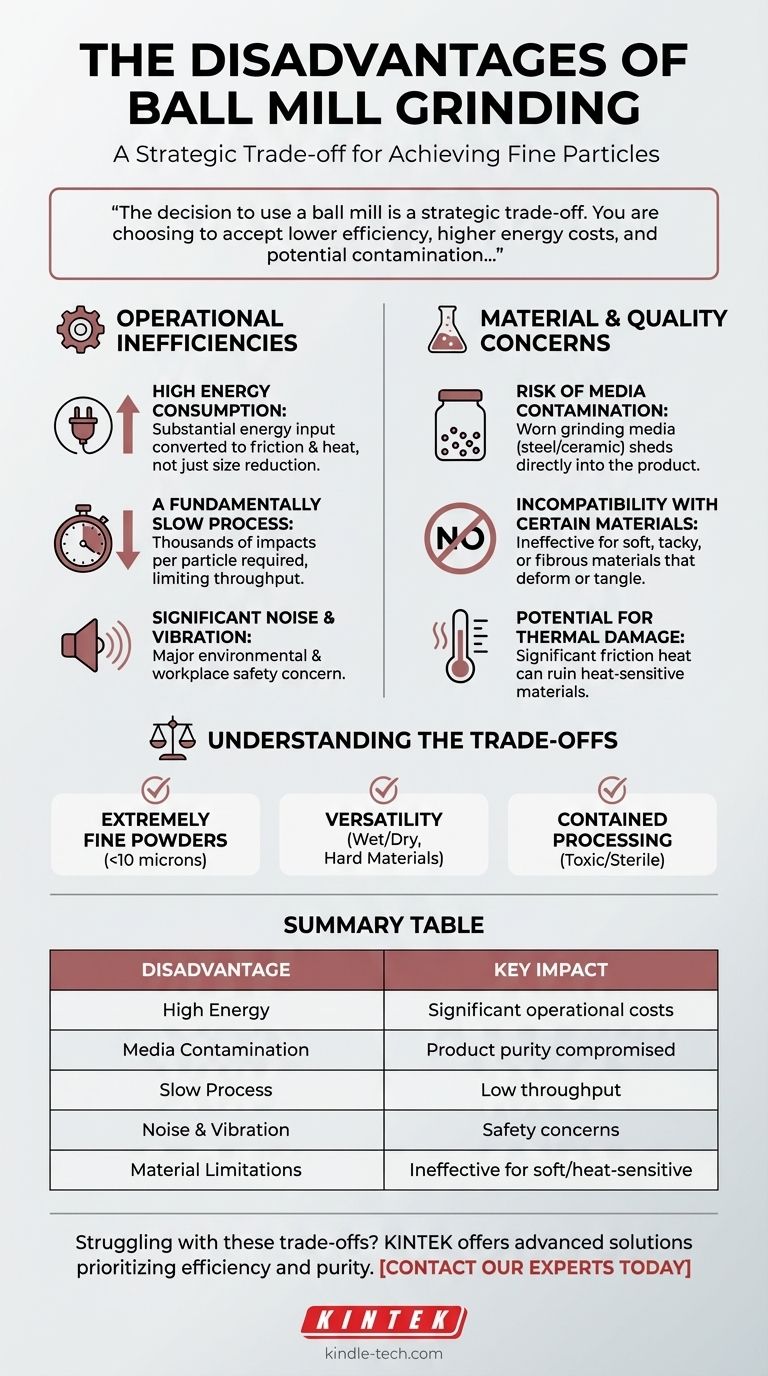

While ball mills are a foundational tool for grinding materials into fine powders, they come with significant operational drawbacks. The primary disadvantages are their slow processing speed, high energy consumption, considerable noise and vibration, inability to process certain material types, and a persistent risk of product contamination from the grinding media itself.

The decision to use a ball mill is a strategic trade-off. You are choosing to accept lower efficiency, higher energy costs, and potential contamination in exchange for the unique ability to produce extremely fine particles from hard or abrasive materials.

The Core Operational Inefficiencies

A ball mill operates on the principle of brute-force impact and attrition. While effective, this mechanical action brings inherent inefficiencies that impact your operational costs and environment.

High Energy Consumption

The process of lifting and tumbling heavy grinding media (steel or ceramic balls) and the material charge requires a substantial and continuous input of energy. This energy is largely converted into friction and heat, not just particle size reduction, making ball mills one of the more energy-intensive grinding methods.

A Fundamentally Slow Process

Achieving a very fine powder is a game of probability and repetition. Each particle must be struck thousands of times to be fractured down to the micron scale. This makes ball milling an inherently slow, and often batch-oriented, process, limiting its throughput for large-scale production.

Significant Noise and Vibration

The constant tumbling of heavy balls inside a rotating metal drum produces considerable noise and strong vibrations. While using rubber liners or media can dampen this, it remains a major environmental and workplace safety concern that often requires special infrastructure or isolation.

Material and Product Quality Concerns

Beyond operational costs, the grinding mechanism itself can directly compromise the final product, creating challenges for high-purity or sensitive applications.

The Inevitable Risk of Media Contamination

The grinding action is based on friction and impact, which causes wear on both the grinding media and the internal lining of the mill. This worn material—whether it's iron, steel, or ceramic—is shed directly into your product. This contamination is a critical failure point for applications in pharmaceuticals, food, or high-purity electronics.

Incompatibility with Certain Materials

Ball mills are ineffective for materials that do not fracture under impact. Soft, tacky, or fibrous materials are particularly problematic. Soft materials will deform or smear, coating the grinding balls and preventing further grinding. Fibrous materials tend to tangle and absorb impacts rather than break apart.

Potential for Thermal Damage

The immense friction generated during milling produces significant heat. For heat-sensitive materials, this can be disastrous, leading to melting, chemical degradation, or altered physical properties. This effectively ruins the product quality before the desired particle size is even achieved.

Understanding the Trade-offs

Despite these clear disadvantages, ball mills remain a vital tool because their strengths are highly specific and often non-negotiable for certain goals. Their drawbacks must be weighed against their primary benefits.

The Goal: Achieving Extremely Fine Powders

The number one reason to choose a ball mill is its effectiveness in producing very fine powders, often with particle sizes of 10 microns or less. For hard and abrasive materials, few other methods can achieve this level of fineness as reliably.

The Advantage: Versatility and Robustness

Ball mills are exceptionally versatile. They can be used for both wet and dry grinding and excel at processing very hard and abrasive source materials that would quickly destroy other types of mills.

The Safeguard: Contained and Sterile Processing

Because the process occurs within a sealed drum, ball mills are ideal for safely grinding toxic materials or for maintaining sterility. This is a critical feature in pharmaceutical manufacturing for products like parenteral drugs, where preventing outside contamination is paramount.

Making the Right Choice for Your Goal

To determine if a ball mill is appropriate, you must prioritize your project's most critical outcome.

- If your primary focus is product purity: A ball mill is a high-risk choice due to media contamination, unless you can invest in extremely hard, non-reactive media and accept higher maintenance costs.

- If your primary focus is cost-efficiency and throughput: The slow speed and high energy consumption make the ball mill a poor choice for high-volume, low-margin production.

- If your primary focus is achieving the finest possible particle size from a hard material: The ball mill is an excellent and often necessary tool, and its operational disadvantages are the accepted cost of achieving the desired result.

Ultimately, choosing a ball mill is a conscious decision to prioritize final particle size and material versatility over speed, energy efficiency, and absolute purity.

Summary Table:

| Disadvantage | Key Impact |

|---|---|

| High Energy Consumption | Significant operational costs due to inefficiency. |

| Risk of Media Contamination | Product purity compromised by worn grinding media. |

| Slow Grinding Process | Low throughput; time-consuming for fine powders. |

| Noise and Vibration | Workplace and environmental safety concerns. |

| Material Limitations | Ineffective for soft, fibrous, or heat-sensitive materials. |

Struggling with the trade-offs of ball mill grinding? There is a better way. At KINTEK, we specialize in laboratory equipment and consumables, offering advanced grinding solutions that prioritize efficiency, purity, and your specific material needs. Don't let high energy costs and contamination risks hold back your research or production. Contact our experts today to find the optimal grinding solution for your lab.

Visual Guide

Related Products

- Laboratory Single Horizontal Jar Mill

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

People Also Ask

- Why is it necessary to vacuum and introduce argon gas during ball milling? Protect Your Ti-Fe Composite Purity

- How do you increase ball mill efficiency? A Guide to Optimizing Grinding Performance

- What are the advantages of a planetary ball mill? Achieve ultrafine powders with speed and precision.

- What is the function of a planetary ball mill in composite electrode prep? Unlock 850 mAh/g Capacity

- Why are hardened steel grinding balls and jars selected for ODS ferritic steel? Maximize Alloying Efficiency & Purity

- How do you calculate ball mill residence time? Master Throughput and Product Fineness

- Why choose Zirconia (ZrO2) grinding media for Al6061/B4C composites? Optimize Purity and Dispersion

- What is the primary function of a ball mill and grinding media for SOFC slurries? Master Electrode Uniformity