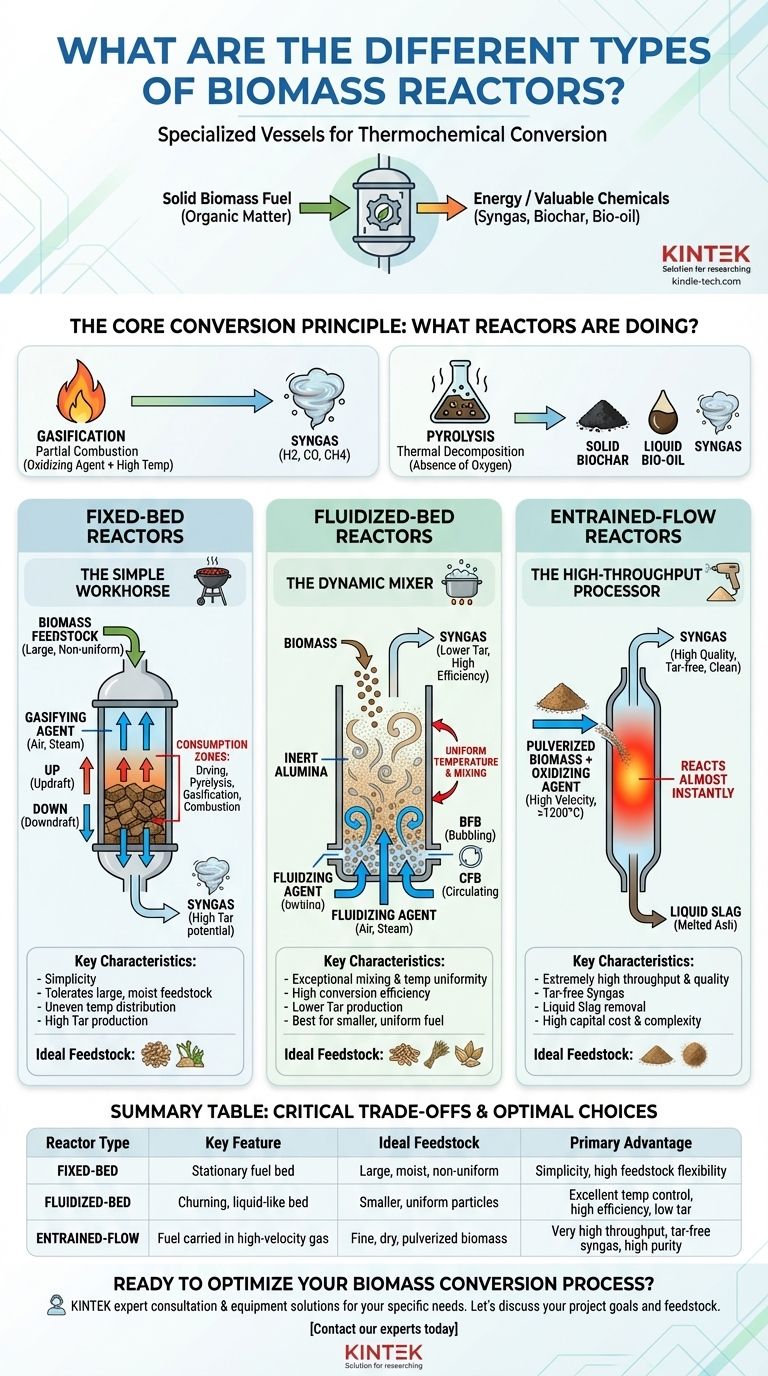

At their core, biomass reactors are specialized vessels designed for the thermochemical conversion of organic matter into energy or valuable chemicals. The primary types are distinguished by how the solid biomass fuel interacts with the reactive gases and heat inside the vessel: fixed-bed, fluidized-bed, and entrained-flow reactors. Each design represents a different engineering approach to optimizing this complex process.

The "best" biomass reactor does not exist in a vacuum. The optimal choice is always a direct function of your specific biomass feedstock—its size, moisture, and uniformity—and your desired end product, whether that's heat, power, or chemical feedstocks.

The Core Conversion Principle: What Are Reactors Doing?

Before examining the hardware, it's crucial to understand the fundamental process. Most biomass reactors facilitate gasification or pyrolysis.

Gasification and Pyrolysis

Gasification uses a controlled amount of an oxidizing agent (like air, oxygen, or steam) to partially combust biomass at high temperatures. This process converts the solid fuel into a combustible gas mixture called syngas, composed primarily of hydrogen, carbon monoxide, and methane.

Pyrolysis is the thermal decomposition of biomass in the complete absence of oxygen, producing a mix of solid biochar, liquid bio-oil, and syngas. The reactor type heavily influences which of these products is maximized.

Fixed-Bed Reactors: The Simple Workhorse

This is the oldest and simplest reactor design. As the name implies, the biomass feedstock forms a stationary, or "fixed," bed within the reactor.

How It Works

Imagine a simple charcoal grill. You load the solid fuel (briquettes or wood chunks), and the gasifying agent (air) flows up or down through the packed bed. The fuel is slowly consumed as distinct zones of drying, pyrolysis, gasification, and combustion establish themselves within the bed.

Key Characteristics

Fixed-bed reactors are known for their simplicity and tolerance for large, non-uniform feedstock particles, including wood chips and agricultural waste with high moisture content. Their primary drawback is the potential for uneven temperature distribution and the production of tars, which can complicate downstream processes.

Common Sub-types

There are two main configurations:

- Updraft: The gasifying agent flows up, counter-current to the fuel moving down. This is very simple but produces a high-tar syngas.

- Downdraft: The gasifying agent flows down, co-current with the fuel. This forces the volatile tars to pass through the hot combustion zone, "cracking" them and resulting in a much cleaner syngas, but it requires a more uniform feedstock.

Fluidized-Bed Reactors: The Dynamic Mixer

This design is a significant leap in complexity and performance, behaving more like a boiling liquid than a static pile of solids.

How It Works

Picture a pot filled with sand. If you blow enough air up through the bottom, the sand will begin to churn and bubble as if it were boiling. In a fluidized-bed reactor, biomass particles are fed into a hot bed of inert material (like sand or alumina) that is being "fluidized" by the gasifying agent.

Key Characteristics

This constant mixing creates exceptionally uniform temperature distribution and excellent heat transfer throughout the reactor. This leads to higher conversion efficiency and lower tar production compared to fixed-bed designs. They are best suited for smaller, relatively uniform fuel particles.

Common Sub-types

- Bubbling Fluidized Bed (BFB): Operates at lower gas velocities, with distinct bubbles of gas rising through the bed. It's a robust and widely used technology.

- Circulating Fluidized Bed (CFB): Uses higher gas velocities to carry the bed material and unreacted fuel out of the reactor into a cyclone, which separates the solids and returns them to the bottom. This circulation provides even better mixing and longer residence time for the fuel, maximizing conversion.

Entrained-Flow Reactors: The High-Throughput Processor

This is the most advanced and intensive type of reactor, operating more like a rocket engine's combustion chamber than a simple furnace.

How It Works

Think of a sandblaster. Fine, dry, pulverized biomass (like flour) is injected along with the oxidizing agent into the reactor. The particles are carried, or "entrained," in the hot gas flow and react almost instantaneously at very high temperatures (typically >1200°C).

Key Characteristics

Entrained-flow reactors offer extremely high throughput and produce a very clean, high-quality, tar-free syngas ideal for producing liquid fuels or chemicals. The high operating temperatures cause the ash to melt into a liquid slag, which is easier to remove. However, their major limitation is the strict requirement for a very fine, dry, and uniform feedstock, which necessitates significant and costly pre-processing.

Understanding the Critical Trade-offs

Choosing a reactor involves navigating a series of fundamental engineering trade-offs. There is no universally superior option.

Feedstock Flexibility vs. Pre-processing Costs

Fixed-bed reactors are the most forgiving, accepting large and moist biomass with minimal preparation. In contrast, entrained-flow reactors demand extensive pre-processing (drying, grinding, pulverizing), which adds significant capital and operational expense. Fluidized-beds sit in the middle.

Throughput and Efficiency vs. Complexity

Entrained-flow reactors boast the highest throughput and conversion efficiency, but they are also the most complex and expensive to build and operate. Fixed-bed reactors are simple and cheap but have lower throughput and are prone to channeling and uneven performance.

Product Quality vs. Operating Conditions

If the goal is high-purity syngas for chemical synthesis, the high-temperature, low-tar output of an entrained-flow reactor is unmatched. If the goal is simply to produce heat or power from local waste, the lower-quality gas from a simpler fixed-bed or fluidized-bed reactor may be perfectly adequate and far more economical.

Making the Right Choice for Your Goal

Your selection process must begin with a clear definition of your input material and your desired output.

- If your primary focus is processing diverse, unprepared feedstock (like wood chunks or municipal solid waste): A fixed-bed reactor offers the greatest flexibility and lowest pre-processing requirements.

- If your primary focus is achieving a balance of efficiency, good fuel flexibility, and scalable power generation: A fluidized-bed reactor, particularly a CFB, represents the most versatile and commercially proven middle ground.

- If your primary focus is generating high-quality, tar-free syngas for liquid fuels or chemical synthesis: An entrained-flow reactor is the superior choice, provided you can prepare a fine, dry feedstock.

Ultimately, a clear definition of your inputs and desired outputs will illuminate the most effective path forward.

Summary Table:

| Reactor Type | Key Feature | Ideal Feedstock | Primary Advantage |

|---|---|---|---|

| Fixed-Bed | Stationary fuel bed | Large, moist, non-uniform particles (wood chips, waste) | Simplicity, high feedstock flexibility |

| Fluidized-Bed | Churning, liquid-like bed of inert material | Smaller, uniform particles | Excellent temperature control, high efficiency, low tar |

| Entrained-Flow | Fuel particles carried in high-velocity gas stream | Fine, dry, pulverized biomass | Very high throughput, tar-free syngas, high purity |

Ready to Optimize Your Biomass Conversion Process?

Choosing the right reactor is critical to the success of your project. The team at KINTEK understands the complex trade-offs between feedstock flexibility, product quality, and operational costs. We specialize in providing robust laboratory equipment and expert consultation to help you test, scale, and implement the ideal biomass conversion solution for your specific needs—whether you're focused on sustainable energy production or creating valuable chemical feedstocks.

Let's discuss your project goals and feedstock to determine the most efficient path forward.

Contact our experts today to explore how KINTEK's solutions can enhance your research and development.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

People Also Ask

- What is sintering of clay materials? The Science of Turning Clay into Durable Ceramics

- What is the function of a laboratory orbital shaker in methylene blue adsorption kinetics? Optimize Your Research

- Does metal expand on heating or cooling? The Science of Thermal Expansion Explained

- What is a hot air oven for a chemistry lab? Master Dry Heat Sterilization & Drying

- What are the driving forces of sintering? Understanding the Thermodynamics for Better Materials

- What is the difference between sintering and powder metallurgy? Sintering is a Key Step Within the Process

- What is the energy required for sputtering? Achieve Precise Thin Film Deposition

- What is the grain size of sputter coating? Control Nanoscale Structure for Your Application