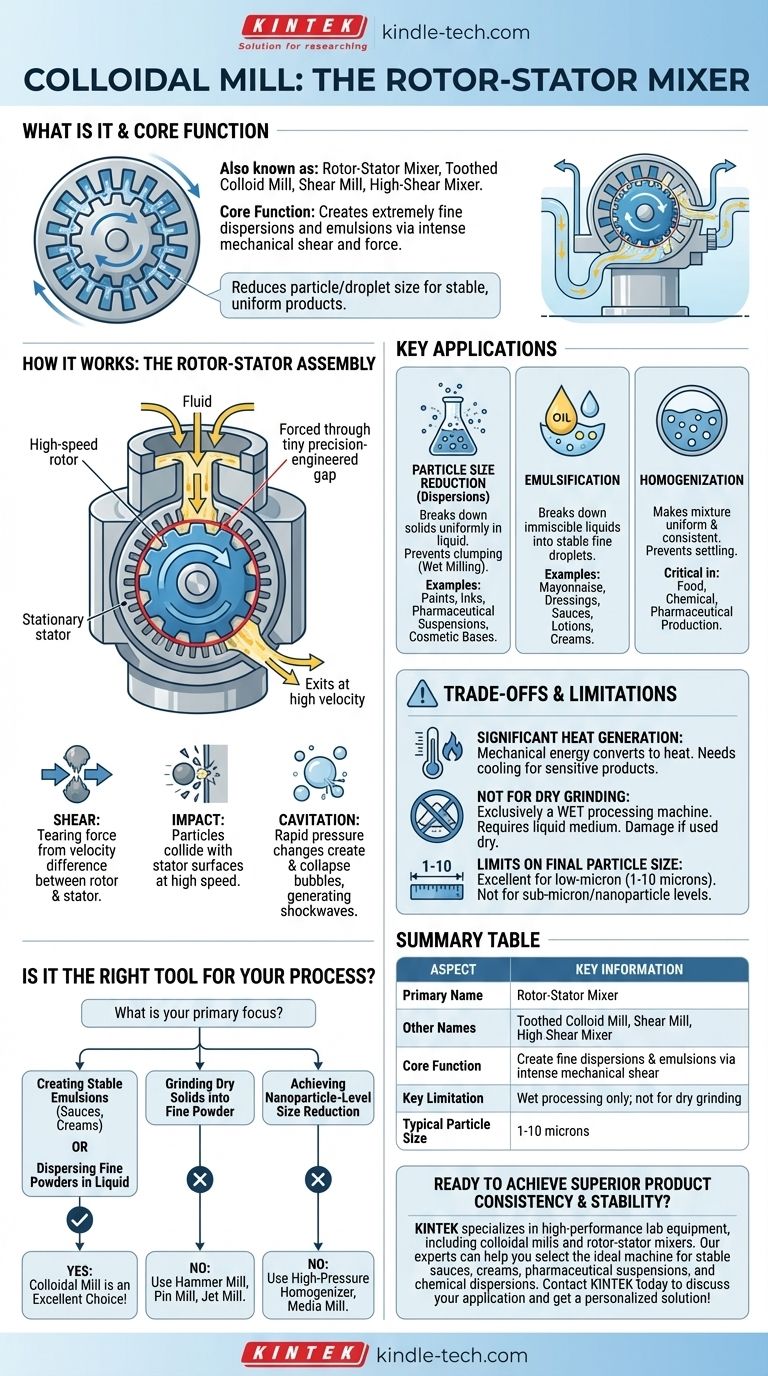

In technical and industrial settings, a colloidal mill is most frequently known as a rotor-stator mixer. Other common names you might encounter include a toothed colloid mill, a shear mill, or simply a high-shear mixer. While the names vary, they all describe a machine designed to create extremely fine dispersions and emulsions by subjecting fluids to intense mechanical force.

The core function of a colloidal mill is not simply to mix, but to violently shear liquid and suspended particles by forcing them through a tiny, precision-engineered gap between a high-speed rotor and a stationary stator. This action reduces particle or droplet size to create stable, uniform products.

How a Colloidal Mill Actually Works

To understand why this equipment is so effective, you need to look at its fundamental design. Its power comes from the precise interaction of two key components that generate forces far beyond what a conventional mixer can achieve.

The Rotor and Stator Assembly

The heart of the machine is the rotor-stator head. The rotor is a component that spins at very high speeds, typically several thousand RPM. The stator is the stationary component that closely surrounds the rotor.

Both the rotor and stator often have intricate patterns of teeth, slots, or holes. The design of these patterns is critical for the specific application, whether it's emulsifying, dispersing, or homogenizing.

Creating Intense Hydraulic Shear

The working principle relies on the extremely small clearance, or gap, between the spinning rotor and the fixed stator. As the fluid is fed into the assembly, the high-speed rotor acts as a centrifugal pump, drawing the material into the gap.

As the fluid is forced through this narrow space at high velocity, it experiences immense hydraulic shear. This is the primary force that rips apart particles, deagglomerates powders, and breaks down liquid droplets.

The Three Key Forces at Play

The size reduction process isn't just about one action. It's a combination of three powerful physical forces happening almost simultaneously within the rotor-stator head.

- Shear: As described, this is the tearing force created by the velocity difference between the rotor and stator surfaces.

- Impact: Particles are accelerated at high speed by the rotor and collide with the stationary stator surfaces, physically shattering them.

- Cavitation: The rapid pressure changes within the mixer can create and collapse microscopic vacuum bubbles. This collapse generates powerful shockwaves that further break down particles.

What is a Colloidal Mill Used For?

The mill's ability to generate these forces makes it indispensable in numerous industries for creating products with specific textures, stability, and performance characteristics.

Particle Size Reduction (Dispersions)

One of the main uses is to break down and disperse solid particles uniformly throughout a liquid base. This process, often called wet milling, prevents clumping (agglomeration) and ensures a smooth final product.

Common examples include dispersing pigments for paints and inks, creating pharmaceutical suspensions, or mixing active ingredients into cosmetic bases.

Emulsification

An emulsion is a mixture of two liquids that normally do not mix, like oil and water. A colloidal mill is exceptionally effective at breaking down droplets of one liquid and dispersing them finely within the other.

This creates stable emulsions like mayonnaise, salad dressings, sauces, lotions, and creams, preventing them from separating over time.

Homogenization

Homogenization is the process of making a mixture uniform and consistent. By drastically reducing the size of all particles or droplets in a fluid, the mill ensures that the final product has a smooth texture and that its components will not settle out. This is critical in food, chemical, and pharmaceutical production.

Understanding the Trade-offs and Limitations

While powerful, a colloidal mill is a specialized tool and not the solution for every processing challenge. Understanding its limitations is key to using it effectively.

Significant Heat Generation

The immense mechanical energy and friction generated by a high-shear mill are converted directly into heat. This can be a major issue for temperature-sensitive products like some pharmaceuticals or food items. Many industrial models incorporate a cooling jacket to manage this heat buildup.

Not for Dry Grinding

This is a critical distinction. A colloidal mill is exclusively a wet processing machine. It requires a liquid medium to function and cannot be used to grind dry powders or solids. Attempting to do so would damage the equipment and fail to produce the desired result.

Limits on Final Particle Size

A colloidal mill is excellent for reducing particles down to the low-micron range (typically 1-10 microns). However, it is generally not capable of achieving sub-micron or nanoparticle-level sizes. For that level of reduction, other equipment like high-pressure homogenizers or media mills (bead mills) are required.

Is a Colloidal Mill the Right Tool for Your Process?

Choosing the right processing equipment depends entirely on your raw materials and your desired final product characteristics.

- If your primary focus is creating stable emulsions like sauces or creams: A colloidal mill is an excellent choice due to its exceptional emulsifying capabilities.

- If your primary focus is dispersing fine powders into a liquid without clumps: This is a core strength of the rotor-stator design, making it a highly effective tool.

- If your primary focus is grinding dry solids into a fine powder: You must use a different type of equipment, such as a hammer mill, pin mill, or jet mill.

- If your primary focus is achieving true nanoparticle-level size reduction: You will need to look beyond a colloidal mill to more advanced technologies like a high-pressure homogenizer.

Ultimately, a colloidal mill excels at creating finely dispersed and uniform liquid mixtures by applying intense, localized mechanical force.

Summary Table:

| Aspect | Key Information |

|---|---|

| Primary Name | Rotor-Stator Mixer |

| Other Names | Toothed Colloid Mill, Shear Mill, High-Shear Mixer |

| Core Function | Create fine dispersions & emulsions via intense mechanical shear |

| Key Limitation | Wet processing only; not for dry grinding |

| Typical Particle Size | 1-10 microns |

Ready to achieve superior product consistency and stability?

KINTEK specializes in high-performance lab equipment, including colloidal mills and rotor-stator mixers, to meet your precise dispersion and emulsification needs. Our experts can help you select the ideal machine for creating stable sauces, creams, pharmaceutical suspensions, and chemical dispersions.

Contact KINTEK today to discuss your application and get a personalized solution!

Visual Guide

Related Products

- Laboratory Single Horizontal Jar Mill

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- High Energy Vibratory Laboratory Ball Mill Double Tank Type

- Open Type Two Roll Mixing Mill Machine for Rubber Crusher

- Laboratory Four-Body Horizontal Jar Mill

People Also Ask

- Why is a grinding mill necessary during cement clinker pulverization? Unlock Reactivity and Strength

- What is the primary function of the grinding process in NCM-811 & beta-Li3PS4 preparation? Optimize Battery Performance

- What are the advantages of using high-hardness steel balls as grinding media? Elevate Zirconium Hydride Synthesis

- What is use for grinding in the laboratory? Select the Right Mill for Accurate Sample Prep

- Why is it necessary to grind LAGP samples before XRD? Eliminate Preferred Orientation for Accurate Phase Analysis

- What role does a high-frequency ultrasonic homogenizer play in PEO? Achieve Superior Coating Uniformity and Stability

- What are the design advantages of the grinding chambers in jet mills? Achieve Ultra-Pure Size Reduction Without Wear

- What are laboratory mixers used for? Achieve Perfect Sample Homogeneity and Reliable Results