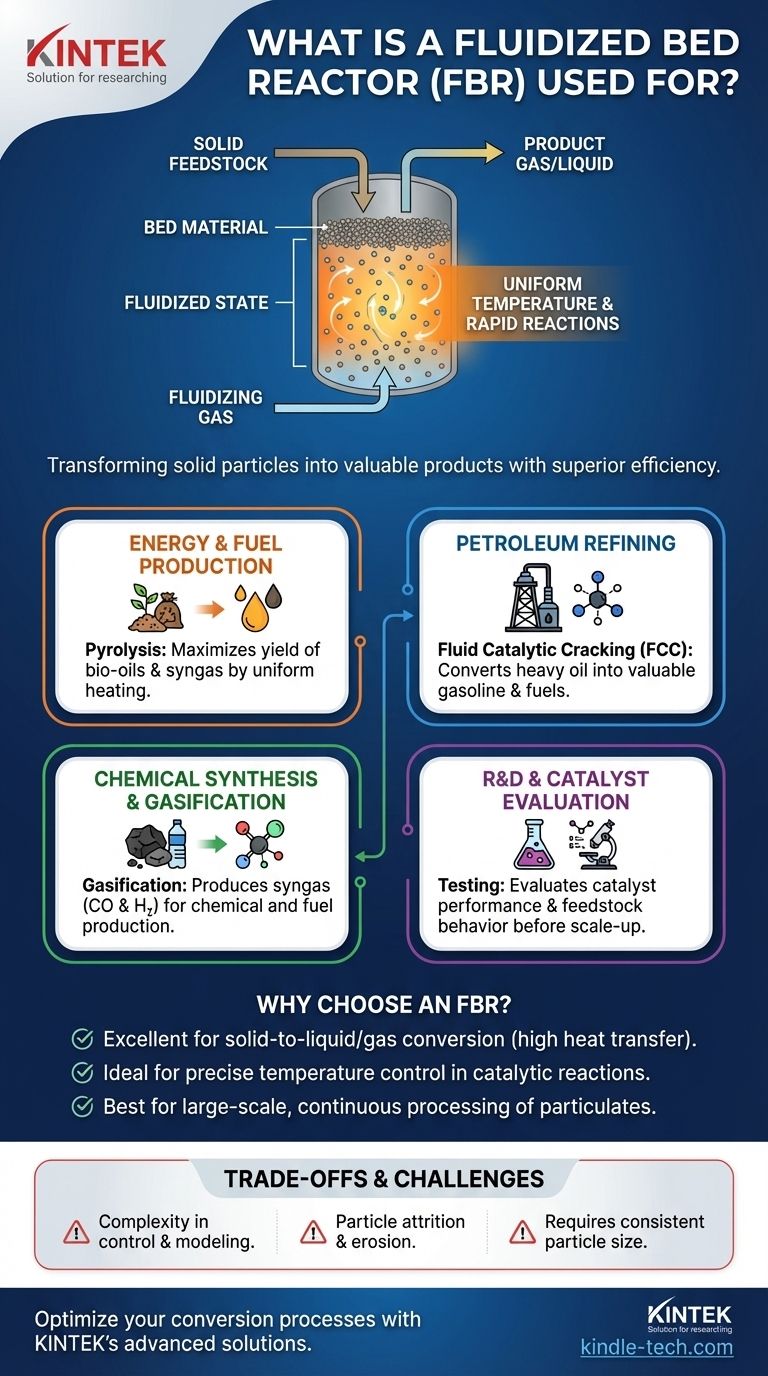

In essence, a fluidized bed reactor (FBR) is a powerful tool for transforming solid particles into valuable gases, liquids, and other chemical products. It is widely used in industries ranging from energy and petroleum refining to chemical synthesis for applications like the pyrolysis of biomass, fluid catalytic cracking (FCC) of heavy oils, and the gasification of coal or plastics.

The core advantage of a fluidized bed reactor is its ability to make a bed of solid particles behave like a well-mixed fluid. This unique state enables exceptionally uniform temperatures and rapid reactions that are difficult to achieve in other reactor types.

How a Fluidized Bed Reactor Works

To understand its applications, you must first grasp its fundamental operating principle. The reactor's design solves the classic engineering challenge of efficiently heating and reacting solid materials.

The Core Principle: Making Solids Behave Like a Fluid

An FBR contains a bed of granular material, such as sand or a catalyst. A gas or liquid is pumped upward through this bed from below.

At a specific velocity, this upward flow counteracts gravity just enough to suspend the particles, causing them to mix and circulate in a manner very similar to a boiling fluid. This is the "fluidized" state.

Superior Heat and Mass Transfer

This fluid-like behavior is the key to the FBR's effectiveness. The constant, vigorous mixing of particles ensures an almost perfectly uniform temperature throughout the entire reactor, eliminating dangerous hot spots or inefficient cold zones.

This also facilitates excellent contact between the reactant particles, the hot bed material, and any catalytic surfaces, dramatically accelerating the desired chemical reactions.

Key Components: Bed Material and Fluidizing Gas

The bed material (e.g., sand) typically acts as the primary heat carrier, efficiently transferring thermal energy to the feedstock being processed.

The fluidizing gas serves two purposes. First, it creates the fluidization itself. Second, it can be used to control the chemical environment. For example, using an inert gas like nitrogen prevents unwanted combustion or side-reactions during processes like pyrolysis.

Key Industrial Applications

The unique properties of an FBR make it the preferred choice for several large-scale industrial processes that involve solid feedstocks.

Energy and Fuel Production

FBRs are central to converting solid biomass, plastics, or waste into energy. In pyrolysis, the reactor's rapid and uniform heating maximizes the yield of valuable bio-oils and syngas by preventing the feedstock from charring excessively.

Petroleum Refining

The most prominent use in this sector is Fluid Catalytic Cracking (FCC). In an FCC unit, an FBR is used to "crack" large, low-value hydrocarbon molecules from crude oil into smaller, high-value molecules like gasoline.

Chemical Synthesis and Gasification

FBRs are used for gasification, a process that converts carbon-based materials like coal or organic waste into a mixture of gases called syngas (carbon monoxide and hydrogen). This syngas is a foundational building block for producing fuels and chemicals.

Catalyst and Feedstock Evaluation

On a smaller scale, labs use FBRs to test the performance and durability of new catalysts or to analyze how different feedstocks will behave under specific process conditions before scaling up to industrial production.

Understanding the Trade-offs

While powerful, the FBR is not a universal solution. Its advantages come with specific engineering challenges that must be managed.

Complexity and Control

The fluid dynamics inside an FBR are complex and can be difficult to model accurately. Maintaining the stable fluidized state requires precise control over gas velocity and particle size distribution.

Particle Attrition and Erosion

The constant, energetic motion of particles can cause them to break down over time, a process known as attrition. This same motion can also cause significant wear and erosion on the internal walls and components of the reactor.

Feedstock Limitations

FBRs work best with particulate substrates of a relatively consistent size and shape. They are not suitable for processing large, non-uniform chunks of material, which require significant pre-processing (grinding and sorting) to be used effectively.

When to Choose a Fluidized Bed Reactor

Selecting an FBR depends entirely on the specific goals of your chemical process and the nature of your feedstock.

- If your primary focus is efficiently converting solids into liquids or gases: The FBR is ideal due to its superior heat transfer, which maximizes the yield of desired products in processes like pyrolysis.

- If your primary focus is a catalytic reaction requiring precise temperature control: The FBR's uniform temperature profile prevents catalyst deactivation from hot spots and ensures consistent product quality.

- If your primary focus is large-scale, continuous processing of particulates: The FBR excels at handling high throughputs, making it a cornerstone technology in industries like petroleum refining.

Ultimately, the fluidized bed reactor excels wherever precise and uniform control over the transformation of solid particles is the critical factor for success.

Summary Table:

| Application | Key Process | Primary Benefit |

|---|---|---|

| Energy & Fuel Production | Biomass/Plastic Pyrolysis | Maximizes bio-oil & syngas yield |

| Petroleum Refining | Fluid Catalytic Cracking (FCC) | Converts heavy oil to gasoline |

| Chemical Synthesis | Coal/Plastic Gasification | Produces syngas for fuels & chemicals |

| R&D & Testing | Catalyst & Feedstock Evaluation | Tests performance before scaling up |

Ready to optimize your solid feedstock conversion processes? KINTEK specializes in advanced lab equipment, including reactors for pyrolysis, gasification, and catalytic testing. Our expertise helps you achieve uniform heating, rapid reactions, and maximum product yield. Contact our experts today to find the perfect solution for your laboratory's needs!

Visual Guide

Related Products

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

People Also Ask

- What is the role of high-pressure reactors in the study of alloy oxidation? Essential Tools for Supercritical Research

- How does a high-pressure reactor demonstrate its value in accelerated aging? Predict Catalyst Durability Fast

- Why are high-pressure autoclaves essential for preparing bio-based polyamide curing agents from dimeric acid?

- What is the purpose of using a high-temperature hydrothermal reactor? Enhance Iodine@Activated Carbon Cathode Synthesis

- What roles do autoclaves play in MFI zeolite synthesis? Master Hydrothermal Crystalline Growth