In the pharmaceutical industry, a colloid mill is a high-shear rotor-stator mixer used to reduce the particle size of solids or droplets in a liquid. Its primary purpose is to produce highly stable, uniform dispersions such as emulsions, suspensions, and ointments, ensuring product consistency, stability, and bioavailability.

A colloid mill is not just a simple mixer; it is a precision instrument for particle size reduction and homogenization. It applies intense mechanical force to break down materials, transforming coarse mixtures into the fine, stable formulations required for effective and safe pharmaceutical products.

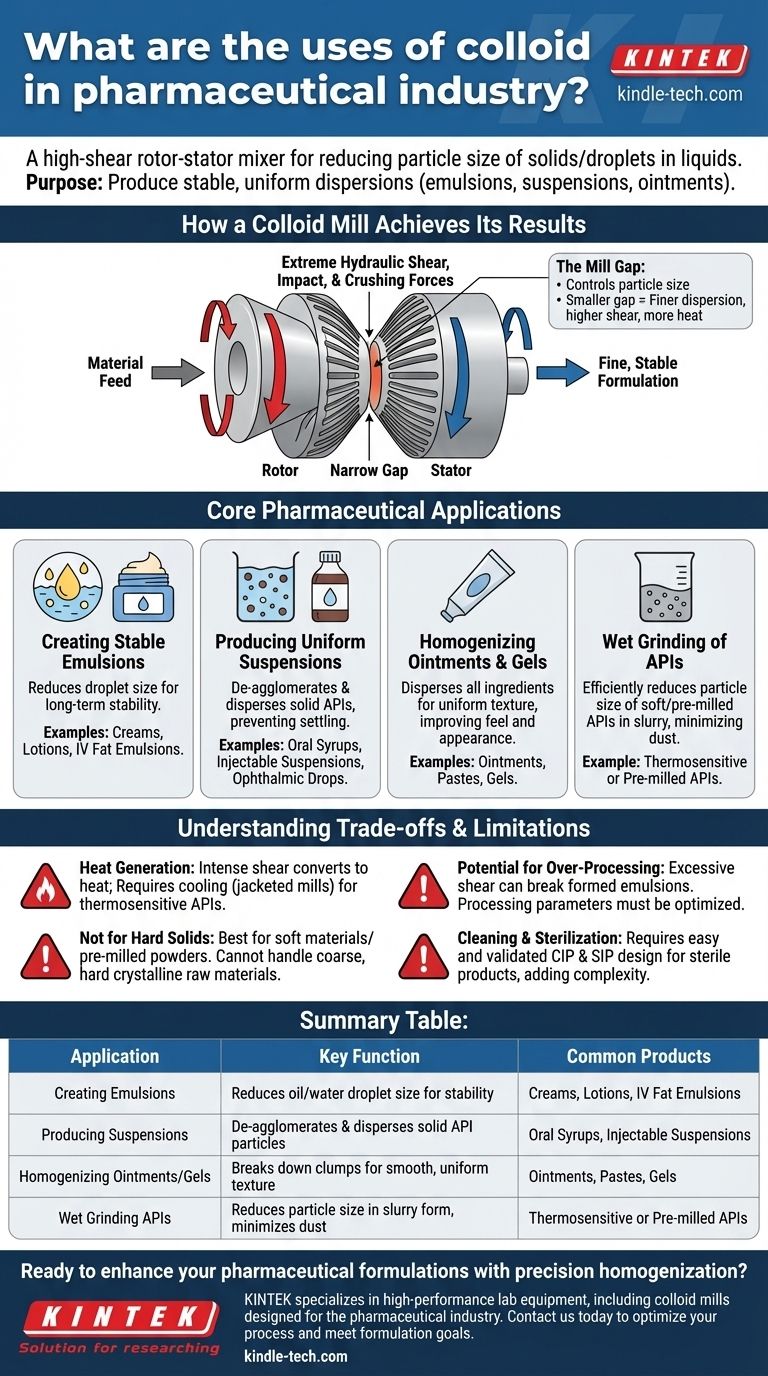

How a Colloid Mill Achieves Its Results

A colloid mill's effectiveness comes from its unique mechanical design, which generates extreme hydraulic shear on the material being processed. Understanding this mechanism is key to appreciating its applications.

The Rotor-Stator Mechanism

The core of the mill consists of two primary components: a high-speed rotating element called the rotor and a stationary element called the stator. Both are cone-shaped and feature intricate patterns of grooves or teeth.

The material is fed into the gap between the rotor and stator. The rotor spins at very high speeds (typically 3,000 to 18,000 RPM), creating powerful centrifugal force that pushes the material outwards through the toothed assembly.

The Primary Forces: Shear, Impact, and Crushing

As the material is forced through the narrow gap, it is subjected to a combination of intense forces. The primary force is hydraulic shear, which tears particles and droplets apart.

Additionally, the material experiences high-frequency mechanical crushing and impact between the rotor's teeth and the stator's teeth, further contributing to particle size reduction.

Controlling the Outcome: The Mill Gap

The degree of particle size reduction is controlled by adjusting the physical gap between the rotor and the stator. This gap can be precisely set, often from fractions of a millimeter down to a few microns.

A smaller gap results in higher shear and a finer dispersion, but it also increases heat generation and reduces the flow rate.

Core Pharmaceutical Applications

The colloid mill's ability to create fine, uniform dispersions makes it indispensable for manufacturing a wide range of pharmaceutical dosage forms.

Creating Stable Emulsions

Emulsions are mixtures of two immiscible liquids, like oil and water. A colloid mill is used to break down the dispersed phase (e.g., oil droplets) to a microscopic size, allowing them to be stabilized by an emulsifying agent.

This is critical for products like creams, lotions, and intravenous fat emulsions, where stability and texture are paramount.

Producing Uniform Suspensions

Suspensions contain solid particles of an active pharmaceutical ingredient (API) dispersed in a liquid vehicle. The mill ensures these particles are de-agglomerated and reduced to a uniform size.

This prevents the solids from settling quickly (caking) and guarantees dose uniformity in products like oral antibiotic syrups, injectable suspensions, and some ophthalmic drops.

Homogenizing Ointments and Gels

For semi-solid preparations like ointments, pastes, and gels, a colloid mill ensures all ingredients are thoroughly and uniformly dispersed. This improves the product's therapeutic efficacy, feel, and appearance.

It breaks down any clumps of active ingredients or excipients, resulting in a smooth, homogenous final product.

Wet Grinding of APIs

While not a primary grinder for hard crystals, a colloid mill is excellent for the wet milling of softer APIs or pre-milled powders. By processing the API as a slurry, it efficiently reduces particle size while minimizing dust generation, which is a major safety benefit.

Understanding the Trade-offs and Limitations

While highly effective, a colloid mill is not a universal solution. Its use involves critical trade-offs that must be managed.

Heat Generation: A Critical Concern

The intense shear energy imparted by the mill is largely converted into heat. This can be a significant problem when processing thermosensitive APIs or excipients, potentially causing degradation of the drug or destabilization of the formulation.

Many industrial colloid mills are jacketed, allowing for a cooling liquid to circulate and mitigate temperature increases.

Not a Primary Grinder for Hard Solids

A colloid mill is not designed to break down large, hard, or highly crystalline raw materials from scratch. It is most effective on soft materials or on solids that have already been pre-milled into a finer powder.

Attempting to mill hard, coarse materials can cause excessive wear on the rotor and stator and may not achieve the desired particle size.

Potential for Over-Processing

For some formulations, particularly emulsions, excessive shear can be detrimental. Over-processing can sometimes break an emulsion that has already formed, leading to phase separation. The processing time and mill gap must be carefully optimized.

Cleaning and Sterilization Requirements

For sterile products like injections or ophthalmic solutions, the colloid mill must be designed for easy and validated Clean-in-Place (CIP) and Sterilize-in-Place (SIP) procedures. This adds complexity and cost to the equipment design.

Making the Right Choice for Your Goal

The decision to use a colloid mill depends on your specific formulation and manufacturing objective.

- If your primary focus is creating a stable cream or lotion: A colloid mill is the ideal tool for reducing oil droplet size to ensure long-term stability and a desirable skin feel.

- If your primary focus is ensuring dose uniformity in a liquid suspension: A colloid mill effectively de-agglomerates and disperses the API powder, preventing settling and ensuring each dose is consistent.

- If your primary focus is improving the smoothness of an ointment: Use a colloid mill to break down any gritty particles of the drug or excipients, resulting in a homogenous and elegant final product.

- If your primary focus is milling a heat-sensitive API: A colloid mill can be used, but you must select a jacketed model and carefully control processing parameters to manage the temperature rise.

By applying intense, controlled shear, the colloid mill provides the mechanical power necessary to build quality and stability directly into pharmaceutical formulations.

Summary Table:

| Application | Key Function | Common Pharmaceutical Products |

|---|---|---|

| Creating Emulsions | Reduces oil/water droplet size for stability | Creams, Lotions, IV Fat Emulsions |

| Producing Suspensions | De-agglomerates & disperses solid API particles | Oral Syrups, Injectable Suspensions |

| Homogenizing Ointments/Gels | Breaks down clumps for smooth, uniform texture | Ointments, Pastes, Gels |

| Wet Grinding APIs | Reduces particle size in slurry form, minimizes dust | Thermosensitive or Pre-milled APIs |

Ready to enhance your pharmaceutical formulations with precision homogenization?

KINTEK specializes in high-performance lab equipment, including colloid mills designed for the rigorous demands of the pharmaceutical industry. Our solutions help you achieve superior particle size reduction, stable emulsions, and uniform suspensions—ensuring product consistency, stability, and bioavailability for your creams, ointments, injectables, and more.

Contact us today to discuss how our colloid mills can optimize your manufacturing process and meet your specific formulation goals. Get in touch now!

Visual Guide

Related Products

- Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

- Laboratory Micro Tissue Grinding Mill Grinder

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Laboratory Single Horizontal Jar Mill

- Laboratory Four-Body Horizontal Jar Mill

People Also Ask

- What is the primary function of vibration milling in Heusler alloy preparation? Achieve High-Reactivity Fine Powders

- What is the difference between a ball mill and a colloidal mill? Choose the Right Mill for Your Process

- What is the importance of speed of rotation of a ball mill cylinder? Unlock Maximum Grinding Efficiency

- What role does an industrial-grade dry vibration mill play in ODS alloy preparation? Master High-Energy Material Milling

- Why is an agate mortar used for manual grinding? Ensure Purity in LLZO Electrolyte Mixing

- What is the primary function of a high-energy ball mill? Ensure Uniformity in Mo-W-Ta-Ti-Zr Refractory Alloys

- What mechanism does a high-pressure homogenizer use for PHA extraction? Physical Disruption for Sustainable Recovery

- What is the function of mechanical grinding equipment in lignocellulosic pretreatment? Maximize Yeast Biodiesel Yields