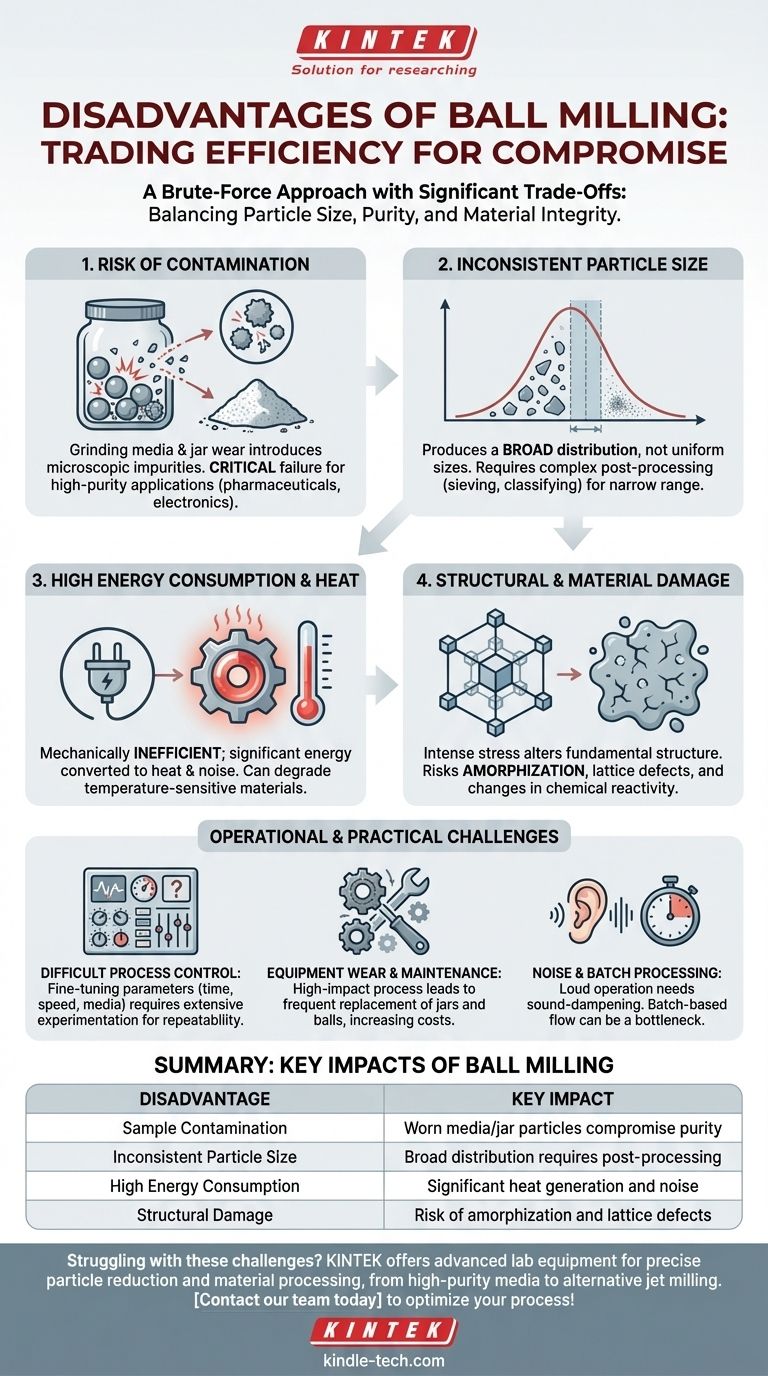

The primary disadvantages of ball milling are the potential for sample contamination, inconsistent final particle sizes, high energy consumption, and the risk of altering the material's fundamental properties through intense mechanical stress. This method, while widely used, is a brute-force approach with significant trade-offs.

The core challenge of ball milling is that its mechanism—smashing particles with heavy media—is inherently imprecise. This leads to a constant balancing act between achieving the desired particle size and accepting the collateral effects of contamination, energy waste, and potential damage to the material itself.

The Primary Drawbacks of the Ball Milling Process

Ball milling is a foundational technique for reducing particle size, but its effectiveness comes at a cost. The mechanical nature of the process introduces several key limitations that must be considered.

Risk of Contamination

The grinding process relies on the constant, high-impact collision between the grinding media (the balls) and the milling jar. Over time, both of these components inevitably wear down.

This wear introduces microscopic particles of the media and jar material directly into your sample. For high-purity applications, such as pharmaceuticals, electronics, or specialty chemicals, this contamination can be a critical failure point.

Inconsistent Particle Size Distribution

Ball milling does not produce uniformly sized particles. Instead, it creates a broad distribution of sizes, from very fine dust to larger, partially milled fragments.

Achieving a narrow, specific particle size range often requires additional post-processing steps, such as sieving or classifying. This adds complexity, time, and cost to the overall workflow.

High Energy Consumption and Heat

The process is mechanically inefficient. A significant portion of the electrical energy used to rotate the jar is converted into heat and noise, not particle breakage.

This generated heat can be detrimental to temperature-sensitive materials, potentially causing degradation, phase changes, or unwanted chemical reactions.

Potential for Structural Damage

The intense mechanical energy doesn't just reduce particle size; it can fundamentally alter the material's structure.

This can lead to amorphization (the loss of a crystalline structure), the introduction of lattice defects, and changes in the material's chemical reactivity. For applications in materials science where precise crystallographic properties are essential, this is a major disadvantage.

Understanding the Trade-offs and Operational Challenges

Beyond the direct impact on the material, there are practical and operational downsides to consider when implementing ball milling.

Difficult Process Control

Achieving perfectly repeatable results with ball milling is challenging. The final particle size is influenced by numerous variables, including milling time, speed, media size and quantity, and the material-to-media ratio. Fine-tuning these parameters requires extensive experimentation.

Equipment Wear and Maintenance

The abrasive and high-impact nature of the process leads to significant wear on the milling jar and balls. These components must be monitored and replaced regularly, contributing to ongoing operational costs and downtime.

Noise and Batch Processing

Ball mills are notoriously loud, often requiring dedicated rooms or sound-dampening enclosures. Furthermore, most lab- and production-scale setups are batch-based, which can be a bottleneck in workflows that would otherwise benefit from a continuous manufacturing process.

Making the Right Choice for Your Goal

To determine if ball milling is appropriate, you must weigh its disadvantages against the specific requirements of your project.

- If your primary focus is material purity: The risk of contamination is your biggest hurdle; you must use high-hardness, low-wear media (like zirconia) or consider an alternative, media-less method.

- If your primary focus is a precise, narrow particle size distribution: Ball milling may not be a one-step solution; plan for secondary classification steps or evaluate technologies like jet milling.

- If your primary focus is preserving the material's crystalline structure: The high mechanical energy is a significant threat; carefully control milling parameters or use a lower-energy milling technique.

- If your primary focus is simple, cost-effective bulk size reduction: Ball milling is often a viable workhorse, but you must account for energy consumption and maintenance in your total cost analysis.

Ultimately, understanding these inherent limitations is the key to using ball milling effectively or choosing a more suitable alternative.

Summary Table:

| Disadvantage | Key Impact |

|---|---|

| Sample Contamination | Worn media/jar particles compromise purity |

| Inconsistent Particle Size | Broad distribution requires post-processing |

| High Energy Consumption | Significant heat generation and noise |

| Structural Damage | Risk of amorphization and lattice defects |

| Difficult Process Control | Hard to fine-tune for repeatable results |

| Equipment Wear | High maintenance and replacement costs |

Struggling with contamination, inconsistent results, or material damage from ball milling? KINTEK specializes in advanced lab equipment and consumables, offering solutions for precise particle size reduction and material processing. Our experts can help you select the right technology—whether it's high-purity milling media or alternative methods like jet milling—to achieve your specific goals in pharmaceuticals, materials science, or specialty chemicals. Contact our team today to optimize your process and protect your materials!

Visual Guide

Related Products

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

People Also Ask

- What role do high-energy milling machines play in SiC mechanical alloying? Drive Nano-Scale Synthesis Efficiently

- What is the role of a V-type mixer in the preparation of Ti-Cr3C2 composite powders? Ensuring Macroscopic Uniformity

- What role do high-energy pulverizers play in API processing & how to manage contamination risks from wear parts?

- What are the advantages of a hammer mill? Versatile, Simple, and Precise Particle Size Control

- What is the mechanism of a grinding machine? Achieve Superior Precision and Surface Finishes

- Why is high-purity argon gas required during vibratory milling of Fe-Cr-Al alloys? Ensure Material Purity

- What are the advantages of using an agate mortar for manual mixing? Protect Particle Integrity in Solid-State Batteries

- Can zirconia be milled? Mastering the Green-State vs. Sintered Milling Process