While the sieve shaker is a foundational tool in countless labs, its effectiveness is not universal. Its core limitations stem from fundamental assumptions about particle geometry and behavior, which can lead to significant inaccuracies if the instrument is misapplied.

The primary limitation of a sieve shaker is its reliance on a simple geometric test: can a particle pass through a square hole? This method becomes unreliable for very fine powders, non-spherical particles, and materials prone to breaking, leading to skewed particle size distribution data.

How a Sieve Shaker Works

To understand the limitations, we must first appreciate the mechanism. A sieve shaker is fundamentally a mechanical device designed for separating particles by size.

The Principle of Mechanical Separation

A sieve shaker uses a vibration motor to create a consistent, often three-dimensional, shaking or tapping motion. This motion drives a stack of nested test sieves with progressively smaller mesh openings from top to bottom.

As the stack vibrates, particles migrate across the sieve surface. Particles smaller than the mesh openings fall through to the next level, while larger particles are retained. This process continues until the sample is distributed across the sieves according to its size fractions.

Where Sieve Shakers Excel

For the right application, a sieve shaker is highly effective. Its automated operation provides fast and repeatable results, far exceeding the consistency of manual hand sieving.

It is a simple, cost-effective, and robust method for routine quality control and analysis of many granular materials. The ability to use a stack of up to 10 sieves allows for multi-level separation in a single run.

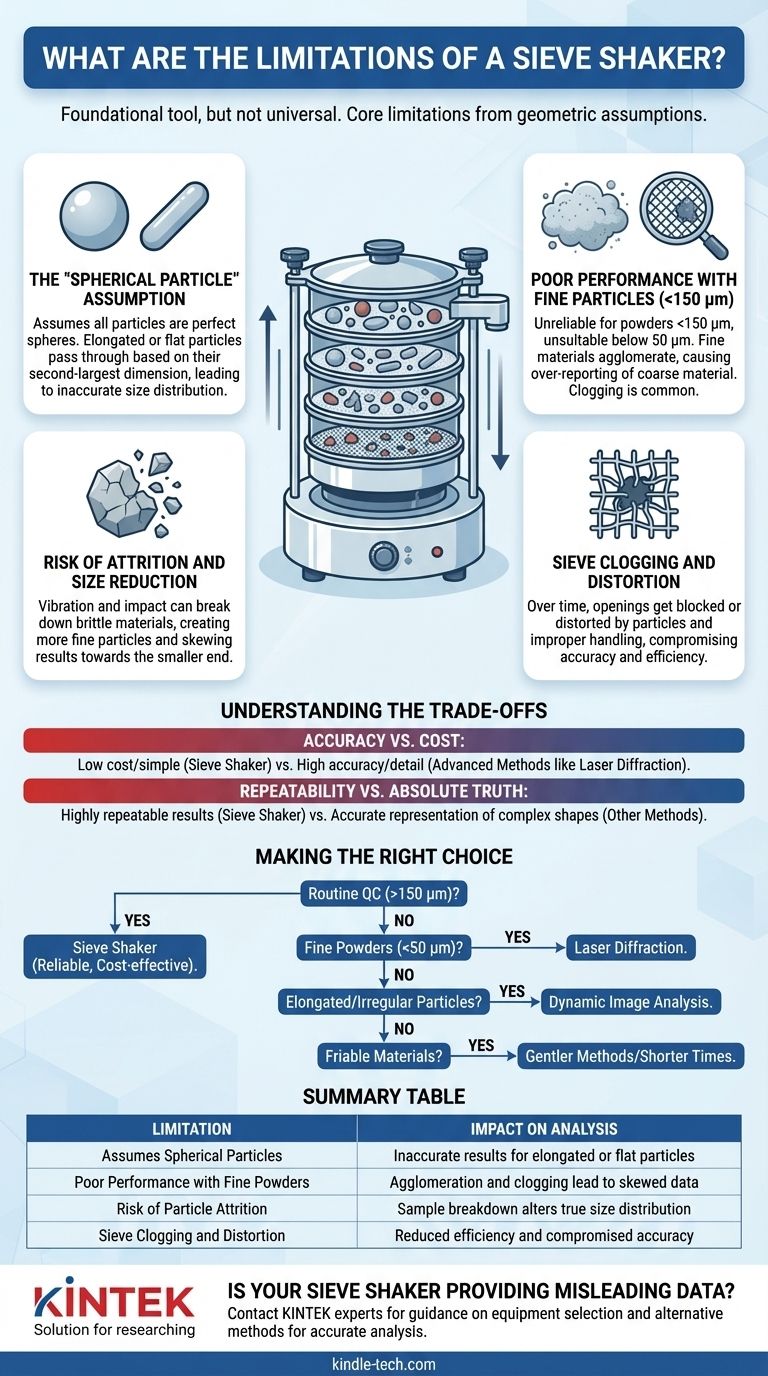

Unpacking the Core Limitations

The shaker's simplicity is also the source of its weaknesses. The results are only trustworthy when the material being tested aligns with the method's inherent assumptions.

The "Spherical Particle" Assumption

The most significant limitation is that sieve analysis implicitly assumes all particles are perfect spheres. It only measures whether a particle's second-largest dimension can pass through the sieve aperture.

For elongated or flat particles, this is highly problematic. A long, needle-like particle can easily pass through a sieve end-on, causing it to be classified in a much smaller size fraction than its actual length would suggest. This leads to an inaccurate, mass-based result that misrepresents the true particle size distribution.

The Challenge with Fine Particles

Sieve shakers become progressively less accurate for materials finer than 100 mesh (approximately 150 µm) and are generally unsuitable for particles smaller than 50 µm.

Fine powders tend to agglomerate due to forces like static electricity or moisture, preventing individual particles from passing through the mesh. This results in an over-reporting of coarse material. While wet sieving can sometimes help, it adds complexity to the process.

Risk of Attrition and Size Reduction

The very motion designed to separate particles can also damage them. The constant vibration and particle-on-particle impact can cause brittle materials to break down, an effect known as attrition.

This creates more fine particles than were present in the original sample, skewing the final distribution toward the smaller end of the scale and yielding incorrect results.

Sieve Clogging and Distortion

Over time and with improper use, sieve openings can become clogged or blinded by particles that are near the size of the aperture. This effectively reduces the open area of the sieve, hindering separation efficiency.

Furthermore, improper handling or cleaning can damage or distort the fine wire mesh, compromising the accuracy of the openings and rendering the analysis unreliable.

Understanding the Trade-offs

Choosing a sieve shaker means accepting a trade-off between simplicity and precision. Its value is entirely dependent on the context of your analysis.

Accuracy vs. Cost

Compared to advanced methods like laser diffraction or image analysis, a sieve shaker is significantly lower in cost and simpler to operate. However, those other methods provide far more accurate and detailed data, especially for fine or non-spherical particles.

Repeatability vs. Absolute Truth

A well-maintained sieve shaker provides highly repeatable results. If you run the same sample under the same conditions, you will get a very similar distribution.

However, this repeatable result may not be the absolute truth. For a sample of fibrous material, the results will be consistently wrong, but wrong in the same way every time. This may be acceptable for routine process control but is insufficient for research or developing precise specifications.

Making the Right Choice for Your Goal

Use these limitations to determine if a sieve shaker is the correct instrument for your specific application.

- If your primary focus is routine QC for granular, free-flowing materials (>150 µm): A sieve shaker is a highly reliable, repeatable, and cost-effective choice.

- If your primary focus is analyzing fine powders, emulsions, or materials below 50 µm: The limitations are critical, and you should explore alternative methods like laser diffraction.

- If your primary focus is characterizing elongated, flat, or irregularly shaped particles: Sieve analysis will provide misleading data, and you should use a method like dynamic image analysis.

- If your primary focus is analyzing friable materials that break easily: Be aware that the shaker's motion may alter your sample, and consider gentler methods or shorter sieving times.

Ultimately, understanding these constraints allows you to correctly apply sieve analysis where it excels and to seek more advanced methods when precision demands it.

Summary Table:

| Limitation | Impact on Analysis |

|---|---|

| Assumes Spherical Particles | Inaccurate results for elongated or flat particles |

| Poor Performance with Fine Powders (<150 µm) | Agglomeration and clogging lead to skewed data |

| Risk of Particle Attrition | Sample breakdown alters true size distribution |

| Sieve Clogging and Distortion | Reduced efficiency and compromised accuracy |

Is your sieve shaker providing misleading data for your specific materials?

Understanding the limitations of your equipment is the first step toward accurate particle analysis. The team at KINTEK specializes in helping laboratories select the right equipment for their unique needs.

We provide:

- Expert guidance on whether sieve analysis or an alternative method (like laser diffraction) is right for your application.

- A full range of reliable lab equipment and consumables to ensure your processes are precise and efficient.

Don't let instrument limitations compromise your results. Contact our experts today for a consultation to ensure your particle size analysis is accurate and reliable.

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Three-dimensional electromagnetic sieving instrument

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Multifunctional Small Speed-Adjustable Horizontal Mechanical Shaker for Lab

- Vibratory Sieve Shaker Machine Dry Three-Dimensional Vibrating Sieve

People Also Ask

- Why use a vibratory sieve shaker for PET powder? Achieve Precise Particle Size Control for Chemical Research

- What are the disadvantages of sieve machine? Key Limitations in Particle Size Analysis

- Why is powder classification using standard sieves essential for SHS reactions? Unlock Superior Nitriding Results

- What is the significance of using a fine sieving system for catalyst particles? Optimize Size for Maximum Reactivity

- Why is a standardized sieving system necessary for elephant grass research? Ensure Reliable Sample Consistency