At their core, laboratory sieves are precision instruments used for particle size analysis. They are categorized primarily by their screen construction: wire mesh for general use, perforated metal plate for coarse materials, and high-precision electroformed sheets for extremely fine particles.

The type of laboratory sieve you choose is not arbitrary; it is a critical decision dictated by the size of the particles you need to measure and the level of accuracy your analysis requires.

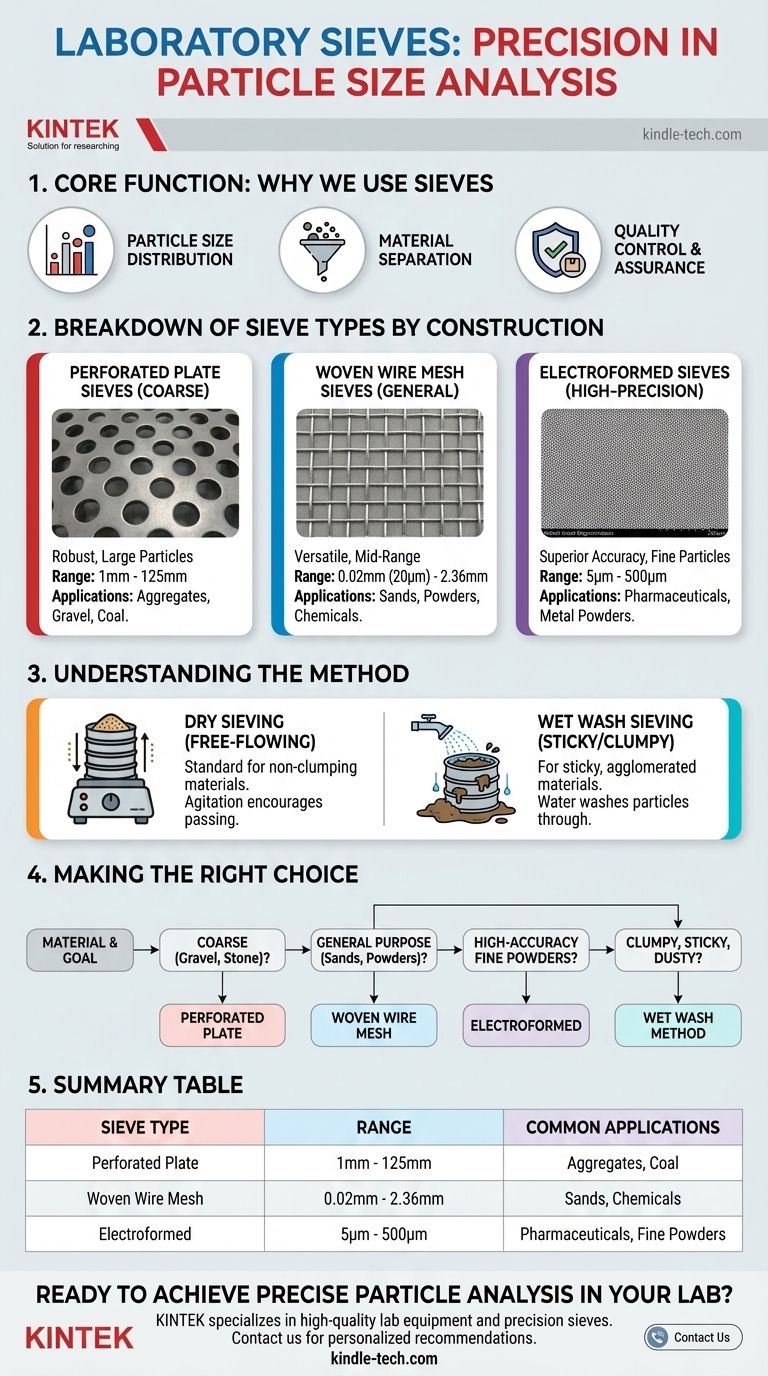

The Core Function: Why We Use Laboratory Sieves

The fundamental purpose of a laboratory sieve is to sort particles by size. This simple function is critical for quality control, research, and material classification across countless industries.

Particle Size Distribution Analysis

The primary application is to determine the range and proportion of different particle sizes within a sample. A stack of sieves with progressively smaller openings is used to separate the material into different size fractions, providing a detailed distribution profile.

Material Separation and Fractioning

Beyond analysis, sieves are used to physically separate a bulk material into specific size ranges. This is essential for preparing materials that must meet a size specification for a subsequent process or final product.

Quality Control and Assurance

Industries from pharmaceuticals to construction rely on sieving to ensure their raw materials and final products meet required standards. An incorrect particle size can dramatically affect a product's performance, safety, and consistency.

A Breakdown of Sieve Types by Construction

The physical construction of the sieve's screen determines its effective measurement range and ideal application.

Perforated Plate Sieves: For Coarse Materials

These sieves feature a solid sheet of metal with precisely punched holes, typically round or square. They are robust and designed for sorting larger particles.

Their measurement range is wide, typically from 1 mm up to 125 mm. This makes them the standard choice for aggregates, gravel, coal, and large agricultural products.

Woven Wire Mesh Sieves: The General-Purpose Standard

This is the most common type of laboratory sieve. It consists of a stainless steel or brass wire cloth with precisely woven square openings.

Woven mesh sieves cover the mid-range of particle sizes, from approximately 0.02 mm (20 microns) to 2.36 mm. They are highly versatile and used for analyzing sands, powders, flours, chemicals, and soil.

Electroformed Sieves: For High-Precision Microns

Electroforming creates extremely precise and thin nickel sheets with highly uniform openings. These are not woven or punched but grown through an additive process, resulting in superior accuracy.

Used for advanced applications, these sieves measure very fine particles, typically from 5 microns up to 500 microns. They are essential in the pharmaceutical, metal powder, and chemical industries where precision is paramount.

Understanding the Method: Dry vs. Wet Sieving

The type of material being tested dictates the method used to pass it through the sieve.

Dry Sieving

This is the standard method for materials that are free-flowing and do not clump together. The sample is placed in the top sieve of a stack, which is then agitated by a mechanical shaker to encourage particles to pass through the openings.

Wet Wash Sieving

This technique is necessary when particles are sticky, tend to agglomerate, or are coated in fine dust like clay or silt. Water is introduced to the sample to help wash the particles through the sieve openings and break up any clumps. This is common in the aggregate and soil industries to ensure an accurate measurement of the base particle.

Making the Right Choice for Your Goal

Selecting the correct sieve is the first step toward accurate and repeatable particle analysis. Your decision should be guided by the material you are testing and the data you need.

- If your primary focus is coarse materials like gravel, stone, or large grains: You need the durability and large openings of a Perforated Plate Sieve.

- If your primary focus is general-purpose powders, sands, or soils: The versatility of a Woven Wire Mesh Sieve is your most reliable choice.

- If your primary focus is high-accuracy analysis of very fine powders: The unparalleled precision of an Electroformed Sieve is required.

- If your material is clumpy, sticky, or coated with fine dust: You must employ a Wet Wash Sieving method to ensure accurate separation.

Ultimately, understanding these distinctions ensures the integrity and reliability of your particle size data.

Summary Table:

| Sieve Type | Measurement Range | Common Applications |

|---|---|---|

| Perforated Plate | 1 mm - 125 mm | Aggregates, gravel, coal, large grains |

| Woven Wire Mesh | 0.02 mm (20 microns) - 2.36 mm | Sands, powders, flours, chemicals, soil |

| Electroformed | 5 microns - 500 microns | Pharmaceuticals, metal powders, fine chemicals |

Ready to Achieve Precise Particle Analysis in Your Lab?

Choosing the right laboratory sieve is critical for accurate quality control and reliable research. KINTEK specializes in providing high-quality lab equipment and consumables, including a full range of precision sieves for every application—from coarse aggregates to fine pharmaceutical powders.

Our experts can help you select the ideal sieve type and method (dry or wet sieving) to ensure your particle size data is consistently accurate. Enhance your lab's efficiency and data integrity with KINTEK's reliable solutions.

Contact us today to discuss your specific sieving needs and get a personalized recommendation!

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Three-dimensional electromagnetic sieving instrument

- Laboratory Wet Three-Dimensional Vibratory Sieve Shaker Machine

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

People Also Ask

- Why use a standard sieve for Prosopis juliflora pretreatment? Ensure Precision in Particle Size Control

- What are the uses of sieves in the laboratory? Master Particle Size for Quality & Performance

- How sieve analysis is conducted in the Laboratory? A Step-by-Step Guide to Accurate Particle Sizing

- Why must the crushing and sieving of Mg3Sb2 powder be conducted within an Argon atmosphere? Protect Material Integrity

- Why is sieve analysis important in geotechnical engineering? Unlock Soil Behavior for Safer Construction

- What are the standard sieve sizes used in food industry? A Guide to ASTM, Tyler, and ISO Standards

- What type of materials can be separated using the method of sieving? A Guide to Efficient Particle Size Separation

- What is the standard for sieve analysis? A Guide to ASTM & ISO Compliance