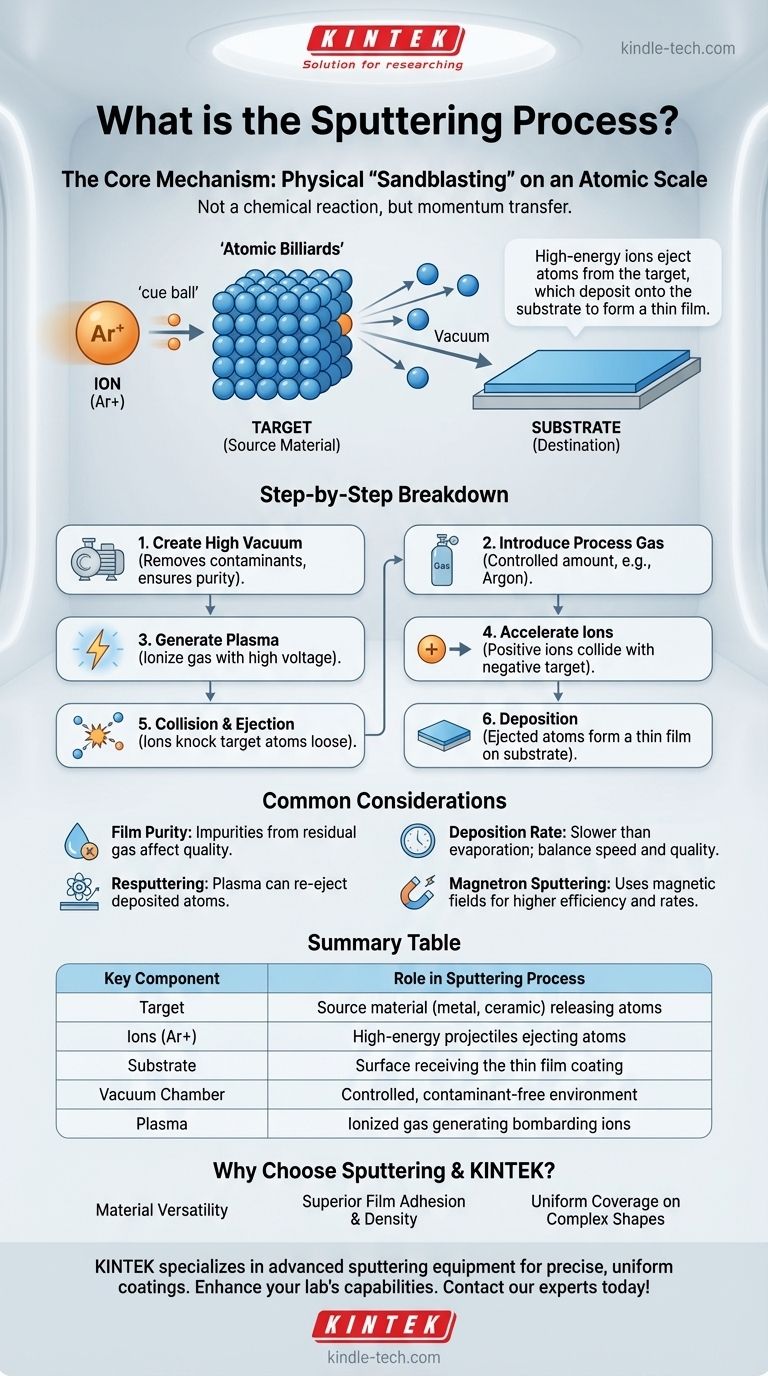

In essence, sputtering is a physical "sandblasting" on an atomic scale. It is a vacuum deposition technique where a source material, known as a target, is bombarded by high-energy ions. This collision has enough force to physically knock atoms loose from the target, which then travel through the vacuum and deposit onto a separate object, forming an extremely thin and uniform coating.

Sputtering is not a chemical reaction but a physical process of momentum transfer. By using energized ions to mechanically eject atoms from a source material in a vacuum, it provides a highly controlled and versatile method for creating high-quality thin films on a substrate.

The Fundamental Principle: Atomic Billiards

To truly understand sputtering, it's best to visualize a game of billiards played at the atomic level. The process relies on pure momentum and energy transfer between particles.

The Target: The Source Material

The target is a solid piece of the material you wish to deposit as a thin film. This could be a pure metal like titanium, an alloy, or a ceramic compound. In our analogy, this is the rack of billiard balls you want to break apart.

The Ions: The "Cue Balls"

Positively charged ions, typically from an inert gas like argon, are the projectiles. They are accelerated with high energy and directed at the target. These are the "cue balls" of the process, possessing the kinetic energy needed to cause a reaction.

The Substrate: The Destination

The substrate is the object or component that you intend to coat. It is strategically placed to intercept the atoms that are ejected from the target. The substrate is where the thin film is ultimately formed.

How Sputtering Works: A Step-by-Step Breakdown

The entire process takes place inside a sealed chamber and follows a precise sequence to ensure the purity and quality of the resulting film.

Step 1: Creating the Vacuum

First, the deposition chamber is pumped down to a very low pressure, creating a high vacuum. This is critical to remove air, moisture, and other contaminants that could interfere with the process or become trapped in the film.

Step 2: Introducing the Process Gas

A small, controlled amount of a high-purity inert gas, most commonly argon, is introduced into the chamber. The pressure remains very low, but there are now enough argon atoms to fuel the process.

Step 3: Generating the Plasma

A high voltage is applied across the chamber, creating a strong electric field. This field energizes the argon gas, stripping electrons from the argon atoms and creating a glowing, ionized gas known as a plasma. This plasma is a mix of positive argon ions (Ar+) and free electrons.

Step 4: Accelerating the Ions

The target material is given a strong negative electrical charge, making it the cathode. The positively charged argon ions in the plasma are naturally and powerfully accelerated toward this negatively charged target.

Step 5: The Collision and Ejection

The high-speed argon ions collide with the surface of the target. This impact transfers a significant amount of kinetic energy, physically dislodging or "sputtering" atoms from the target material. These ejected atoms are neutral and travel in a straight line from the point of impact.

Step 6: Deposition onto the Substrate

The ejected target atoms traverse the vacuum chamber and land on the cooler substrate. As they accumulate layer by layer, they form a dense, uniform, and highly adherent thin film.

Common Pitfalls and Considerations

While powerful, the sputtering process has characteristics and potential issues that require careful management for optimal results.

Film Purity is Paramount

The quality of the initial vacuum and the purity of the process gas directly impact the final film. Any residual gases like oxygen or water vapor can react with the depositing material, creating unintended compounds and impurities in the coating.

Understanding Deposition Rates

Sputtering is generally a slower deposition process compared to thermal evaporation. The rate depends on the energy of the ions, the type of target material, and the chamber pressure. Optimizing for speed can sometimes compromise film quality.

The Concept of Resputtering

Resputtering can occur when energetic particles in the plasma bombard the substrate itself, knocking off atoms that have already been deposited. This can affect the film's growth rate and final structure if not properly controlled.

Use of Magnetic Fields

Many modern systems use magnetron sputtering. A magnetic field is placed behind the target to trap the energetic free electrons from the plasma near the target's surface. This dramatically increases the ionization efficiency of the argon gas, allowing the process to run at lower pressures and achieve higher deposition rates.

Making the Right Choice for Your Goal

Understanding the sputtering mechanism allows you to determine if it is the correct process for your specific application.

- If your primary focus is material versatility: Sputtering is ideal, as it can deposit a vast range of materials, including pure metals, complex alloys, and even insulating ceramics that are difficult to process with other methods.

- If your primary focus is film adhesion and density: The high kinetic energy of the sputtered atoms results in exceptionally dense films with superior adhesion to the substrate compared to many other techniques.

- If your primary focus is coating complex shapes: Sputtered atoms arrive at the substrate from many angles due to gas scattering, providing excellent, uniform coverage over intricate and non-flat surfaces.

By understanding its core mechanism of physical momentum transfer, you can leverage sputtering to engineer surfaces with precisely tailored properties for advanced applications.

Summary Table:

| Key Component | Role in Sputtering Process |

|---|---|

| Target | Source material (metal, ceramic) that gets bombarded to release atoms |

| Ions (Ar+) | High-energy projectiles that physically eject atoms from the target |

| Substrate | Surface receiving the coating where thin film forms |

| Vacuum Chamber | Controlled environment free of contaminants for pure deposition |

| Plasma | Ionized gas that generates the ions needed for bombardment |

Need high-quality thin films for your research or production? KINTEK specializes in advanced sputtering equipment and consumables for laboratories requiring precise, uniform coatings. Our solutions deliver superior film adhesion, material versatility, and consistent results for complex applications. Contact our experts today to discuss how our sputtering systems can enhance your laboratory's capabilities!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Evaporation Boat for Organic Matter

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

People Also Ask

- How does chemical vapor deposition work carbon nanotubes? Scalable, Controlled Synthesis Explained

- Can monocrystalline graphene be grown on polycrystalline metal substrates? Unlock High-Quality CVD Graphene Synthesis

- What is the thin film deposition method? A Guide to PVD & CVD Techniques

- How many types of sputter are there? A Guide to DC, RF, Magnetron & Reactive Sputtering

- What is the chemical method to synthesis carbon nanotubes? Master CVD for High-Quality, Scalable Production

- What are the advantages of low pressure chemical vapor deposition? Achieve Superior Film Uniformity & Purity

- What role do heating filaments play in HWCVD systems? Master Low-Temp nanocrystalline SiC:H Film Deposition

- What is the Physical Vapor Deposition method? A Guide to High-Performance Thin-Film Coating