While sieve shakers are a cornerstone of particle analysis for many industries, their effectiveness is not universal. The primary disadvantages stem from fundamental physical limitations, including reduced accuracy for materials finer than 100 mesh, unreliable results for non-spherical particles, and the potential for altering or damaging the sample during testing. These issues become critical when high precision is required for very fine or irregularly shaped materials.

A sieve shaker's core limitation is its reliance on simple geometry and mechanical force. This makes it inherently unreliable for particles that are either too small to separate effectively or whose irregular shape allows them to pass through apertures that do not reflect their true size.

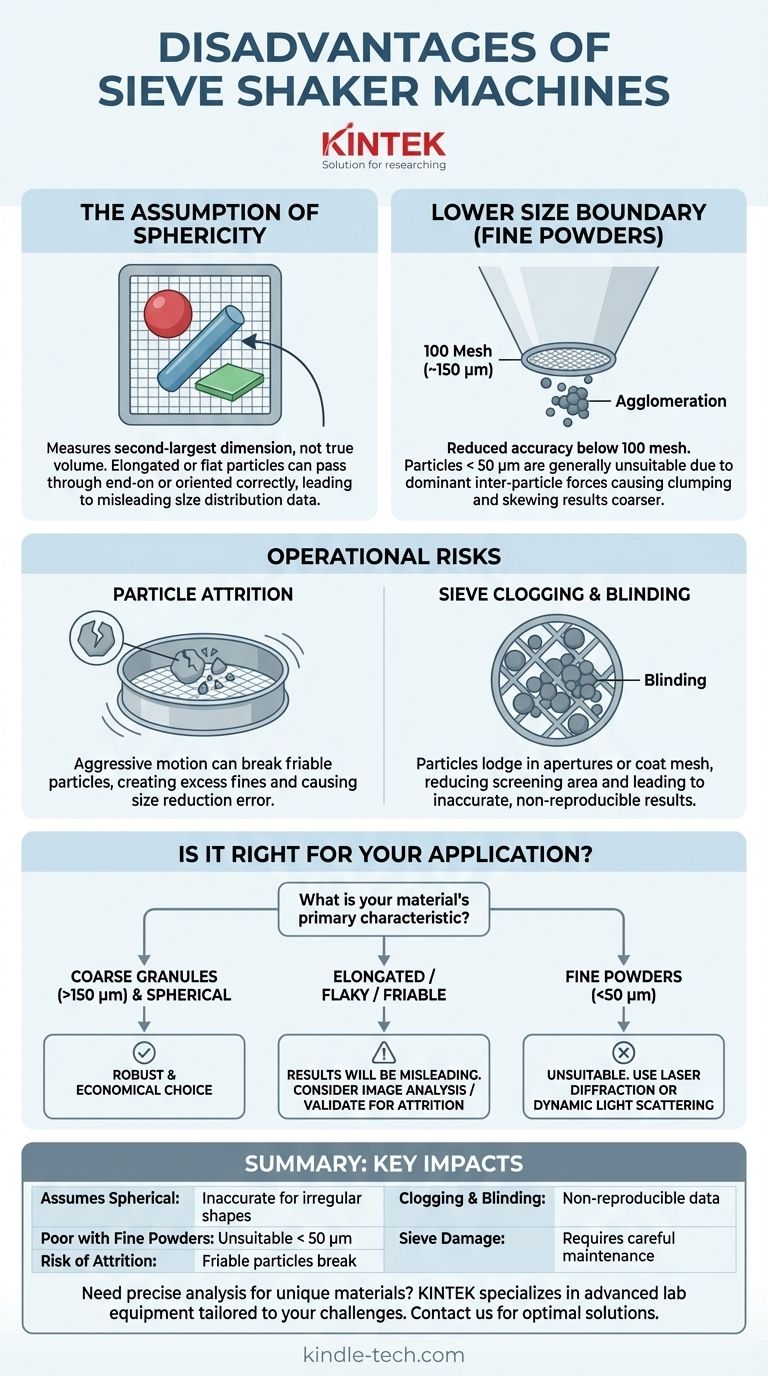

The Fundamental Limitation: The Assumption of Sphericity

A sieve shaker operates on a simple principle: particles smaller than the mesh openings fall through. However, this assumes all particles are perfect spheres, which is rarely true in practice.

Why Particle Shape Matters

A sieve analysis doesn't measure a particle's true diameter or volume. It measures a particle based on its second-largest dimension, as this is what determines if it can pass through a square mesh opening.

The Problem with Elongated and Flat Particles

Needle-like (acicular) or flaky (platy) particles create misleading results. A long, thin particle can pass through a sieve end-on, registering as much smaller than it actually is. Similarly, a flat particle can pass through if oriented correctly.

When Mass-Based Results Become Unreliable

Sieve analysis determines size distribution by weighing the material retained on each sieve. If elongated particles are present, the mass on a finer sieve may be artificially high, suggesting the sample is finer than it truly is. This fundamentally misrepresents the particle size distribution.

The Lower Size Boundary: Working with Fine Powders

Mechanical sieving becomes progressively less effective as particle size decreases. The forces governing particle interaction begin to outweigh the gravitational and mechanical forces of the shaker.

Reduced Accuracy Below 100 Mesh (~150 µm)

As particles become finer, forces like static electricity and moisture-induced cohesion cause them to agglomerate or stick together. These clumps behave like larger particles, preventing them from passing through the correct sieve and skewing the results toward a coarser distribution.

Unsuitability for Particles Under 50 µm

For particles smaller than approximately 50 micrometers (µm), mechanical sieving is generally considered unsuitable. At this scale, inter-particle forces are so dominant that it becomes nearly impossible to get them to pass through the mesh reliably. Other methods, such as laser diffraction, become necessary.

Understanding the Trade-offs and Operational Risks

Beyond these fundamental limitations, operational factors can introduce significant errors. These issues are often related to the sample itself or the maintenance of the equipment.

Risk of Particle Attrition

The aggressive shaking motion can cause attrition, where friable or brittle particles break down during the test. This creates more fine particles than were originally in the sample, leading to a "size reduction error" and an inaccurate final analysis.

Sieve Clogging and Blinding

Clogging occurs when particles become lodged in the sieve apertures, reducing the effective screening area. Blinding is a more severe version where a layer of fine particles coats the mesh surface, preventing any further material from passing through. Both lead to inaccurate and non-reproducible results.

Maintenance and Sieve Distortion

Sieves are precision instruments that can be damaged. Dropping a sieve or using improper cleaning methods can distort the frame or the mesh, altering the aperture size. A damaged sieve will consistently produce incorrect data and must be replaced.

Is a Sieve Shaker Right for Your Application?

Choosing the correct analysis method requires understanding these limitations in the context of your material and your goals.

- If your primary focus is cost-effective quality control of coarse granules (>150 µm): A sieve shaker is likely a robust, reliable, and economical choice.

- If you are working with elongated or flaky materials (e.g., fibers, minerals): Be aware that results will not reflect the true size; consider supplementing with image analysis if exact dimensions are critical.

- If your material is a fine powder with a significant portion under 50 µm: A sieve shaker is unsuitable, and you must investigate alternative methods like laser diffraction or dynamic light scattering.

- If your sample material is friable or easily broken: You must validate your method by checking for particle attrition to ensure your results are not being skewed by the testing process itself.

Ultimately, selecting the right tool for particle analysis depends on a clear understanding of your material's physical properties and the limitations of the method.

Summary Table:

| Disadvantage | Key Impact |

|---|---|

| Assumes Spherical Particles | Inaccurate results for elongated or flat particles. |

| Poor Performance with Fine Powders | Reduced accuracy below 100 mesh; unsuitable under 50 µm. |

| Risk of Sample Attrition | Friable particles can break, skewing results. |

| Sieve Clogging & Blinding | Can halt the test and produce non-reproducible data. |

| Sieve Damage & Distortion | Requires careful maintenance to ensure accuracy. |

Need precise particle analysis for your unique materials?

While sieve shakers have limitations, selecting the right equipment is crucial for reliable results. KINTEK specializes in providing advanced laboratory equipment and consumables tailored to your specific particle analysis challenges. Whether you're working with fine powders, irregular shapes, or friable materials, our experts can help you choose the optimal solution for accurate and reproducible data.

Contact us today to discuss your application and ensure your lab's efficiency and accuracy. Get in touch with our experts now!

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Laboratory Multifunctional Small Speed-Adjustable Horizontal Mechanical Shaker for Lab

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Vortex Mixer Orbital Shaker Multifunctional Rotation Oscillation Mixer

People Also Ask

- Why is a laboratory electromagnetic vibratory sieve shaker used? Optimize Walnut Shell Chemical Pretreatment

- How do high-precision sieving systems benefit zeolite preparation? Maximize Adsorption for Wastewater Treatment

- What are the disadvantages of sieve machine? Key Limitations in Particle Size Analysis

- Why is a precision vibratory sieving system important for Pt/Pd alloy analysis? Ensure Data Integrity & XRD Accuracy

- What is the significance of using a fine sieving system for catalyst particles? Optimize Size for Maximum Reactivity