While sieving is a foundational technique for particle separation, its primary disadvantages are its ineffectiveness with very fine or elongated particles, the potential for damaging fragile materials, and operational issues like mesh clogging. The process is also significantly slower and less precise than modern methods like laser diffraction, making it unsuitable for high-resolution analysis.

Sieving is simple and intuitive, but this simplicity comes at a cost. Its effectiveness is fundamentally limited by the physical properties of the particles themselves, leading to inaccuracies and operational challenges that more advanced techniques are designed to overcome.

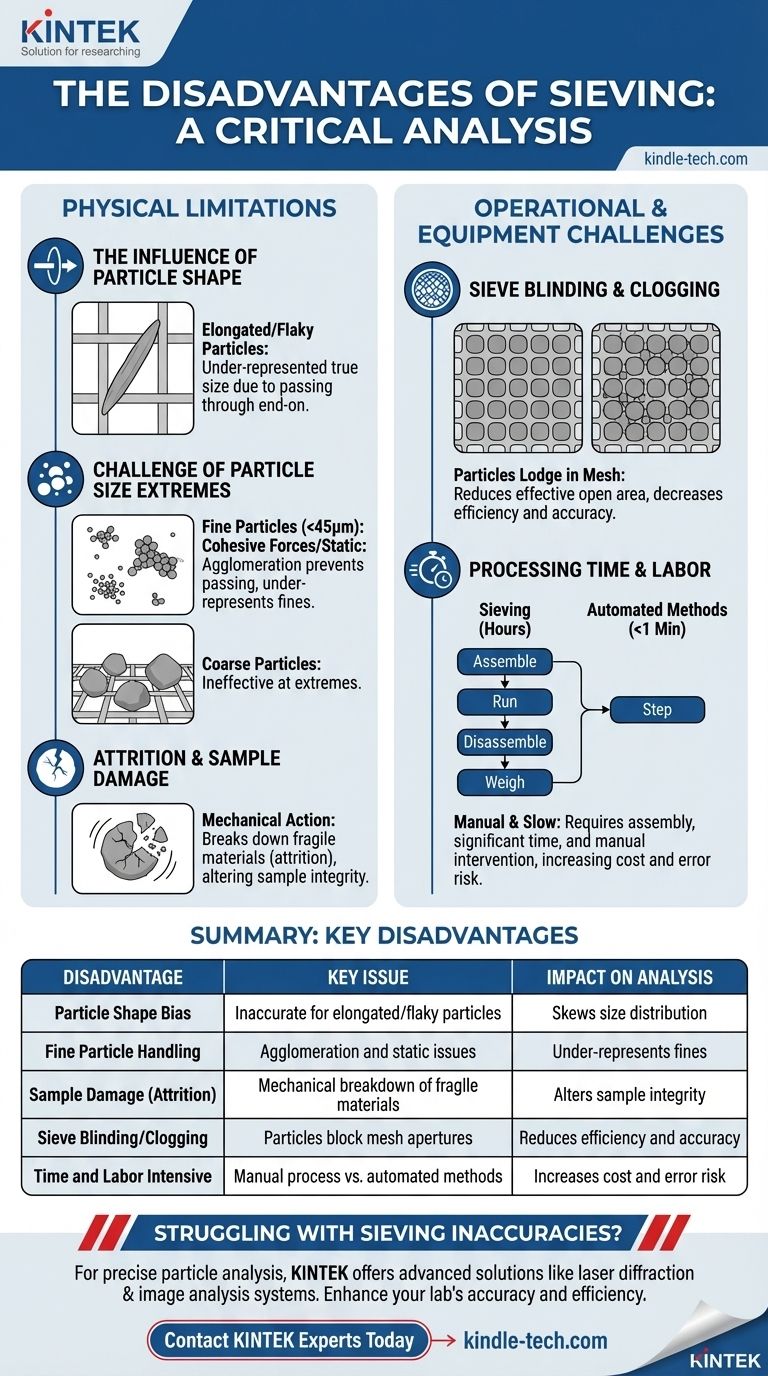

The Physical Limitations of the Method

Sieving relies on a simple mechanical principle, but the physical nature of particles can easily disrupt this process, leading to inaccurate results.

The Influence of Particle Shape

A sieve only measures a particle's second-largest dimension. Elongated or flaky particles can pass through mesh openings end-on or sideways, even if their largest dimension (e.g., length) is much bigger than the aperture.

This means sieving can systematically under-represent the true size of non-spherical particles, leading to a skewed particle size distribution.

The Challenge of Particle Size Extremes

Sieving struggles at both the very fine and very coarse ends of the spectrum. For particles smaller than approximately 45 microns, physical forces begin to dominate gravity.

Cohesive forces and static electricity can cause fine particles to clump together (agglomerate), preventing them from passing through the mesh. This results in a measurement that incorrectly shows fewer fine particles than are actually present.

Attrition and Sample Damage

The mechanical action of sieving—shaking, vibrating, or tapping—can damage the material being analyzed. This process, known as attrition, breaks down brittle or friable particles into smaller pieces.

This is a critical flaw when analyzing materials where particle integrity is essential, such as in pharmaceuticals or certain food products. The act of measurement fundamentally alters the sample.

Operational and Equipment Challenges

Beyond the physics of the particles, the sieving process itself presents several practical difficulties that can compromise results and efficiency.

Sieve Blinding and Clogging

Blinding occurs when particles become lodged in the sieve apertures, effectively blocking the mesh. This is especially common with particles that are very close in size to the mesh openings.

As the sieve becomes blinded, its effective open area decreases, drastically reducing its efficiency and leading to an incomplete separation of the sample.

Processing Time and Labor

Achieving an accurate and complete separation through sieving can be a very time-consuming process. For analytical purposes, sieve stacks must be assembled, run for a specific duration, disassembled, and each fraction must be carefully weighed.

Compared to automated techniques that can produce a result in under a minute, a full sieve analysis can take hours and requires significant manual intervention, increasing labor costs and the potential for human error.

Understanding the Core Trade-off: Simplicity vs. Precision

The choice to use sieving hinges on a critical trade-off. You are exchanging the high precision and resolution of modern methods for the simplicity and low capital cost of sieves.

Sieving is an excellent, cost-effective tool for routine quality control of coarse, free-flowing, and robust granular materials where high-resolution data is not required. It gives a good-enough answer quickly.

However, when working with fine powders, materials with mixed shapes, or when a detailed particle size distribution is critical for product performance, the inaccuracies and limitations of sieving become a significant liability. Methods like laser diffraction or image analysis provide far superior data in these cases.

Making the Right Choice for Your Goal

To select the right approach, you must first define your objective.

- If your primary focus is routine quality control for coarse materials (e.g., sand, grain, plastic pellets): Sieving is likely an effective and economical choice due to its simplicity and robustness.

- If your primary focus is high-resolution analysis of fine powders (e.g., pharmaceuticals, pigments, metal powders): Sieving is the wrong tool; you should use laser diffraction or dynamic light scattering to overcome issues of agglomeration and achieve accurate results.

- If your primary focus is analyzing fragile or elongated particles (e.g., crystals, fibers): Sieving is risky due to attrition and shape bias; consider static image analysis, which can measure particle length and shape without destroying the sample.

Understanding these inherent limitations is the first step toward accurate and reliable particle separation.

Summary Table:

| Disadvantage | Key Issue | Impact on Analysis |

|---|---|---|

| Particle Shape Bias | Inaccurate for elongated/flaky particles | Skews size distribution |

| Fine Particle Handling | Agglomeration and static issues | Under-represents fines |

| Sample Damage (Attrition) | Mechanical breakdown of fragile materials | Alters sample integrity |

| Sieve Blinding/Clogging | Particles block mesh apertures | Reduces efficiency and accuracy |

| Time and Labor Intensive | Manual process vs. automated methods | Increases cost and error risk |

Struggling with sieving inaccuracies? For precise particle analysis of fine powders, fragile materials, or complex shapes, KINTEK provides advanced lab equipment solutions like laser diffraction and image analysis systems. Enhance your lab's accuracy and efficiency—contact our experts today to find the right tool for your needs!

Visual Guide

Related Products

- Laboratory Test Sieves and Sieving Machines

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Single Horizontal Jar Mill

- High Energy Vibratory Laboratory Ball Mill Grinding Mill Single Tank Type

- High Energy Planetary Ball Mill Machine for Laboratory Horizontal Tank Type

People Also Ask

- What are the specifications for test sieves? A Guide to ASTM & ISO Standards for Accurate Particle Analysis

- Why is a precision vibrating sieve shaker essential for metal leaching research? Optimize Your Particle Size Analysis

- What is the primary purpose of using standard sieves? Master Particle Uniformity for High-Quality Catalyst Preparation

- Why is sieve analysis important? Ensure Consistent Quality and Performance of Your Materials

- How is a vibratory sieve shaker used in the particle size analysis of mechanically alloyed powders? Expert Guide