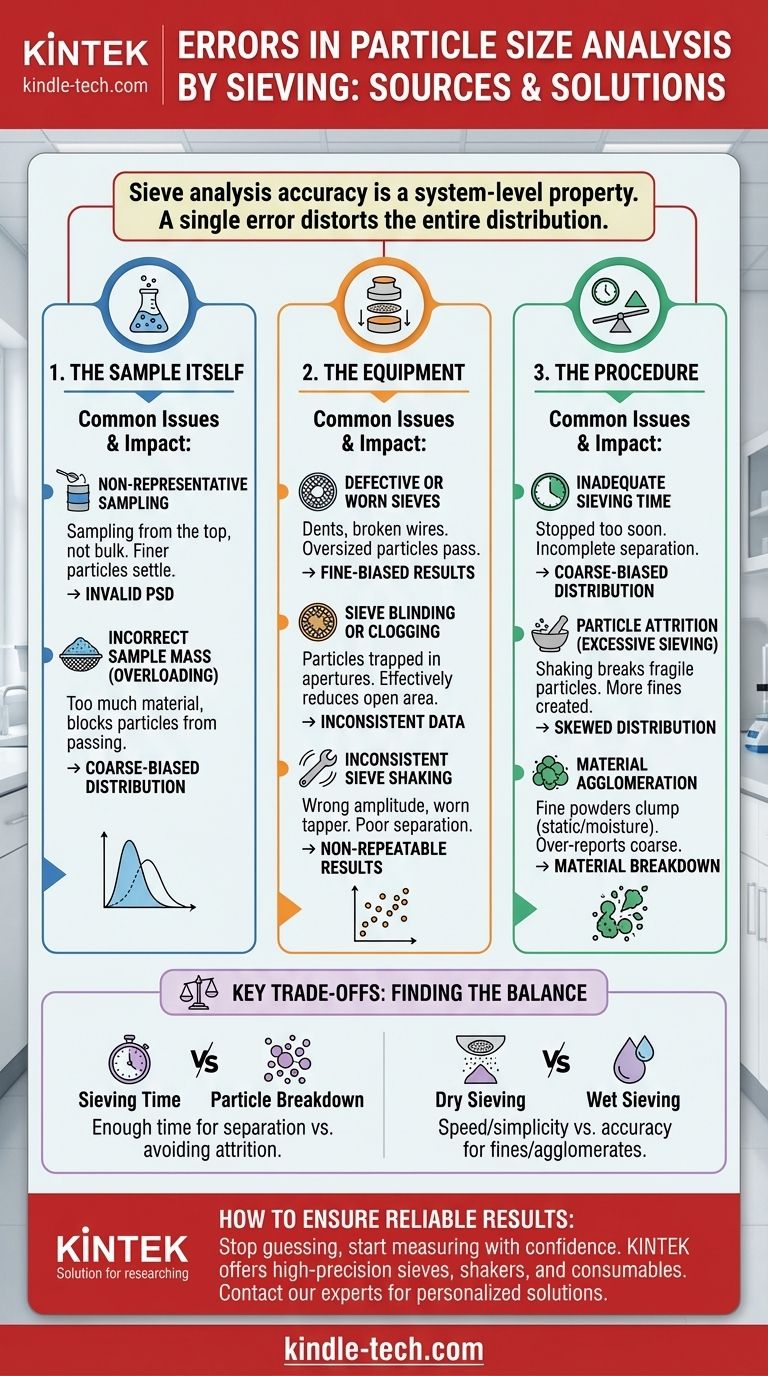

The primary errors in particle size analysis by sieving stem from three main sources: the sample itself being non-representative or too large, the equipment being worn or uncalibrated, and the operational procedure being inconsistent. Issues like damaged sieve mesh, overloading the sieves with material, and sieving for too little or too much time are the most common culprits that can render results unreliable.

Sieve analysis appears simple, but its accuracy is a system-level property. Achieving trustworthy results is not about perfecting a single step, but about rigorously controlling every variable from the initial sample extraction to the final weighing.

Why Small Errors Have a Big Impact

Sieve analysis is a method of fractions. Each sieve separates particles, and the final result—the Particle Size Distribution (PSD)—is a cumulative calculation based on the weight of material retained on each screen.

An error at any single stage does not stay isolated. For example, if the top sieve is overloaded, it creates a bottleneck. This artificially increases the weight on that sieve and starves all subsequent sieves of material, skewing the entire distribution curve and leading to incorrect conclusions about product quality or process efficiency.

Error Source 1: The Sample Itself

The analysis is invalid before it even begins if the sample is not a true representation of the bulk material.

Non-Representative Sampling

The material used for the test (typically 50-100g) must have the same particle size distribution as the entire production batch (which could be tons). Grabbing a scoop from the top of a drum is not sufficient, as finer particles tend to settle.

Proper techniques like coning and quartering or using a rotary sample divider (spinner riffler) are essential to obtain a small, statistically representative sample.

Incorrect Sample Mass (Overloading)

This is arguably the most common procedural error. If you put too much material onto a sieve, the layer of particles is too thick. This prevents many smaller particles from ever reaching the mesh surface to pass through.

This leads to an artificially high weight on coarser sieves and an incorrect result, often called a "coarse-biased" distribution. The rule of thumb is that the depth of material on any sieve should not exceed a few particle diameters.

Error Source 2: The Equipment

The condition of your sieves and shaker is non-negotiable. Worn-out tools produce worthless data.

Defective or Worn Sieves

Sieve mesh is fragile. Dents, sagging, or broken wires create larger, inconsistent openings that allow oversized particles to pass through, biasing the results toward the "finer" end.

Regularly inspect sieves visually under magnification. For critical applications, sieves should be periodically recertified using calibration beads or image analysis to ensure the apertures meet ASTM or ISO standards.

Sieve Blinding or Clogging

Blinding occurs when particles become lodged in the sieve apertures and are not dislodged during shaking. This effectively reduces the open area of the sieve, preventing other, smaller particles from passing through.

This is common with near-size particles or materials with high moisture content. It results in an artificially high weight retained on the blinded sieve.

Inconsistent Sieve Shaking

The sieve shaker's job is to distribute the material over the mesh and provide energy to help particles pass through. An inconsistent motion (e.g., wrong amplitude, worn-out tapper) will not produce repeatable results.

The motion must be validated. A good shaker combines a horizontal, circular motion with a vertical tapping motion to keep particles moving and clear the apertures.

Error Source 3: The Procedure

Even with a perfect sample and perfect equipment, the operator's technique can introduce significant variability.

Inadequate Sieving Time

Every material needs a specific amount of time for complete separation. If the test is stopped too soon, many particles will not have had the chance to pass through the appropriate sieves.

This results in a coarse-biased distribution. The operator must perform an "end-point determination" test to find the minimum time required for a stable result (i.e., when less than 0.1% of the material on a sieve passes through after an additional minute of sieving).

Particle Attrition (Excessive Sieving)

The opposite problem is sieving for too long. The mechanical action of the shaker can cause fragile particles to break down or wear away (attrition).

This breakdown creates more fine particles than were present in the original sample, skewing the distribution toward the "finer" end. This is a critical concern for friable materials.

Material Agglomeration

Fine powders, especially those under 75 microns, can clump together due to electrostatic forces or moisture. These agglomerates behave like single large particles, preventing them from passing through the correct fine mesh.

This leads to a significant over-reporting of coarse particle fractions. Using an anti-static agent or switching to a wet sieving method is the correct solution.

Material Loss and Weighing Errors

Small errors in weighing can have a large impact, especially on sieves that retain little material. Losing powder during transfer from the sieve to the balance is a common source of error.

The total weight of all the separated fractions plus the pan should equal the initial sample weight. A deviation of more than 0.5% typically indicates a procedural error, such as material loss or a weighing mistake.

Understanding the Key Trade-offs

Making the right choices requires understanding the inherent compromises in the method.

Sieving Time vs. Particle Breakdown

You need enough time to ensure complete separation, but too much time can destroy your particles. The goal is to find the "sweet spot" through validation, where separation is maximized just before attrition becomes a significant factor.

Dry Sieving vs. Wet Sieving

Dry sieving is faster and simpler. However, for fine powders (<45 microns) or materials that agglomerate, it is often inaccurate. Wet sieving eliminates static and washes particles through apertures, but it adds complexity, requires careful drying, and introduces more steps where errors can occur.

Sample Size vs. Sieve Overloading

A larger starting sample is often more representative of the bulk material. However, it dramatically increases the risk of overloading the top sieves. It is always better to start with a larger representative sample and use a sample splitter to create a smaller, manageable test specimen.

How to Ensure Reliable Results

Your approach should be dictated by your ultimate goal for the data.

- If your primary focus is Routine Quality Control: Standardize every step in a detailed Standard Operating Procedure (SOP) and ensure all operators are trained to follow it precisely.

- If your primary focus is Method Development or R&D: Validate every parameter, especially sieving time and sample load, and use certified, calibrated sieves to ensure absolute accuracy.

- If your primary focus is Troubleshooting Inconsistent Data: Systematically investigate the most common and impactful errors first—sieve condition (damage/blinding) and sample overloading.

Ultimately, mastering sieve analysis comes from treating it as a controlled scientific process, not just a simple shaking procedure.

Summary Table:

| Error Category | Common Issues | Impact on Results |

|---|---|---|

| Sample | Non-representative sampling, overloading | Coarse-biased distribution, invalid PSD |

| Equipment | Worn/damaged sieves, inconsistent shaker | Fine-biased results, non-repeatable data |

| Procedure | Incorrect sieving time, agglomeration, attrition | Skewed distribution, material breakdown |

Stop guessing and start measuring with confidence. KINTEK specializes in high-precision lab sieves, shakers, and consumables designed to eliminate the common errors outlined above. Our equipment ensures accurate, repeatable particle size analysis for quality control, R&D, and troubleshooting.

Contact our experts today to discuss your specific application and receive a personalized recommendation to enhance your lab's efficiency and data reliability.

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Three-dimensional electromagnetic sieving instrument

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Wet Three-Dimensional Vibratory Sieve Shaker Machine

People Also Ask

- What is sieving used for in science? A Guide to Particle Size Analysis & Control

- What are the factors affecting sieving performance and efficiency? Optimize Your Particle Separation Process

- What is sieve analysis in construction? Ensure Material Quality & Project Success

- How to choose sieve size? Build the Perfect Sieve Stack for Accurate Particle Analysis

- What can be separated by sieving? A Guide to Particle Size Separation for Various Materials

- What is the purpose of using a laboratory grinder with specific mesh sieves for oat straw? Optimize Pellet Quality

- What is the process of sieve separation? A Guide to Precise Particle Size Analysis

- What is the function of a standard test sieve in magnesium recovery? Optimize Slag Enrichment and Process Efficiency