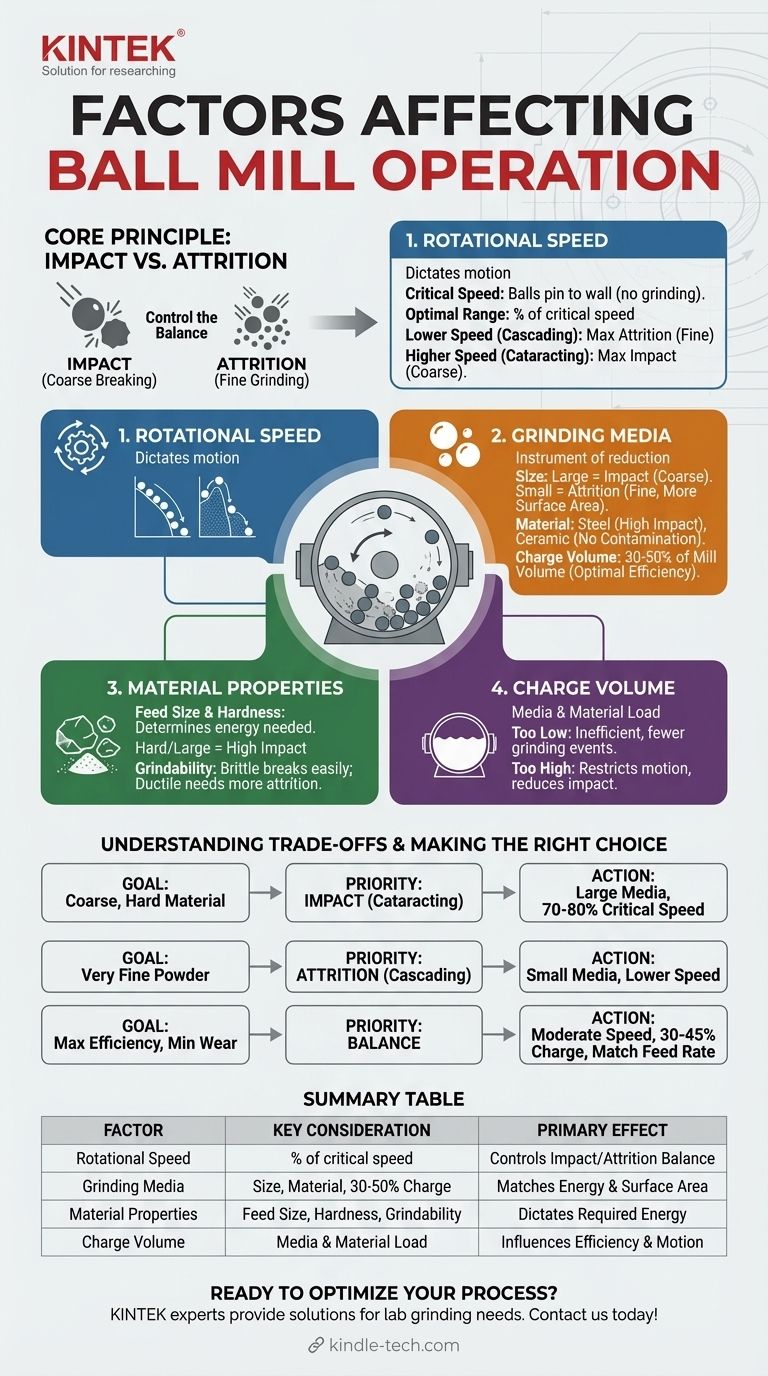

To be direct, four primary factors govern the performance of a ball mill: the speed of its rotation, the characteristics of the grinding media (the balls), the properties of the material being ground, and the volume of media and material inside the mill. Mastering the interplay between these variables is the key to achieving a consistent and desired particle size efficiently.

The core challenge in ball mill operation is not simply to grind, but to control the type of grinding. Every adjustment to speed, media, or load is a deliberate choice between two fundamental forces: impact for coarse breaking and attrition for fine grinding.

The Core Principle: Impact vs. Attrition

Before adjusting any setting, it is essential to understand the two mechanisms a ball mill uses to reduce particle size. All operational factors are simply levers to control the balance between them.

Impact Grinding

Impact is the forceful collision that occurs when grinding balls are lifted by the rotating mill shell and fall onto the material below. This action is powerful and is the primary force responsible for breaking down large, coarse feed particles.

Attrition Grinding

Attrition is the shearing and rubbing action that occurs as balls cascade over one another. This creates immense pressure and friction between the balls, grinding the material trapped between them into very fine particles.

Optimizing Rotational Speed

The speed of the mill is arguably the most critical operational factor because it directly dictates the motion of the grinding media.

Understanding Critical Speed

Critical speed is the theoretical rotational speed at which the centrifugal force pins the grinding balls to the inner wall of the mill. At or above this speed, the balls no longer tumble, and grinding stops completely.

The Optimal Speed Range

Effective grinding occurs at a specific percentage of the critical speed. Operating well below the critical speed causes the balls to merely slide or "cascade," which maximizes attrition but provides little impact. As speed increases, the balls are lifted higher before falling, creating a "cataracting" motion that maximizes impact.

Selecting the Right Grinding Media

The balls inside the mill are the instruments of size reduction. Their size, material, and quantity are fundamental to the process.

Media Size

The size of the grinding media must be matched to the feed material. Large balls are necessary to create the high-impact energy needed to fracture coarse particles. Small balls, however, have a much greater total surface area and create more contact points, making them ideal for the fine grinding associated with attrition.

Media Material

Balls are typically made from materials like high-carbon steel, stainless steel, or ceramic. The choice depends on the application. Steel offers high density and impact force, while ceramic is used when product contamination from metal is a concern.

Media Charge Volume (Filling Ratio)

The volume of the mill occupied by the balls, known as the charge or filling ratio, is critical. This is typically between 30% and 50% of the mill's internal volume. Too low a charge reduces the number of grinding events and is inefficient. Too high a charge restricts the motion of the balls, muffling their impact and reducing overall efficiency.

Accounting for Material Properties

The material you intend to grind is not a passive element; its own characteristics dictate the operational parameters required.

Feed Size and Hardness

The size and hardness of the feed material determine the energy required for breakage. Hard, large particles demand larger media and a speed that favors high-impact cataracting motion.

Material Grindability

Different materials fracture in different ways. Brittle materials break easily under impact, while more ductile materials may require more attritional grinding over a longer period.

Understanding the Trade-offs

Optimizing a ball mill is always a matter of balancing competing factors. There is no single "best" setting, only the best setting for a specific goal.

Speed vs. Wear

Increasing rotational speed can increase throughput, but it also dramatically accelerates the wear rate on both the grinding media and the mill's internal liners. This increases operational costs and downtime.

Media Size vs. Final Particle Size

Using large media is effective for initial size reduction but is highly inefficient at producing ultra-fine particles. Achieving a very fine end-product often requires smaller media, which may struggle to break the initial coarse feed.

Throughput vs. Efficiency

Attempting to push material through the mill too quickly will reduce its residence time. This results in insufficient grinding, leading to a coarser final product and wasted energy.

Making the Right Choice for Your Goal

You must adjust the operational factors to match your desired outcome.

- If your primary focus is breaking down coarse, hard material: Prioritize impact forces by using larger grinding media and operating at a speed (e.g., 70-80% of critical) that promotes a cataracting motion.

- If your primary focus is producing a very fine powder: Prioritize attrition by using smaller media to maximize surface area and operating at a lower speed to encourage a cascading, rubbing motion.

- If your primary focus is maximizing efficiency and minimizing wear: Operate at a moderate speed, ensure the media charge is between 30-45%, and precisely match the material feed rate to the mill's grinding capacity.

By understanding these core factors, you transform ball milling from a brute-force process into a precise and controllable engineering task.

Summary Table:

| Factor | Key Consideration | Primary Effect on Grinding |

|---|---|---|

| Rotational Speed | Percentage of critical speed | Controls balance between impact (coarse) and attrition (fine) |

| Grinding Media | Size, material, and filling ratio (30-50%) | Matches energy and surface area to feed size and hardness |

| Material Properties | Feed size, hardness, and grindability | Dictates required energy and grinding mechanism |

| Charge Volume | Media and material load inside the mill | Influences grinding efficiency and media motion |

Ready to Optimize Your Ball Milling Process?

Achieving the perfect balance between impact and attrition is key to efficient particle size reduction. The experts at KINTEK specialize in lab equipment and consumables, providing the right solutions for your laboratory's grinding needs. Whether you're processing coarse, hard materials or aiming for ultra-fine powders, we can help you select and optimize the right equipment for maximum efficiency and minimal wear.

Contact KINTEK today to discuss your specific application and let our expertise enhance your lab's performance!

Visual Guide

Related Products

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Laboratory Single Horizontal Jar Mill

- Laboratory Four-Body Horizontal Jar Mill

- Laboratory Horizontal Planetary Ball Mill Milling Machine

People Also Ask

- What is the purpose of the wet ball milling process? Optimize Li8/7Ti2/7V4/7O2 Cathode Synthesis Quality

- How does the ball mill work? Master the Mechanics of Efficient Grinding and Size Reduction

- What is the role of a high-energy planetary ball mill in W-Cu powder preparation? Achieve Superior Material Uniformity

- How do you calculate ball mill load? Optimize Grinding Efficiency and Reduce Costs

- What role does a planetary ball mill play in the preparation of aluminum-based crucible slurry? Expert Homogenization

- What role does a planetary ball mill play in the preparation of Fe3Si? Mastering Atomic Mixing for Phase Purity

- What function does mechanical alloying equipment perform? Optimize Self-Passivating Tungsten Alloy Powder Preparation

- What are the application of ball mill in food industry? Achieve Ultra-Fine Grinding for Superior Food Quality