While a foundational tool in materials analysis, the sieve shaker method has significant disadvantages, primarily rooted in its physical nature. Its accuracy diminishes sharply with fine powders, and it operates on a flawed assumption that all particles are perfect spheres, leading to unreliable results for materials with irregular shapes.

The core disadvantage of sieve shaking is its reliance on a mechanical process that cannot account for particle shape, static forces, or fragility. This makes it an inaccurate and often unsuitable method for analyzing fine powders, elongated particles, or materials where precise size distribution is critical.

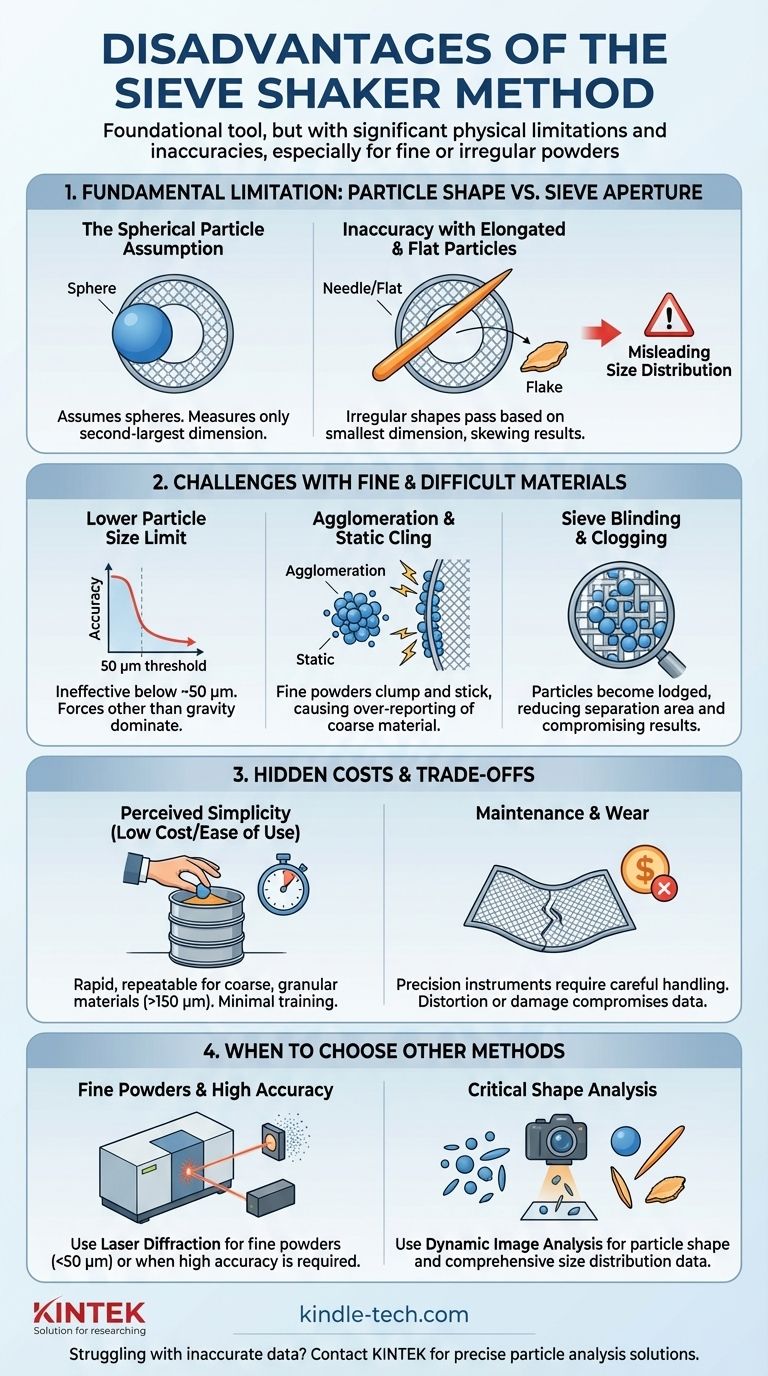

The Fundamental Limitation: Particle Shape vs. Sieve Aperture

The most significant source of error in sieve analysis comes from the interaction between a particle's geometry and the simple, two-dimensional opening of a sieve mesh.

The Spherical Particle Assumption

A sieve only measures a particle's second-largest dimension. The entire method implicitly assumes particles are spheres that will pass or be retained based on their diameter.

This assumption is rarely true in the real world. A long, needle-like particle can easily pass end-first through a sieve opening that is much smaller than its actual length.

Inaccuracy with Elongated and Flat Particles

For materials containing elongated, flat, or irregular particles, the mass-based results are misleading.

These non-spherical particles have a higher probability of passing through apertures that do not represent their true volume or mass, skewing the particle size distribution toward the finer end.

Particle Attrition and Size Reduction

The vigorous shaking motion can cause fragile or friable particles to break apart. This process, known as attrition, creates new, smaller particles during the test itself.

This artifact introduces a significant error, as you are no longer measuring the original sample but one that has been altered by the analysis method.

Challenges with Fine and Difficult Materials

Sieve shakers are notoriously problematic for powders and materials with specific physical properties that interfere with the sieving process.

The Lower Particle Size Limit

The effectiveness of sieving drops dramatically for particles smaller than approximately 50 micrometers (µm). Some sources note reduced accuracy even below 100 mesh (150 µm).

Below this threshold, forces other than gravity begin to dominate particle behavior, making simple mechanical separation unreliable.

Agglomeration and Static Cling

Fine powders are highly susceptible to agglomeration, where particles clump together due to moisture or intermolecular forces. They also generate static electricity, causing them to cling to each other and the sieve mesh.

These effects prevent individual particles from passing through the correct apertures, leading to an over-reporting of coarse material.

Sieve Blinding and Clogging

Sieve blinding occurs when particles become lodged in the mesh openings, effectively reducing the available area for separation.

This not only slows down the analysis but also prevents other particles from being correctly sorted, compromising the final result. It requires frequent, careful cleaning to mitigate.

Understanding the Trade-offs: Simplicity vs. Precision

Despite these drawbacks, the sieve shaker remains a common tool because its limitations are offset by practical advantages in specific contexts.

The Appeal: Low Cost and Ease of Use

The primary reason for its popularity is its simplicity and low cost compared to advanced methods like laser diffraction. For many routine quality control applications on coarse materials, it is "good enough."

It offers rapid, repeatable results and requires minimal operator training, making it an efficient choice for production environments.

The Hidden Costs: Maintenance and Wear

The perceived low cost can be misleading. Sieves are precision instruments that can be damaged by improper handling or cleaning.

Distortion of the frame or damage to the mesh compromises accuracy, requiring regular inspection and costly replacement to ensure reliable data.

When to Choose Other Methods

For applications involving fine powders, critical shape analysis, or the need for high-resolution distribution data, sieve shaking is the wrong tool.

Methods like laser diffraction (for fine powders) and dynamic image analysis (for shape and size) provide far more accurate and comprehensive data where the sieve shaker's assumptions break down.

Making the Right Choice for Your Analysis

Select your particle analysis method based on your material's properties and the data you truly need.

- If your primary focus is routine quality control for coarse, granular materials (>150 µm): The sieve shaker is often a reliable and cost-effective method.

- If you are working with fine powders (<50 µm) or require high accuracy: You must account for issues like agglomeration and strongly consider an alternative method like laser diffraction.

- If particle shape is a critical parameter for your process or material performance: Sieve analysis will provide misleading data, and you should use a method like dynamic image analysis.

By understanding these limitations, you can correctly determine when a sieve shaker is a practical tool versus when a more advanced analysis technique is required.

Summary Table:

| Disadvantage | Key Impact |

|---|---|

| Assumes Spherical Particles | Inaccurate results for elongated or flat materials |

| Particle Attrition | Fragile particles break, altering the sample |

| Ineffective on Fine Powders | Poor accuracy below ~50 µm due to static and agglomeration |

| Sieve Blinding & Clogging | Slows analysis and prevents accurate separation |

| Limited Resolution | Provides less detail than laser diffraction or image analysis |

Struggling with inaccurate particle size data? The limitations of a sieve shaker can directly impact your product quality and process efficiency. For fine powders, fragile materials, or when particle shape is critical, you need a more advanced solution. KINTEK specializes in precise lab equipment, including laser diffraction analyzers and dynamic image analysis systems, to deliver the accurate, comprehensive data your laboratory requires. Contact our experts today to find the right particle analysis solution for your specific needs!

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Three-dimensional electromagnetic sieving instrument

- Laboratory Multifunctional Small Speed-Adjustable Horizontal Mechanical Shaker for Lab

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Vibratory Sieve Shaker Machine Dry Three-Dimensional Vibrating Sieve

People Also Ask

- Why is a laboratory sieving system required for bentonite in coatings? Ensure Flawless Surface Performance

- What is the necessity of using a Constant Temperature Shaker in enzymatic hydrolysis? Unlock High Paper Pulp Yields

- Why are crushing and sieving systems indispensable prior to the recovery of platinum? Maximize Your Extraction Yield

- What is the purpose of using a sieve shaker in sieve analysis? Achieve Accurate Particle Size Data

- What is the amplitude of a sieve shaker? A Guide to Optimizing Particle Separation

- Why is a benchtop shaker essential during the biosorption experiments of palladium ions (Pd2+)? Maximize Your Ion Yield

- What is a shaking machine for wet sieving? Achieve Accurate Particle Size Analysis for Fine Powders

- Why is a standard laboratory sieving system required for anisotropic graphite flake composites? Ensure Peak Precision.