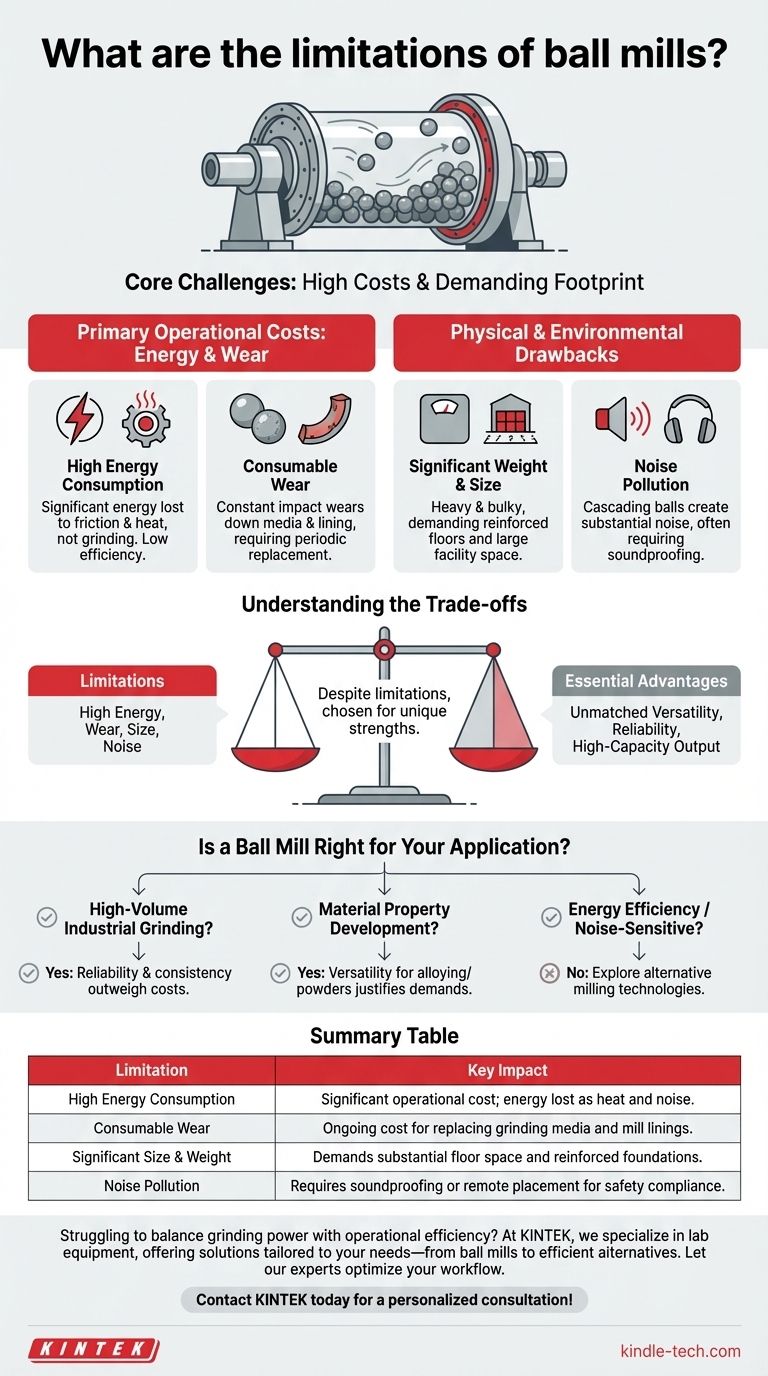

While highly effective and versatile, a ball mill's primary limitations are its significant operational costs and demanding physical footprint. They are characterized by high energy consumption, considerable noise output, and substantial weight, which are fundamental trade-offs for their robust grinding capabilities.

The core challenge of a ball mill is not its effectiveness but its efficiency. Its limitations in energy consumption, noise, and physical size must be weighed against its exceptional reliability, versatility, and capacity for large-scale material processing.

The Primary Operational Costs: Energy and Wear

A ball mill's simple, brute-force mechanism is reliable but inherently inefficient. Understanding these operational costs is critical for assessing its long-term viability for any project.

High Energy Consumption

The grinding action generates significant friction and heat. A large portion of the electrical energy consumed by a ball mill is lost to this friction, heating the material, and producing noise, rather than being used for particle size reduction.

Consumable Wear

The constant impact and abrasion wear down both the grinding media (the balls) and the internal lining of the mill chamber. This wear is a direct operational cost, as these components must be periodically replaced to maintain consistent performance.

Physical and Environmental Drawbacks

Beyond operational costs, the physical nature of ball mills presents logistical and environmental challenges that must be planned for.

Significant Weight and Size

Ball mills are exceptionally heavy and bulky machines. This "unhandiness" impacts facility requirements, demanding reinforced foundations and significant floor space for both the mill and its associated material handling equipment.

Noise Pollution

The cascading and impact of the steel balls against the material and chamber wall create substantial noise. This often requires dedicated soundproof enclosures or situating the mill away from personnel to comply with workplace safety regulations.

Understanding the Trade-offs: Why Ball Mills Remain Essential

Despite these clear limitations, the ball mill remains a cornerstone of industrial processing. Its drawbacks are often accepted because its advantages are difficult to replicate.

Unmatched Versatility

Ball mills can process an incredibly wide range of materials, from hard mining ores and coal to chemical pigments and feldspar. They are also used for advanced applications like mechanical alloying, producing amorphous materials, and safely blending explosives.

Reliability and Simplicity

The design of a ball mill is fundamentally simple, leading to high operational reliability and straightforward servicing. There are few complex parts to fail, making it a trusted workhorse in continuous production environments.

Consistent, High-Capacity Output

Once configured, a ball mill provides a very consistent milling fineness over long periods. Its high capacity makes it ideal for large-scale industrial grinding where consistent output is paramount.

Is a Ball Mill Right for Your Application?

Choosing a ball mill requires aligning your primary goal with the machine's inherent strengths and weaknesses.

- If your primary focus is high-volume industrial grinding: The reliability, high capacity, and output consistency of a ball mill will likely outweigh the high energy and maintenance costs.

- If your primary focus is material property development: For applications like mechanical alloying or creating specific powders, the ball mill's versatility is a key advantage that justifies its operational demands, especially at a laboratory scale.

- If your primary focus is energy efficiency or a noise-sensitive environment: The inherent limitations of a ball mill may be prohibitive, and exploring alternative milling technologies would be a necessary step.

Ultimately, the decision to use a ball mill is a deliberate choice to prioritize power and versatility over operational efficiency.

Summary Table:

| Limitation | Key Impact |

|---|---|

| High Energy Consumption | Significant operational cost; energy lost as heat and noise. |

| Consumable Wear | Ongoing cost for replacing grinding media and mill linings. |

| Significant Size & Weight | Demands substantial floor space and reinforced foundations. |

| Noise Pollution | Requires soundproofing or remote placement for safety compliance. |

Struggling to balance grinding power with operational efficiency? The limitations of ball mills are real, but choosing the right equipment is key. At KINTEK, we specialize in lab equipment and consumables, offering solutions tailored to your specific material processing needs—whether you require the robustness of a ball mill or a more efficient alternative. Let our experts help you optimize your laboratory's workflow. Contact KINTEK today for a personalized consultation!

Visual Guide

Related Products

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Laboratory Single Horizontal Jar Mill

- Laboratory Four-Body Horizontal Jar Mill

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

People Also Ask

- What is the primary function of a high energy nano mill? Optimize LiFePO4/C Composite Preparation

- Why Are High-Purity Alumina Grinding Balls Selected for Al2O3-TiCN/Co-Ni Powders? Ensure Chemical Purity

- What are the parameters of the ball mill process? Optimize Grinding for Efficiency and Particle Size

- What is the primary role of a light ball mill? Optimize SiC/Cu-Al2O3 Composite Powder Homogeneity

- What is the technical significance of adjusting ball mill rotation speeds to low levels? Optimize Composite Cathodes

- What is the role of a ball milling system in the physical synthesis of wüstite nanoparticles? Key Mechanisms Explained

- What size is a ball mill? A Guide from Benchtop to Industrial Scale

- What is the mechanism of action of a colloid mill? Master High-Shear Processing for Superior Emulsions and Dispersions