 16, 30, 50, 100, and 200, to get a comprehensive curve.

- If your primary focus is meeting a specific product specification: You must use the exact sieve sizes called for in the standard method or contract (e.g., a specific DOT or construction material spec).

- If your primary focus is separating fine powders from sand: The No. 200 sieve is the most critical, as it is the standard dividing line between sand and finer "fines" (silt and clay).

- If your primary focus is determining a single "pass/fail" threshold: You may only need one or two specific sieves to check if a material is finer or coarser than a required size.

Ultimately, mastering sieve analysis comes from understanding that the ASTM standards provide a common language for describing the world of particles.

Summary Table:

| US Sieve No. | Opening (mm) | Opening (µm) | Typical Use |

|---|---|---|---|

| 1" | 25.4 | 25400 | Coarse Gravel |

| No. 4 | 4.75 | 4750 | Defines boundary between gravel and sand |

| No. 8 | 2.36 | 2360 | Coarse Sand |

| No. 30 | 0.600 | 600 | Fine Sand |

| No. 100 | 0.150 | 150 | Silty Sand, Powders |

| No. 200 | 0.075 | 75 | Defines boundary between sand and silt/clay |

| No. 400 | 0.038 | 38 | Fine Powders (e.g., cement) |

Upgrade your lab's particle analysis with precision ASTM sieves from KINTEK!

Are you tired of inconsistent particle size results? KINTEK specializes in high-quality laboratory equipment and consumables, including a full range of ASTM E11 compliant test sieves in stainless steel and brass. We serve laboratories across industries who demand accuracy, consistency, and reproducibility in their testing.

By choosing KINTEK, you benefit from:

- Guaranteed Compliance: All our sieves meet strict ASTM E11 specifications for opening size, wire diameter, and weave uniformity.

- Enhanced Reproducibility: Ensure your results are consistent and comparable across different labs and batches.

- Durable Construction: Our stainless steel sieves offer superior corrosion resistance and longevity.

- Expert Support: Get guidance on selecting the perfect sieve stack for your specific material and application.

Stop guessing and start measuring with confidence. Contact our experts today to discuss your sieve requirements and get a quote tailored to your laboratory's needs!

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Three-dimensional electromagnetic sieving instrument

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Multifunctional Small Speed-Adjustable Horizontal Mechanical Shaker for Lab

- Vibratory Sieve Shaker Machine Dry Three-Dimensional Vibrating Sieve

People Also Ask

- What is the process of sieving? A Step-by-Step Guide to Accurate Particle Size Analysis

- What is the purpose of using precision standard sieves in powder granulation? Maximize Density and Structural Isotropy

- What is sieve analysis used for? Ensure Material Quality and Consistency with Accurate Particle Sizing

- Why is a standard mesh sieving system necessary for polyester methanolysis? Ensure Precise Reaction Kinetics

- What are three industrial uses for sieving? Ensure Quality and Safety in Your Production Process

- What is the basis of selecting the size of the sieves for the sieve analysis of the given aggregates? Follow the Standard for Accurate Gradation

- What is the function of a sieve in a laboratory? Master Particle Size Analysis for Quality Control

- Is a dry sieve analysis more accurate than a washed sieve analysis? Choosing the Right Method for Your Material