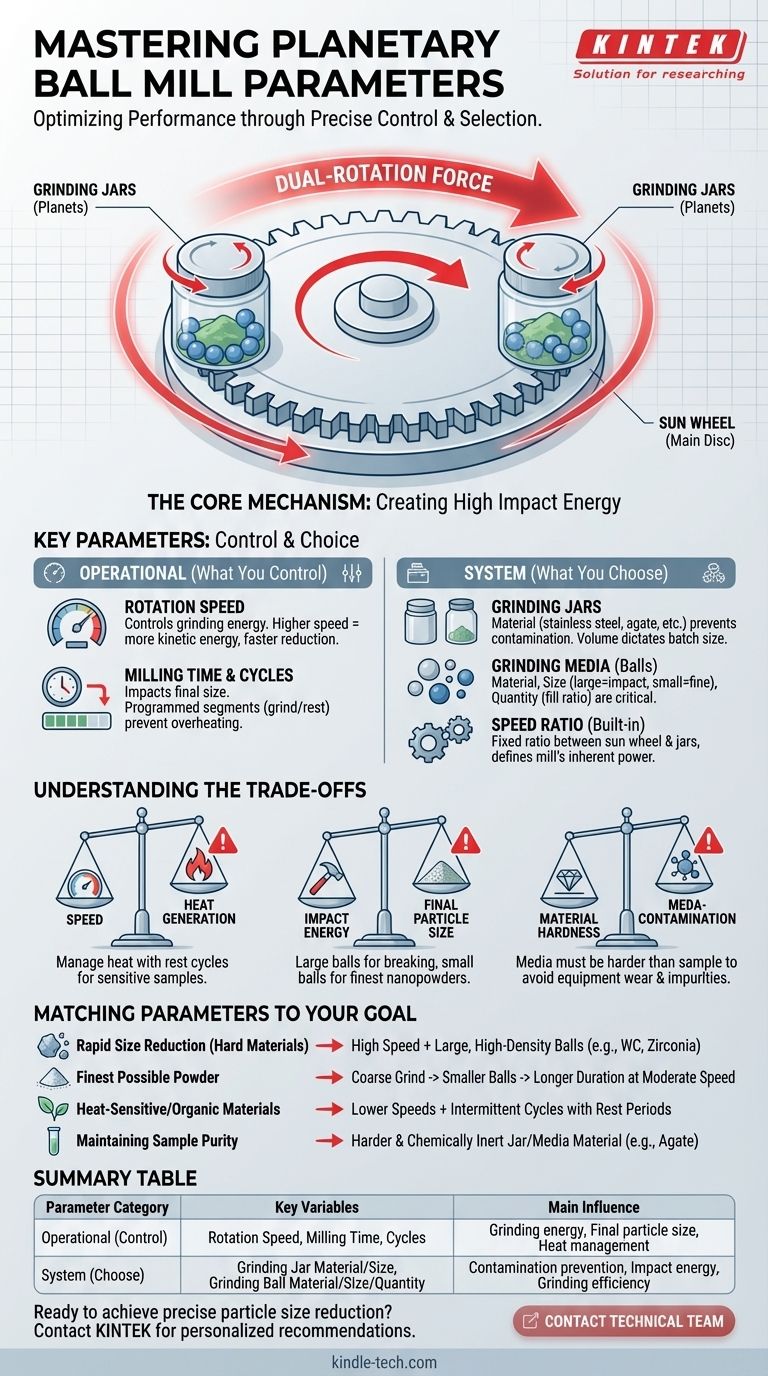

The primary parameters of a planetary ball mill are a combination of operational settings you control and physical components you select. The most critical operational parameters include the rotation speed of the main disc (the sun wheel) and the milling time. Equally important are the physical system parameters, such as the material and size of the grinding jars and the grinding media (the balls) within them.

A planetary ball mill's performance is not defined by a single setting, but by the interplay between its speed, duration, and the physical characteristics of the jars and balls. Mastering these parameters is about precisely controlling the collision energy needed to process your specific material.

The Core Mechanism: How Planetary Motion Creates Force

A planetary ball mill generates extremely high impact energy through a unique dual-rotation system. This is the foundation for understanding its parameters.

The Sun Wheel and Planets

The machine consists of a large, central rotating disc called the sun wheel. Mounted eccentrically on this wheel are one or more smaller grinding jars, which act as the "planets."

Opposing Rotational Forces

As the sun wheel turns in one direction, the grinding jars are forced to rotate on their own axes in the opposite direction. This superposition of movements results in extremely high centrifugal forces acting on the grinding media (balls) and the sample material inside the jars. The balls are thrown against the inner wall of the jar, crushing and grinding the material with immense energy.

Key Operational Parameters (What You Control)

These are the settings you will adjust for each milling session to influence the outcome.

Rotation Speed

The rotation speed of the sun wheel is the most direct way to control the grinding energy. A higher speed imparts more kinetic energy to the grinding balls, leading to more forceful impacts and faster particle size reduction.

Milling Time and Cycles

Milling duration directly impacts the final particle size; longer times generally produce finer powders. Modern mills feature programmable milling segments, allowing you to set cycles of milling followed by rest periods. This is crucial for preventing overheating, which can alter or damage sensitive materials.

Critical System Parameters (What You Choose)

These are the physical components you select before starting a milling operation. Your choices here are as important as your operational settings.

Grinding Jars

The jars contain the sample and the grinding media. Key considerations include material (e.g., stainless steel, agate, zirconia) to prevent sample contamination and volume, which dictates your maximum batch size.

Grinding Media (Balls)

The balls are the active grinding component. Their properties are paramount:

- Material: The balls must be harder than the material being ground to be effective and avoid introducing impurities.

- Size: Larger balls provide higher impact energy for breaking down coarse particles, while smaller balls offer more surface contact points for achieving a very fine final powder.

- Quantity (Fill Ratio): The ratio of the volume of balls to the volume of sample material significantly affects grinding efficiency.

Speed Ratio

The ratio between the sun wheel's speed and the grinding jars' speed is a fundamental design parameter of the machine itself. While not user-adjustable, this built-in ratio determines the mill's characteristic grinding power and efficiency.

Understanding the Trade-offs

Optimizing the milling process requires balancing competing factors.

Speed vs. Heat Generation

Higher speeds grind material faster but also generate significant heat. This can be detrimental to heat-sensitive samples, potentially causing phase changes, decomposition, or agglomeration. Using programmed rest cycles is the primary way to manage this.

Impact Energy vs. Final Particle Size

Using large, dense grinding balls creates powerful impacts ideal for breaking down hard, brittle materials quickly. However, to achieve the finest possible nanopowders, a subsequent milling step with smaller balls is often necessary to increase the frequency of grinding events over their raw power.

Material Hardness vs. Contamination

Always select grinding jars and balls made of a material that is significantly harder than your sample. If the sample is harder, it will abrade the media and jar walls, introducing contamination into your final product and ruining your equipment.

Matching Parameters to Your Goal

Use this guide to select a starting point for your specific application.

- If your primary focus is rapid size reduction of hard materials: Use high rotation speeds with large, high-density grinding balls (like tungsten carbide or zirconia).

- If your primary focus is achieving the finest possible powder: Start with a coarse grind, then switch to smaller grinding balls and run for a longer duration at a moderate speed.

- If your primary focus is processing heat-sensitive or organic materials: Use lower speeds and program intermittent cycles with sufficient rest periods to allow for cooling.

- If your primary focus is maintaining sample purity: Ensure your grinding jar and media material is both harder than your sample and chemically inert to it (e.g., using agate for certain chemical compounds).

By deliberately choosing your system components and controlling your operational settings, you can transform the planetary ball mill from a simple grinder into a precision processing instrument.

Summary Table:

| Parameter Category | Key Variables | Main Influence |

|---|---|---|

| Operational (What You Control) | Rotation Speed, Milling Time, Cycles | Grinding energy, Final particle size, Heat management |

| System (What You Choose) | Grinding Jar Material/Size, Grinding Ball Material/Size/Quantity | Contamination prevention, Impact energy, Grinding efficiency |

Ready to achieve precise particle size reduction and material processing? The right planetary ball mill is key to your success. KINTEK specializes in high-performance lab equipment, including planetary ball mills, and our experts can help you select the perfect machine, jars, and media for your specific materials and goals—whether you're working with hard ceramics, sensitive organics, or need nanoscale powders. Contact our technical team today to discuss your application and get a personalized recommendation!

Visual Guide

Related Products

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High Energy Planetary Ball Mill for Laboratory Horizontal Tank Type Milling Machine

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

People Also Ask

- What is a planetary milling machine used for? Achieve Nano-Scale Grinding for Hard & Soft Materials

- What is the role of a planetary ball mill in evaluating the processing performance of Miscanthus hydrochar?

- What are the effects of ball milling? A Deep Dive into Mechanical Alloying and Material Transformation

- What is the principle of planetary ball mill? Achieve Rapid, High-Energy Grinding for Your Materials

- What is the role of a planetary ball mill in the preparation of NiCr-Al2O3-SrCO3 composite powders? Enhanced Homogeneity