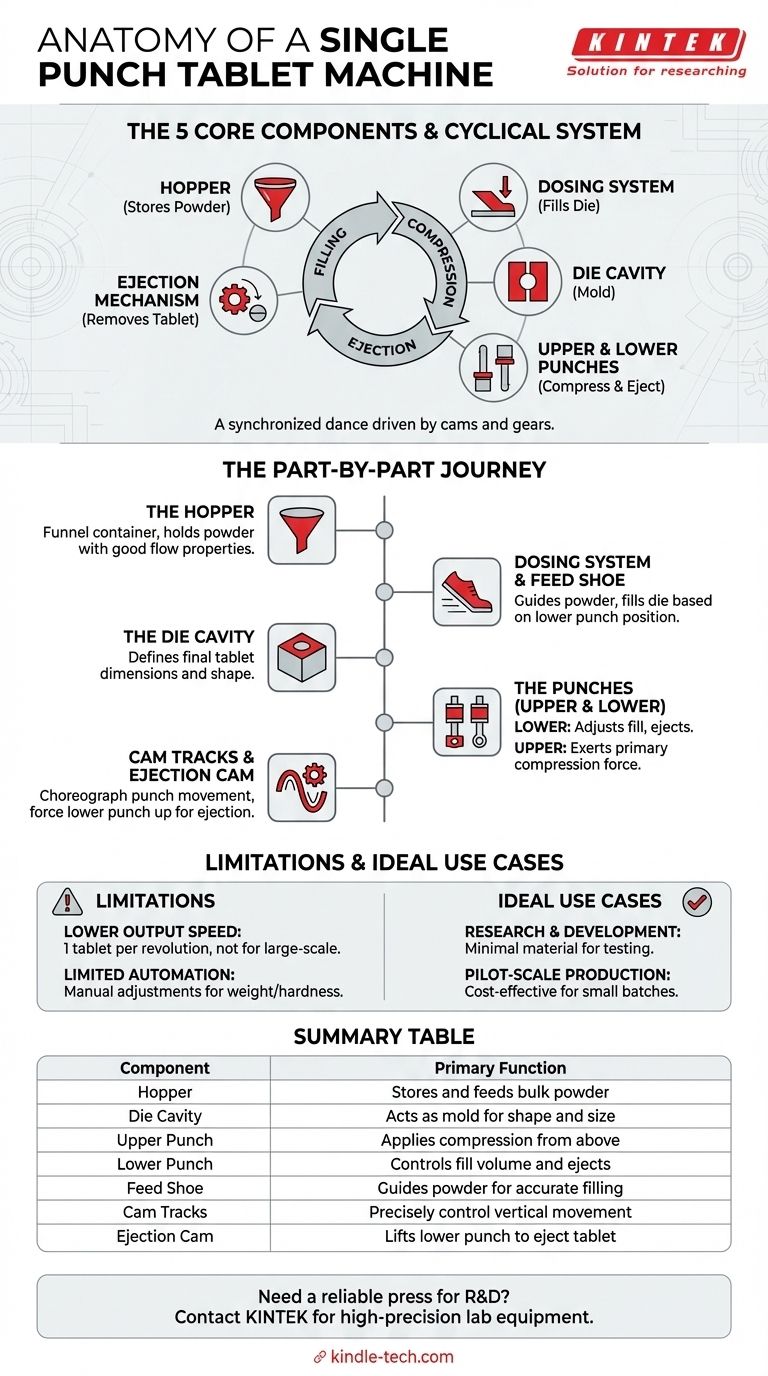

At its core, a single punch tablet machine operates using five primary components. These are the hopper, which stores the bulk powder; the die cavity, which serves as the mold for the tablet; the upper and lower punches, which compress the powder; a dosing system to fill the die; and an ejection mechanism to remove the finished tablet. These parts work in a precise mechanical sequence to transform loose powder into a solid, uniform tablet.

A single punch tablet press is not just a collection of parts, but a cyclical system. Understanding that this cycle consists of three distinct phases—filling, compression, and ejection—is the key to grasping how each component contributes to the final product.

The Tablet Compression Cycle: A Part-by-Part Journey

To truly understand the machine, we must follow the path of the powder as it becomes a tablet. The entire operation is a synchronized dance between the components, driven by a series of cams and gears.

The Hopper: The Starting Point

The hopper is the funnel-shaped container at the top of the machine. Its sole function is to hold the powder or granule mixture that will be compressed into tablets. The material must have good flow properties to ensure it feeds consistently into the machine.

The Dosing System and Feed Shoe: Measuring the Dose

Below the hopper, a feed shoe (sometimes called a dosing plow) moves back and forth. Its job is to guide powder from the hopper and push it over the die opening.

The actual dose is not measured by the feed shoe itself, but by the volume of the die cavity. The position of the lower punch at this stage determines the fill depth, which in turn sets the weight of the tablet.

The Die Cavity: The Forming Mold

The die is a precision-machined metal block with a hole through its center, known as the die cavity. This cavity is where the powder is compressed. The diameter and shape of the die cavity define the final dimensions and shape of the tablet.

The Punches (Upper and Lower): The Force of Compression

The punches are the steel rods that apply pressure to the powder.

- The Lower Punch first serves to close the bottom of the die cavity and adjust the fill volume. After compression, it rises to push the finished tablet out.

- The Upper Punch descends into the die cavity after it is filled with powder. It exerts the primary force required to consolidate the powder particles into a solid tablet.

The Cam Tracks: Choreographing the Movement

The punches do not move randomly; their vertical motion is meticulously controlled by cam tracks. As the machine's main shaft rotates, the punches follow these tracks, which dictate the precise timing for filling, compressing, and ejecting the tablet.

The Ejection Cam: Finalizing the Process

After the upper punch retracts, a specific section of the cam track, the ejection cam, forces the lower punch upwards. This pushes the finished tablet up and out of the die cavity, bringing it level with the die table surface. The feed shoe then sweeps the tablet away on its next cycle to fill the die again.

Understanding the Limitations of a Single Punch Press

While effective, this design is not suited for all purposes. Its mechanical simplicity comes with inherent trade-offs that are critical to understand.

Lower Output Speed

The most significant limitation is speed. Because it produces only one tablet per 360-degree revolution of the crankshaft, its output is very low compared to modern rotary presses. This makes it unsuitable for large-scale commercial manufacturing.

Limited Automation

Most single punch presses are manually operated or semi-automatic. Adjustments to tablet weight (by changing the lower punch fill position) and hardness (by changing the upper punch pressure) are typically done by hand, requiring a skilled operator.

Ideal for Specific Use Cases

These limitations become advantages in certain contexts. The low material consumption and simple setup make single punch presses the ideal choice for research and development, where only small batches of tablets are needed for testing. They are also excellent for pilot-scale production and training purposes.

Making the Right Choice for Your Goal

Selecting the right machine depends entirely on your objective. The single punch press excels in simplicity and precision for small-scale work.

- If your primary focus is Research & Development: This is the perfect machine, as it requires minimal material for formulation testing and process validation.

- If your primary focus is Small-Scale or Pilot Production: A single punch press is a cost-effective solution for producing limited quantities of products like nutraceuticals or for clinical trials.

- If your primary focus is High-Volume Manufacturing: This machine is not suitable; you must use a multi-station rotary tablet press to meet commercial production demands.

By understanding how these core components work in concert, you can effectively operate the machine and troubleshoot the entire tablet manufacturing process.

Summary Table:

| Component | Primary Function |

|---|---|

| Hopper | Stores and feeds bulk powder into the machine |

| Die Cavity | Acts as the mold that defines the tablet's shape and size |

| Upper Punch | Applies compression force from above to form the tablet |

| Lower Punch | Controls fill volume and ejects the finished tablet |

| Feed Shoe / Dosing System | Guides powder over the die for accurate filling |

| Cam Tracks | Precisely control the vertical movement of the punches |

| Ejection Cam | Lifts the lower punch to push the tablet out of the die |

Need a reliable single punch tablet press for your R&D or pilot-scale production? KINTEK specializes in high-precision lab equipment, including tablet presses designed for accuracy and ease of use in research and small-batch manufacturing. Whether you're developing new formulations or producing limited-run nutraceuticals, our machines ensure consistent, uniform tablets with minimal material waste. Contact our experts today to find the perfect solution for your laboratory needs!

Visual Guide

Related Products

- Single Punch Electric Tablet Press Machine TDP Tablet Punching Machine

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Single Punch Manual Tablet Press Machine TDP Tablet Punching Machine

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

- Lab Scale Rotary Single Punch Tablet Press Machine TDP Tablet Punching Machine

People Also Ask

- What is die compression ratio? Master Your Pelleting Process for Optimal Quality & Efficiency

- What are the two classifications of press machines? Single Punch vs. Rotary Presses Explained

- What are the advantages of tablet press machine? Achieve High-Speed, Consistent Production

- How does a larger area affect the pressure of the same force? Master the Physics of Force Distribution

- What are the different pill presses? Choose the Right Machine for Your Lab or Production Scale