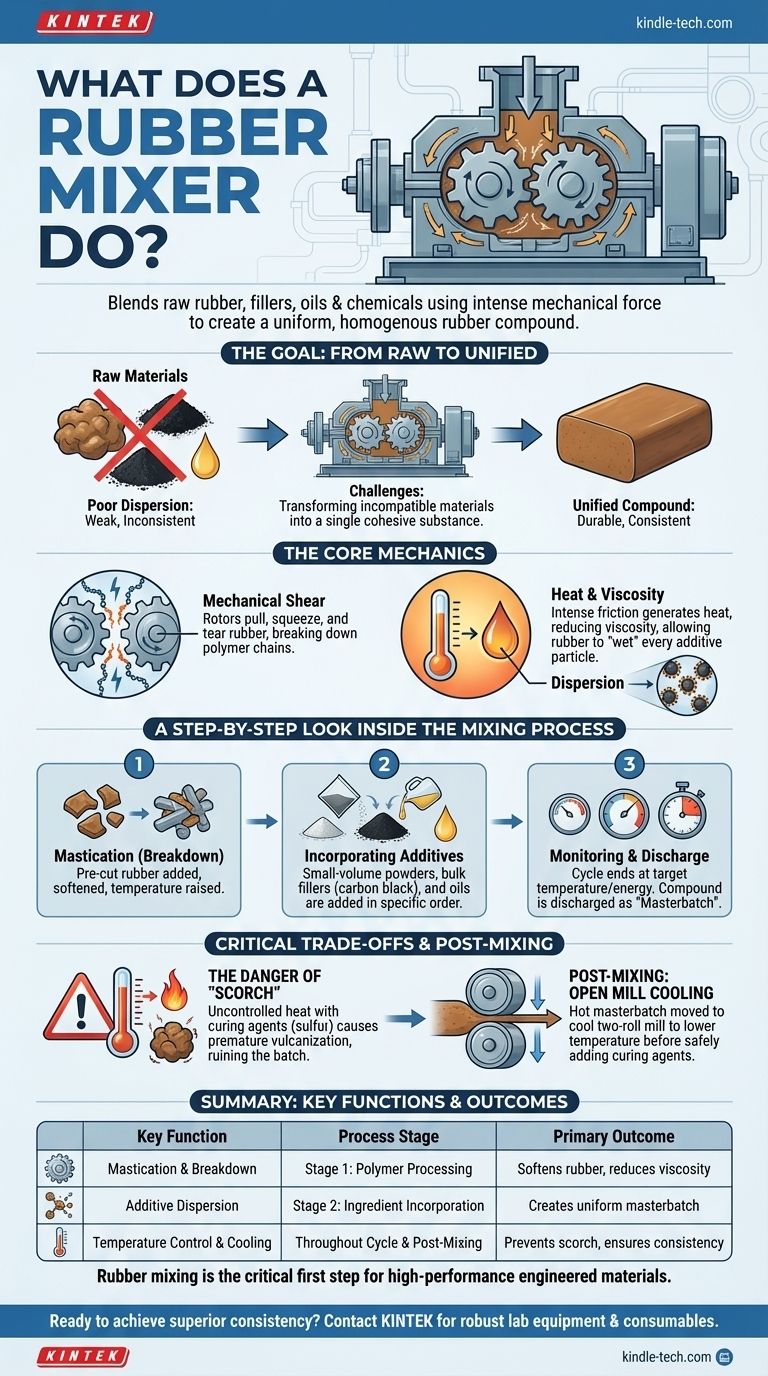

At its core, a rubber mixer is a heavy-duty industrial machine designed to blend raw rubber polymers with a variety of additives like fillers, oils, and chemicals. It uses intense mechanical force from internal rotors to break down the tough rubber and thoroughly disperse these ingredients, creating a uniform, homogenous material known as a rubber compound.

The purpose of a rubber mixer goes beyond simple blending. It fundamentally changes the rubber's physical properties, using heat and high-shear force to reduce its viscosity. This allows the liquid-like rubber to "wet" and completely encapsulate every particle of additive, which is the absolute foundation for a durable and consistent final product.

The Goal: From Raw Ingredients to a Unified Compound

The challenge in rubber production is transforming a pile of separate, incompatible materials—sticky raw rubber, fine black powders, and slick oils—into a single, cohesive substance with predictable engineering properties.

The Problem of Poor Dispersion

Simply stirring these ingredients together would result in a useless clump. The additives would be unevenly distributed, creating weak points and inconsistencies. The final product would fail under stress because its internal structure would not be uniform.

The Role of Mechanical Shear

An internal mixer solves this with two powerful, specially shaped rotors inside a closed chamber. As the rotors turn, they continuously pull, squeeze, and tear the rubber. This intense mechanical action, known as shearing, physically breaks down the tough polymer chains.

The Importance of Heat and Viscosity

This aggressive shearing action generates significant friction and heat. As the temperature of the rubber rises, its viscosity (resistance to flow) drops dramatically. The stiff, solid rubber becomes a thick, pliable mass.

This low-viscosity state is critical. It improves the wettability of the rubber, allowing it to flow around and coat the surface of every particle of compounding agent, ensuring no clumps of filler remain. This guarantees a truly uniform dispersion.

A Step-by-Step Look Inside the Mixing Process

The mixing process is a carefully controlled and timed sequence. The order in which ingredients are added is not arbitrary; it is engineered for optimal results.

Stage 1: Breaking Down the Polymer

First, pre-cut pieces of raw rubber are added to the pre-heated mixer. The rotors work on the rubber alone for a short period. This initial step, called mastication, breaks down the polymer's molecular structure and begins to raise its temperature.

Stage 2: Incorporating Additives

Once the rubber is softened, the other ingredients are added in a specific order. Small-volume powders (like protective antioxidants) are often added first, followed by bulk fillers like carbon black. Finally, liquid softeners and processing oils are introduced to complete the mixing cycle.

Stage 3: Monitoring the "Masterbatch"

Throughout this process, critical parameters are constantly monitored: mixing time, rotor speed, chamber pressure, and most importantly, temperature and power consumption. The cycle ends when the compound reaches a target temperature or energy level, indicating that dispersion is complete. The resulting compound is then discharged.

Understanding the Critical Trade-offs

The entire process is a balancing act, primarily revolving around temperature. While heat is necessary for mixing, uncontrolled heat can ruin the entire batch.

The Danger of "Scorch"

The one ingredient deliberately left out of the high-heat internal mixer is the curing agent, most commonly sulfur. If sulfur were present at the high temperatures inside the mixer, it would trigger vulcanization—the chemical process that permanently hardens rubber.

This premature hardening, known as scorch, would render the compound unusable, as it could no longer be shaped or molded.

The Post-Mixing Stage: Open Mill Processing

To avoid scorch, the hot batch of rubber (now called a "masterbatch") is discharged from the internal mixer and moved to a cooler, two-roll open mill. Here, the compound is passed through rollers to cool it down.

Only once the temperature is safely below a specific threshold (e.g., 110°C) is the sulfur added and gently blended in. The rubber is then sheeted, cooled, and stored for later use in molding or extrusion.

Making the Right Choice for Your Goal

Understanding this process is key to controlling the quality and performance of any rubber-based product.

- If your primary focus is material consistency: The rigorous control of the mixing cycle—time, temperature, and energy—is what ensures every batch has identical physical properties.

- If your primary focus is product durability: Proper dispersion of carbon black, achieved only through high-shear mixing, is what provides the finished product its strength, abrasion resistance, and toughness.

- If your primary focus is process efficiency: Separating the hot masterbatch mixing from the cool sulfur addition on an open mill is the fundamental technique for preventing costly, scrap-generating scorch.

Ultimately, the rubber mixer is the critical first step that transforms a simple list of ingredients into a complex, high-performance engineered material.

Summary Table:

| Key Function | Process Stage | Primary Outcome |

|---|---|---|

| Mastication & Breakdown | Stage 1: Polymer Processing | Softens rubber and reduces viscosity |

| Additive Dispersion | Stage 2: Ingredient Incorporation | Creates a uniform, homogenous masterbatch |

| Temperature & Energy Control | Throughout the Cycle | Prevents scorch and ensures batch consistency |

| Post-Mixing Cooling | Open Mill Processing | Safely incorporates curing agents like sulfur |

Ready to achieve superior material consistency and durability in your rubber production?

At KINTEK, we specialize in providing robust laboratory equipment and consumables for precise material testing and development. Whether you are optimizing your mixing cycle or scaling up production, our solutions help you ensure every batch meets your exact specifications.

Contact us today using the form below to discuss how our expertise can enhance your process efficiency and product quality.

Visual Guide

Related Products

- Laboratory Vortex Mixer Orbital Shaker Multifunctional Rotation Oscillation Mixer

- Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

- Laboratory Oscillating Orbital Shaker

- High Shear Homogenizer for Pharmaceutical and Cosmetic Applications

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

People Also Ask

- How does a laboratory stirrer influence MOF product quality? Master Precision in Non-Solvothermal Synthesis

- What is the primary purpose of using an orbital shaker during metal ion adsorption? Optimize PAF Performance

- What are the primary functions of a laboratory orbital shaker during BMP testing? Maximize Methane Yield Accuracy

- What is the function of a laboratory shaker during batch adsorption experiments? Optimize Fly Ash Kinetic Research

- What is the role of laboratory stirring equipment in nZVI preparation? Achieve Stable and Uniform Nano Slurries