At its core, a colloid mill is a high-shear rotor-stator mixer designed for particle size reduction and dispersion. It forces a fluid (or a fluid containing solids) through a very narrow gap between a rapidly spinning rotor and a stationary stator. This action subjects the material to intense mechanical shear, breaking down particles or droplets to create a stable, homogenous mixture known as a colloidal suspension or emulsion.

A colloid mill is not just a blender; it is a precision instrument for deagglomeration and emulsification. Its primary purpose is to reduce the size of particles or droplets already in a liquid phase to achieve a fine, uniform, and stable final product.

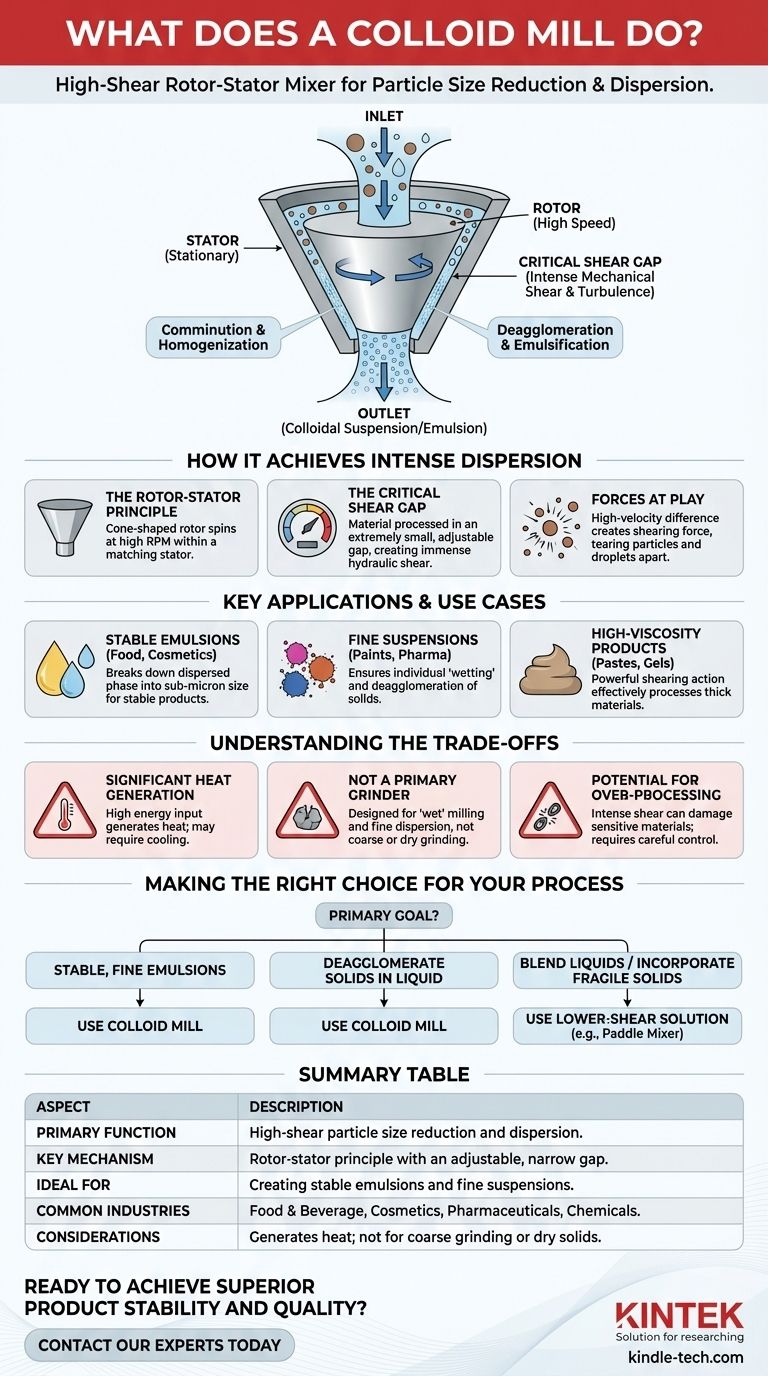

How a Colloid Mill Achieves Intense Dispersion

A colloid mill's effectiveness comes from its simple but powerful mechanical design. It generates forces far beyond what standard mixers can produce.

The Rotor-Stator Principle

The heart of the mill consists of two main parts: a rotor and a stator. The rotor is a cone-shaped component that spins at very high speeds (often thousands of RPM). The stator is a matching, stationary cone that perfectly encases the rotor.

The Critical Shear Gap

The material is processed in the extremely small, precisely controlled gap between the rotor and stator surfaces. This gap can typically be adjusted to control the amount of shear applied to the product.

As the material is fed into the mill, the high-speed rotor accelerates it centrifugally. It is then forced through the narrow gap, creating immense hydraulic shear and turbulence.

Forces at Play: Comminution and Homogenization

Within this gap, several forces act on the material simultaneously. The high-velocity difference between the spinning rotor and the fixed stator creates a powerful shearing force that tears particles and droplets apart.

This process is a form of comminution (particle size reduction) and homogenization (making the mixture uniform). It excels at breaking apart clumps of solid particles (deagglomeration) or breaking down large liquid droplets into smaller ones to form a stable emulsion.

Key Applications and Use Cases

The ability to create fine, stable mixtures makes the colloid mill essential in numerous industries.

Creating Stable Emulsions

For immiscible liquids like oil and water, a colloid mill is used to break down the dispersed phase (e.g., oil droplets) into a sub-micron size. This creates a high-surface-area, stable emulsion that resists separation, critical for products like mayonnaise, salad dressings, creams, and lotions.

Producing Fine Suspensions

When dispersing solid particles into a liquid, the mill's intense shear ensures that every particle is individually "wetted" by the liquid and that any clumps or agglomerates are broken apart. This is vital for producing high-quality paints, inks, pharmaceutical suspensions, and coatings.

Processing High-Viscosity Products

Colloid mills are often designed to handle thick, viscous materials. Their powerful shearing action can effectively process pastes and gels that would overwhelm standard mixers, ensuring a smooth, lump-free final texture.

Understanding the Trade-offs

While powerful, a colloid mill is a specialized tool and not a universal solution for all mixing needs.

Significant Heat Generation

The high mechanical energy input generates substantial heat. This can be a major issue for heat-sensitive materials like certain proteins or active pharmaceutical ingredients. Processes may require an external cooling jacket to manage the temperature.

Not a Primary Grinder

A colloid mill is a "wet" mill designed for fine dispersion, not coarse grinding. It cannot handle large, dry solids. Materials must be pre-milled or already in a slurry form before being introduced to the mill for final homogenization.

Potential for Over-Processing

The same intense shear that makes a colloid mill effective can also damage certain products. For example, over-shearing can break down long-chain polymers, destroying the desired viscosity or texture in some formulations. Careful control of the gap size and processing time is essential.

Making the Right Choice for Your Process

Deciding whether to use a colloid mill depends entirely on your final product goal.

- If your primary focus is creating stable, fine emulsions (e.g., food, cosmetics): The colloid mill is an excellent tool for reducing droplet size and ensuring long-term product stability.

- If your primary focus is deagglomerating solids in a liquid (e.g., pigments, APIs): The high shear is ideal for breaking apart clumps and achieving a uniform, high-quality dispersion.

- If your primary focus is simply blending liquids or incorporating fragile solids: A lower-shear solution, such as a paddle mixer or agitator, is a more appropriate and energy-efficient choice.

By understanding its principle of intense mechanical shear, you can effectively leverage a colloid mill to achieve superior product stability and quality.

Summary Table:

| Aspect | Description |

|---|---|

| Primary Function | High-shear particle size reduction and dispersion. |

| Key Mechanism | Rotor-stator principle with an adjustable, narrow gap. |

| Ideal For | Creating stable emulsions and fine suspensions. |

| Common Industries | Food & Beverage, Cosmetics, Pharmaceuticals, Chemicals. |

| Considerations | Generates heat; not for coarse grinding or dry solids. |

Ready to achieve superior product stability and quality?

A colloid mill from KINTEK is the precision instrument you need for creating stable emulsions, fine suspensions, and processing high-viscosity materials. Whether you are developing new food products, cosmetics, pharmaceuticals, or industrial chemicals, our expertise in lab equipment ensures you get the right solution for your specific dispersion and homogenization challenges.

Contact our experts today to discuss how KINTEK's colloid mills can enhance your laboratory processes and deliver the consistent, high-quality results you demand.

Visual Guide

Related Products

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Laboratory Grinding Mill Mortar Grinder for Sample Preparation

- Laboratory Single Horizontal Jar Mill

- Laboratory Four-Body Horizontal Jar Mill

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

People Also Ask

- What are the factors affecting grinding efficiency? Optimize Your Process for Maximum Output

- What is the difference between a ball mill and a sag mill? A Guide to Primary vs. Secondary Grinding

- What is the product size of a ball mill? Achieve Micron-Level Precision for Your Materials

- What is the preventive maintenance of ball mill? Ensure Maximum Uptime and Reliability

- Why are excellent sealing and corrosion resistance required for WC-10Co ball milling? Ensure High-Purity Mixing Results