The primary disadvantages of sieve analysis are its low resolution, its unsuitability for very fine or wet particles, and its time-consuming nature. Because a standard analysis uses a limited number of sieves, it generates only a few data points, creating a low-resolution picture of the particle size distribution. The physical limitations of the mesh also make it ineffective for particles smaller than approximately 50 micrometers.

Sieve analysis is a foundational and cost-effective technique, but its limitations in resolution and particle range make it unsuitable for applications requiring high-detail characterization of very fine, cohesive, or non-spherical particles.

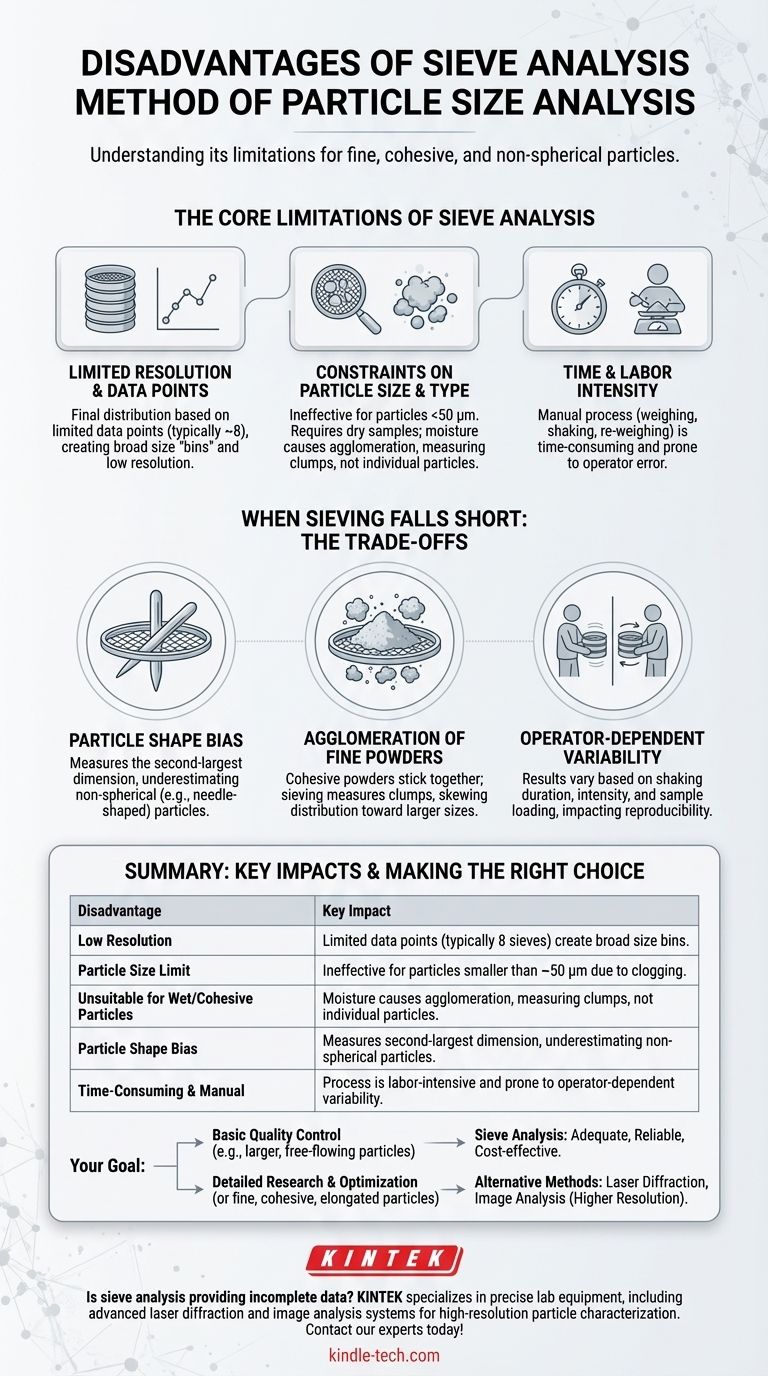

The Core Limitations of Sieve Analysis

While sieving is a trusted method for basic quality control, its inherent constraints can lead to incomplete or misleading results depending on the material and the required level of detail.

Limited Resolution and Data Points

A standard sieve stack typically consists of a maximum of eight sieves. This physical constraint means your final particle size distribution is based on just eight data points.

This creates broad size "bins" rather than a continuous distribution curve. You know how much material is between Sieve A and Sieve B, but you have no information on the distribution within that range.

Constraints on Particle Size and Type

Sieve analysis is not a universal solution. Its effectiveness is highly dependent on the physical properties of the particles themselves.

The practical lower limit for measurement is around 50 µm. Below this size, particles can easily clog the sieve mesh, and forces like static electricity can cause them to clump together, preventing accurate separation.

Furthermore, the method requires that the sample be completely dry. Any moisture will cause particles to agglomerate (stick together), meaning the sieve measures the size of clumps, not individual particles.

Time and Labor Intensity

The process of sieve analysis is manual and can be quite time-consuming. It involves weighing the sample, running the shaker for a set period, and then carefully weighing the material retained on each individual sieve.

This manual process not only takes time but also introduces the potential for operator error at multiple stages, from sample loading to final weighing.

Understanding the Trade-offs: When Sieving Falls Short

The fundamental principle of sieving—passing particles through a hole—creates specific challenges that can misrepresent the true nature of your material.

The Problem of Particle Shape

Sieve analysis measures a particle's second-largest dimension. An elongated or needle-shaped particle can pass through a sieve opening end-on, even if its length is much larger than the opening.

This means sieving can significantly underestimate the size of non-spherical particles, which is a critical issue in fields where particle shape influences performance.

Agglomeration of Fine Powders

Very fine powders are often cohesive, meaning they tend to stick together. Sieving may not provide enough energy to break these agglomerates apart.

As a result, you end up measuring the size of these clumps, leading to an inaccurate distribution skewed toward larger particle sizes.

Operator-Dependent Variability

Results can vary between different operators or even between tests run by the same operator. Factors like the duration of shaking, the intensity of the vibration, and the initial sample loading can all influence the final outcome. This can make it difficult to achieve high levels of reproducibility.

Making the Right Choice for Your Goal

Understanding these limitations is key to deciding if sieve analysis is the appropriate tool for your specific objective.

- If your primary focus is basic quality control or simple pass/fail checks: Sieve analysis is often a perfectly adequate, reliable, and cost-effective method for larger, free-flowing particles.

- If your primary focus is detailed research, development, or process optimization: The low resolution of sieving is a major drawback, and a higher-resolution technique like laser diffraction or image analysis is necessary.

- If your primary focus is analyzing fine, cohesive, or elongated particles: Sieve analysis is the wrong tool and will likely produce misleading data; alternative methods are required.

Ultimately, selecting the appropriate particle analysis method depends on a clear understanding of your material's properties and the specific data your application demands.

Summary Table:

| Disadvantage | Key Impact |

|---|---|

| Low Resolution | Limited data points (typically 8 sieves) create broad size bins. |

| Particle Size Limit | Ineffective for particles smaller than ~50 µm due to clogging. |

| Unsuitable for Wet/Cohesive Particles | Moisture causes agglomeration, measuring clumps, not individual particles. |

| Particle Shape Bias | Measures second-largest dimension, underestimating non-spherical particles. |

| Time-Consuming & Manual | Process is labor-intensive and prone to operator-dependent variability. |

Is sieve analysis providing incomplete data for your materials? For high-resolution characterization of fine, cohesive, or non-spherical particles, you need a more advanced solution. KINTEK specializes in precise lab equipment and consumables for all your particle analysis needs. Our experts can help you select the right technology—like laser diffraction or image analysis systems—to get the accurate, detailed data your research or quality control requires. Contact our team today to optimize your particle sizing workflow!

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Three-dimensional electromagnetic sieving instrument

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Wet Three-Dimensional Vibratory Sieve Shaker Machine

People Also Ask

- How do you calculate sieve mesh size? Use Official Standards for Accurate Particle Analysis

- Why is sieving equipment necessary for processing powder prior to hot extrusion of PEO? Ensure Cathode Film Uniformity

- Why must the crushing and sieving of Mg3Sb2 powder be conducted within an Argon atmosphere? Protect Material Integrity

- Is sieving a filtration method? Understanding the Critical Difference in Separation Processes

- How does size matter in the process of sieving? Master the Geometry of Particle Separation

- Why do we need sieve analysis? Ensure Material Quality and Performance with Particle Size Control

- Why is sieve analysis important? Ensure Consistent Quality and Performance of Your Materials

- What are the standard test sieves for ASTM? Ensure Accuracy with ASTM E11 Compliant Sieves