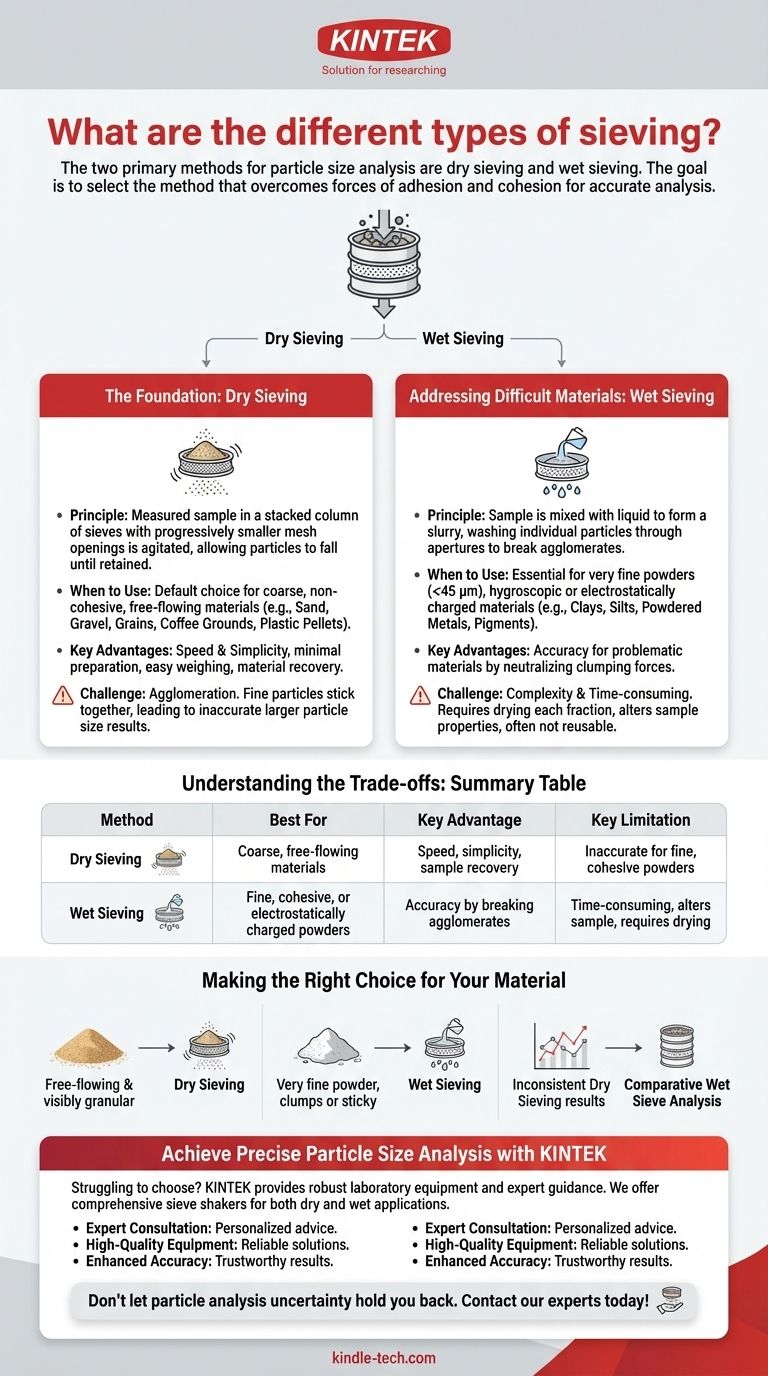

The two primary methods for particle size analysis are dry sieving and wet sieving. Dry sieving is the most common approach, used for materials that flow freely without clumping. Wet sieving is a specialized technique required for fine, cohesive, or electrostatically charged powders that would otherwise agglomerate and produce inaccurate results.

Your choice between dry and wet sieving is determined entirely by the physical properties of your material. The goal is to select the method that overcomes forces of adhesion and cohesion, ensuring that each particle is measured individually for an accurate and repeatable analysis.

The Foundation: Dry Sieving

Dry sieving is the standard method for determining the particle size distribution of a granular material. It is a straightforward mechanical process that serves as the baseline for most analyses.

The Principle of Dry Sieving

A measured sample of the material is placed on the top sieve in a stacked column of test sieves with progressively smaller mesh openings. The entire stack is then agitated by a mechanical shaker, allowing particles to fall through the apertures until they are retained by a sieve with a mesh too fine for them to pass.

When to Use Dry Sieving

This method is the default choice for materials that are coarse, non-cohesive, and free-flowing. Think of materials like sand, gravel, grains, coffee grounds, and plastic pellets. If the particles do not naturally stick to each other, dry sieving is typically sufficient.

Key Advantages

The primary benefits of dry sieving are its speed and simplicity. It requires minimal sample preparation, and the separated particle fractions can be easily weighed. Furthermore, the material is not altered during the process and can often be recovered for other uses.

Addressing Difficult Materials: Wet Sieving

When particles are very fine or prone to clumping, dry sieving fails. Wet sieving introduces a liquid to the process to overcome the intermolecular forces that cause particles to stick together.

The Principle of Wet Sieving

In wet sieving, the sample is mixed with a liquid (typically water, sometimes with a wetting agent) to form a suspension. This slurry is poured onto the top sieve, and the liquid helps to wash individual particles through the apertures. This breaks down agglomerates and eliminates static electricity, ensuring a true size separation.

When to Use Wet Sieving

Wet sieving is essential for materials that are difficult to separate when dry. This includes very fine powders (typically below 45 µm), materials that are hygroscopic (absorb moisture), or those that are prone to electrostatic charging. Examples include clays, silts, powdered metals, and certain pigments.

Key Advantages

The main advantage of wet sieving is accuracy for problematic materials. By neutralizing the forces that cause clumping, it provides a far more reliable particle size distribution for cohesive powders than a dry analysis ever could.

Understanding the Trade-offs

Choosing the wrong method can lead to significantly flawed data. Understanding the limitations of each approach is critical for ensuring the integrity of your results.

The Challenge of Agglomeration

The primary failure mode of dry sieving is agglomeration. Fine particles stick together due to moisture or electrostatic forces, forming what are effectively larger particles. These clumps are then retained on a coarser sieve than the individual particles would be, skewing the results toward a larger particle size distribution.

The Complexity of Wet Sieving

While more accurate for fine powders, wet sieving is a more involved and time-consuming process. It requires a liquid that will not dissolve or react with the sample. Afterward, each sieved fraction must be carefully dried in an oven before it can be weighed, adding significant time and effort to the analysis.

Equipment and Sample Integrity

Modern sieve shakers often support both methods, but wet sieving may require specialized lids, receivers, and a water supply. A crucial trade-off is that after wet sieving and drying, the sample's properties may be altered, and it is often not suitable for reuse.

Making the Right Choice for Your Material

Your material's characteristics are the sole determinant of the correct sieving method. A simple visual inspection can often guide your initial decision.

- If your material is free-flowing and visibly granular (like sand or salt): Dry sieving is the correct starting point for its speed, simplicity, and efficiency.

- If your material is a very fine powder that clumps or feels sticky (like flour or clay): Wet sieving is necessary to break apart agglomerates and achieve an accurate analysis.

- If your dry sieving results are inconsistent or seem incorrect: Performing a comparative wet sieve analysis is the definitive way to validate whether agglomeration is skewing your data.

Selecting the appropriate sieving method is the most critical step toward achieving reliable and repeatable particle size data.

Summary Table:

| Method | Best For | Key Advantage | Key Limitation |

|---|---|---|---|

| Dry Sieving | Coarse, free-flowing materials (e.g., sand, grains) | Speed, simplicity, sample recovery | Inaccurate for fine, cohesive powders |

| Wet Sieving | Fine, cohesive, or electrostatically charged powders (e.g., clay, pigments) | Accuracy for problematic materials by breaking agglomerates | Time-consuming, alters sample, requires drying |

Achieve Precise Particle Size Analysis with KINTEK

Struggling to choose the right sieving method for your materials? The accuracy of your particle size distribution data is critical for product quality and process efficiency. KINTEK specializes in providing robust laboratory equipment and expert guidance to overcome these challenges.

We offer a comprehensive range of sieve shakers and accessories designed for both dry and wet sieving applications. Our team can help you select the perfect solution to ensure reliable, repeatable results for your specific materials—from free-flowing granules to challenging fine powders.

Let KINTEK empower your laboratory:

- Expert Consultation: Get personalized advice to select the optimal sieving method.

- High-Quality Equipment: Find reliable sieve shakers and consumables for any application.

- Enhanced Accuracy: Ensure your particle analysis is precise and trustworthy.

Don't let particle analysis uncertainty hold you back. Contact our experts today to discuss your lab's needs and find the ideal sieving solution!

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Three-dimensional electromagnetic sieving instrument

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Wet Three-Dimensional Vibratory Sieve Shaker Machine

People Also Ask

- What are the hazards of sieve shakers? Mitigate Risks from Dust, Noise, and Data Errors

- What is the purpose of using a sieve shaker in sieve analysis? Achieve Accurate Particle Size Data

- How does a laboratory shaker or extractor function during 133Ba adsorption? Optimize Your Kinetic Evaluation

- What is vibratory sieving? Achieve Precise, Reproducible Particle Size Analysis

- What is the shaking machine for sieve analysis? Ensure Accurate & Repeatable Particle Size Results

- How do you use a sieve shaker? Master Particle Size Analysis for Quality Control

- How many types of vibrating screens are there? Unlock the Key to Efficient Material Separation

- What are the different types of sieve shakers? Match the Shaker to Your Material for Accurate Particle Analysis