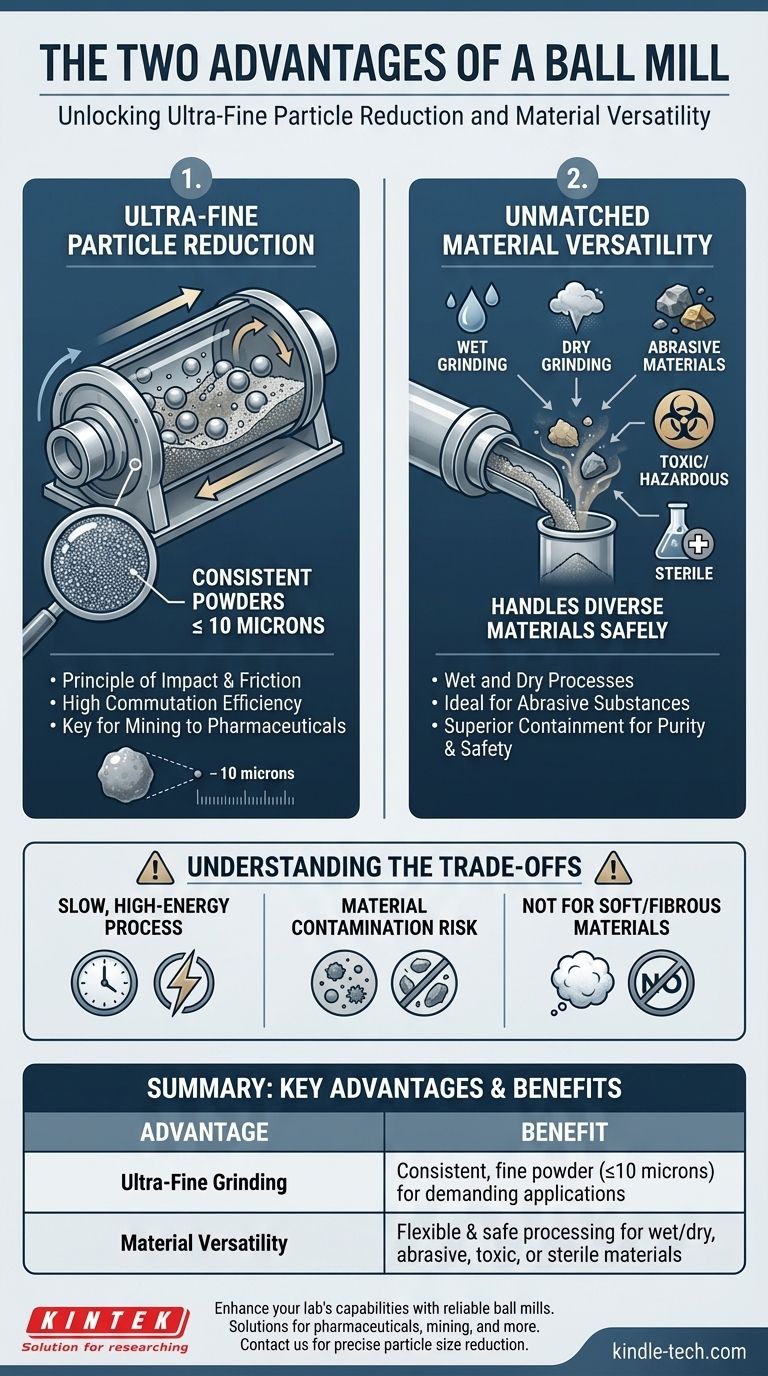

In short, the two primary advantages of a ball mill are its ability to produce extremely fine powders and its versatility in processing a wide range of materials. This simple machine achieves consistent particle sizes of 10 microns or less, making it a foundational tool in industries from mining to pharmaceuticals. Its enclosed design also allows it to safely handle abrasive, toxic, or sterile substances.

A ball mill's true value lies not just in its grinding capability, but in its reliability. It is a proven, robust solution for achieving consistent, ultra-fine particle reduction across a vast spectrum of materials where other methods might fail.

The Core Capabilities of a Ball Mill

To understand if a ball mill is right for your application, you need to look beyond a simple list of features and understand the specific problems it solves.

Achieving Ultra-Fine Particle Reduction

A ball mill excels at comminution, the process of reducing solid materials from one average particle size to a smaller average particle size.

It uses the principles of impact and friction. As the cylinder rotates, the grinding media (the balls) are lifted and then tumble down, crushing and grinding the material trapped between them. This continuous action is highly effective at producing very fine powders.

The ability to consistently achieve a particle size of 10 microns or less is a key performance indicator and a primary reason for its selection.

Unmatched Material Versatility

Ball mills are not specialized for a single type of material, which makes them a flexible asset.

They can be used for both wet and dry grinding processes. Adding a liquid can prevent material agglomeration and help control the temperature inside the mill.

Furthermore, they are highly effective at milling abrasive materials like mining ores, coal, and pigments, which would quickly wear down other types of grinding equipment.

Superior Containment and Purity

The simple, enclosed cylinder design offers significant advantages for sensitive applications.

Because the system is sealed, it is ideal for grinding toxic or hazardous materials without exposing operators or the environment.

This same sealed design is critical in pharmaceutical manufacturing, where it can maintain the sterility of parenteral or ophthalmic products during milling.

Reliability in Continuous Operation

Ball mills are known for their robust construction and operational simplicity.

They are designed for continuous, long-term operation with minimal oversight. This makes them reliable workhorses in industrial production lines.

Service and maintenance are straightforward, often involving little more than the periodic addition of new grinding balls to compensate for wear.

Understanding the Trade-offs

No technology is a universal solution. The ball mill's strengths come with inherent limitations that are critical to understand.

It Is a Slow, High-Energy Process

The fine grinding achieved by a ball mill requires time. The process is inherently slow compared to coarser grinding methods.

This extended operation time means it can be energy-intensive. It also generates significant noise and vibration, which must be accounted for during installation.

Material Contamination Is a Factor

While the closed system prevents external contamination, the grinding process itself can be a source of impurities.

The constant impact and friction cause wear on both the grinding balls and the internal lining of the mill. This wear debris can mix with and contaminate the final product. The choice of grinding media is therefore critical for purity-sensitive applications.

Not Suitable for All Material Types

The crushing and impact mechanism of a ball mill is ineffective on certain materials.

It cannot properly mill soft, tacky, or fibrous materials. These substances tend to coat the grinding media or agglomerate into clumps rather than breaking down into a fine powder.

Making the Right Choice for Your Goal

To determine if a ball mill fits your needs, consider your primary objective.

- If your primary focus is producing the finest possible powder (≤ 10 microns): A ball mill is an exceptional choice, especially for hard, brittle, or abrasive materials.

- If your primary focus is processing hazardous or sterile materials: The enclosed design of a ball mill provides a significant safety and purity advantage over open-circuit grinders.

- If your primary focus is speed and high-volume throughput: You must weigh the slow batch speed against the mill's potential for reliable, continuous operation to see if it fits your production goals.

- If your primary focus is processing soft, fibrous, or heat-sensitive materials: You should explore alternative grinding methods, as a ball mill is likely unsuitable for your needs.

Ultimately, the ball mill remains an indispensable tool for its unique ability to deliver consistent, ultra-fine powders from even the most challenging materials.

Summary Table:

| Advantage | Key Feature | Benefit |

|---|---|---|

| Ultra-Fine Grinding | Achieves particle sizes of 10 microns or less | Consistent, fine powder production for demanding applications |

| Material Versatility | Handles wet/dry grinding, abrasive, toxic, or sterile materials | Flexible and safe processing across industries like mining and pharmaceuticals |

Ready to enhance your lab's grinding capabilities with a reliable ball mill? KINTEK specializes in high-quality lab equipment, including ball mills designed for precise particle size reduction and versatile material processing. Whether you're in pharmaceuticals, mining, or materials science, our solutions ensure safety, efficiency, and consistent results. Contact us today to find the perfect ball mill for your laboratory needs!

Visual Guide

Related Products

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- Laboratory Single Horizontal Jar Mill

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Laboratory Four-Body Horizontal Jar Mill

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

People Also Ask

- What is the function of an agate mortar and pestle? Ensure Purity in Halide Solid-State Electrolyte Synthesis

- What is the product size achieved by hammer mill? Control Your Grind with Screen Size & Speed

- What does a colloid mill do? Achieve Superior Emulsions and Fine Dispersions

- How does a high-efficiency homogenizing mixer contribute to the preparation of Tobermorite and Xonotlite precursors?

- Why is an alumina mortar used for grinding dried Yttrium Oxide precursor materials? Ensure Maximum Purity and Quality

- What is the primary function of mechanical grinding in 2G biomass pretreatment? Unlock High-Yield Conversion

- Why is high-energy ball milling required for zirconium disilicide PDCs? Unlock Precision Filler Activation

- What is the function of a mortar and pestle in ZnS nanoparticle prep? Optimize Your Sample Refinement