While highly efficient for many industrial processes, roller mills are not a universal solution. Their primary disadvantages stem from their mechanical design, which makes them unsuitable for producing ultra-fine particles, handling very hard or abrasive materials, and processing feed that is sticky or has a high moisture content. Furthermore, the precision engineering involved often translates to a higher initial capital investment compared to simpler grinding technologies.

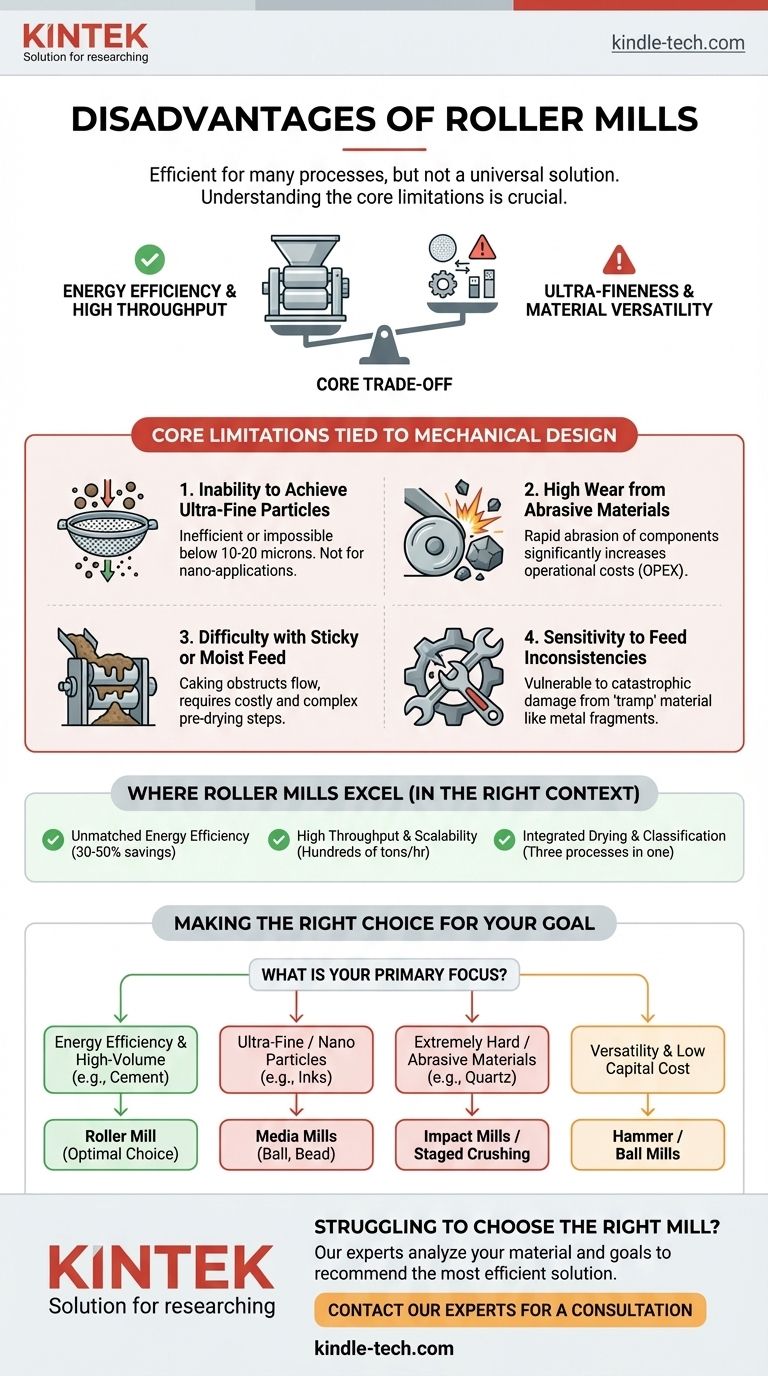

The core trade-off of a roller mill is exchanging ultimate particle fineness and material versatility for exceptional energy efficiency and high throughput. Its disadvantages become critical when your process requires sub-10-micron particles or involves grinding highly abrasive, wet, or sticky materials.

Core Limitations Tied to Mechanical Design

The disadvantages of a roller mill are directly linked to its grinding mechanism, which relies on compressing and shearing material between a rotating roller and a grinding ring or table.

Inability to Achieve Ultra-Fine Particles

A roller mill's grinding action is based on compressive force applied over a surface area. There is a physical limit to the minimum gap and the pressure that can be applied, which restricts the final particle size.

Achieving sizes below 10-20 microns becomes progressively inefficient and often impossible. For ultra-fine or nano-particle applications (e.g., high-performance coatings, pharmaceuticals), technologies like agitated media mills are necessary.

High Wear from Abrasive Materials

The direct, high-pressure contact between the rollers and the grinding ring makes the system highly susceptible to wear when processing hard or abrasive materials.

Substances with high silica content, such as certain ores or sands, can rapidly abrade these expensive components. This leads to frequent downtime for maintenance and significantly increases operational costs (OPEX), potentially negating the mill's energy efficiency benefits.

Difficulty with Sticky or Moist Feed

Roller mills require material to flow freely into the grinding zone and, in many designs, to be transported by an air stream for classification.

Sticky or high-moisture materials will cake onto the rollers and grinding table, obstructing the flow and severely reducing efficiency. This can lead to system clogs and complete operational stoppage, making pre-drying an essential and costly additional step.

Sensitivity to Feed Inconsistencies

The system is optimized for a specific feed size distribution. The introduction of oversized, unbreakable, or "tramp" material (like metal fragments) can cause catastrophic damage to the rollers and grinding track.

This necessitates robust upstream screening and magnetic separation processes to protect the investment, adding complexity and cost to the overall milling circuit.

Understanding the Trade-offs: Where Roller Mills Excel

To make an informed decision, you must weigh these disadvantages against the significant benefits roller mills offer in the right context.

Unmatched Energy Efficiency

For suitable materials like limestone, cement raw meal, or coal, roller mills are among the most energy-efficient grinding options available. The direct application of compressive force is far more efficient than the random impacts used in technologies like ball mills, often resulting in energy savings of 30-50%.

High Throughput and Scalability

Roller mills, particularly vertical roller mills (VRMs), are designed for massive throughput. They are the dominant technology in the cement industry for this reason, capable of processing hundreds of tons per hour in a single unit.

Integrated Drying and Classification

A key advantage of air-swept vertical roller mills is their ability to perform three processes in one machine: grinding, drying, and classifying. Hot process gas can be ducted through the mill to dry material as it's being ground, and an integrated classifier ensures only particles of the desired fineness exit the system.

Making the Right Choice for Your Milling Goal

Your ideal milling technology depends entirely on your final product specifications, raw material properties, and production scale.

- If your primary focus is energy efficiency and high-volume production (e.g., cement, phosphate rock): A roller mill is likely the optimal choice, provided the material is not excessively abrasive or moist.

- If your primary focus is achieving ultra-fine or nano-sized particles (e.g., inks, advanced ceramics): The fundamental limitations of a roller mill make it unsuitable; you must investigate media mills (ball, bead, or attritor mills).

- If your primary focus is grinding extremely hard or abrasive materials (e.g., quartz, fused alumina): The high wear rates on a roller mill may lead to prohibitive costs, making staged crushing or specialized impact mills more viable.

- If your primary focus is versatility with a low capital cost: The complexity and price of a roller mill are disadvantages; simpler technologies like hammer mills or ball mills might offer a better return on investment.

Understanding these core limitations allows you to select a milling circuit that is not just functional, but economically optimized for your specific goal.

Summary Table:

| Disadvantage | Key Limitation |

|---|---|

| Particle Size | Cannot efficiently grind below 10-20 microns |

| Abrasive Materials | High wear on rollers and grinding ring increases OPEX |

| Sticky/Moist Feed | Material caking and clogging can halt operations |

| Feed Sensitivity | Requires consistent feed size; vulnerable to tramp material |

| Capital Cost | Higher initial investment compared to simpler mills |

Struggling to Choose the Right Mill for Your Lab's Needs?

Every material is unique, and selecting the wrong milling technology can lead to inefficient processes, high operational costs, and failure to meet your product specifications. The disadvantages of a roller mill highlight the critical need for expert guidance.

KINTEK specializes in lab equipment and consumables, serving all your laboratory needs. We can help you navigate these trade-offs. Our experts will analyze your material properties—hardness, moisture content, and target particle size—to recommend the most efficient and cost-effective milling solution, whether it's a roller mill for high-throughput applications or an alternative like a ball or bead mill for ultra-fine grinding.

Don't let milling limitations hinder your research or production. Contact our experts today for a personalized consultation to optimize your milling process and achieve your goals.

Visual Guide

Related Products

- High Energy Planetary Ball Mill Machine for Laboratory Horizontal Tank Type

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Powerful Plastic Crusher Machine

- Mini Planetary Ball Mill Machine for Laboratory Milling

- Liquid Nitrogen Cryogenic Grinder Mill Cryomill Airflow Ultrafine Pulverizer

People Also Ask

- What is the function of a high-energy planetary ball mill in zirconium-doped CaO synthesis? Optimize Material Stability

- Why are high-intensity planetary ball mills preferred for reducing the crystallinity of lignocellulose?

- What is the role of a planetary ball mill in the preparation of NiCr-Al2O3-SrCO3 composite powders? Enhanced Homogeneity

- What role does a planetary ball mill play in SHS? Optimize Powder Activation for Superior Alloy Synthesis

- What is the specific role of a high-energy planetary ball mill in the synthesis of Ag-doped sulfide solid-state electrolytes?