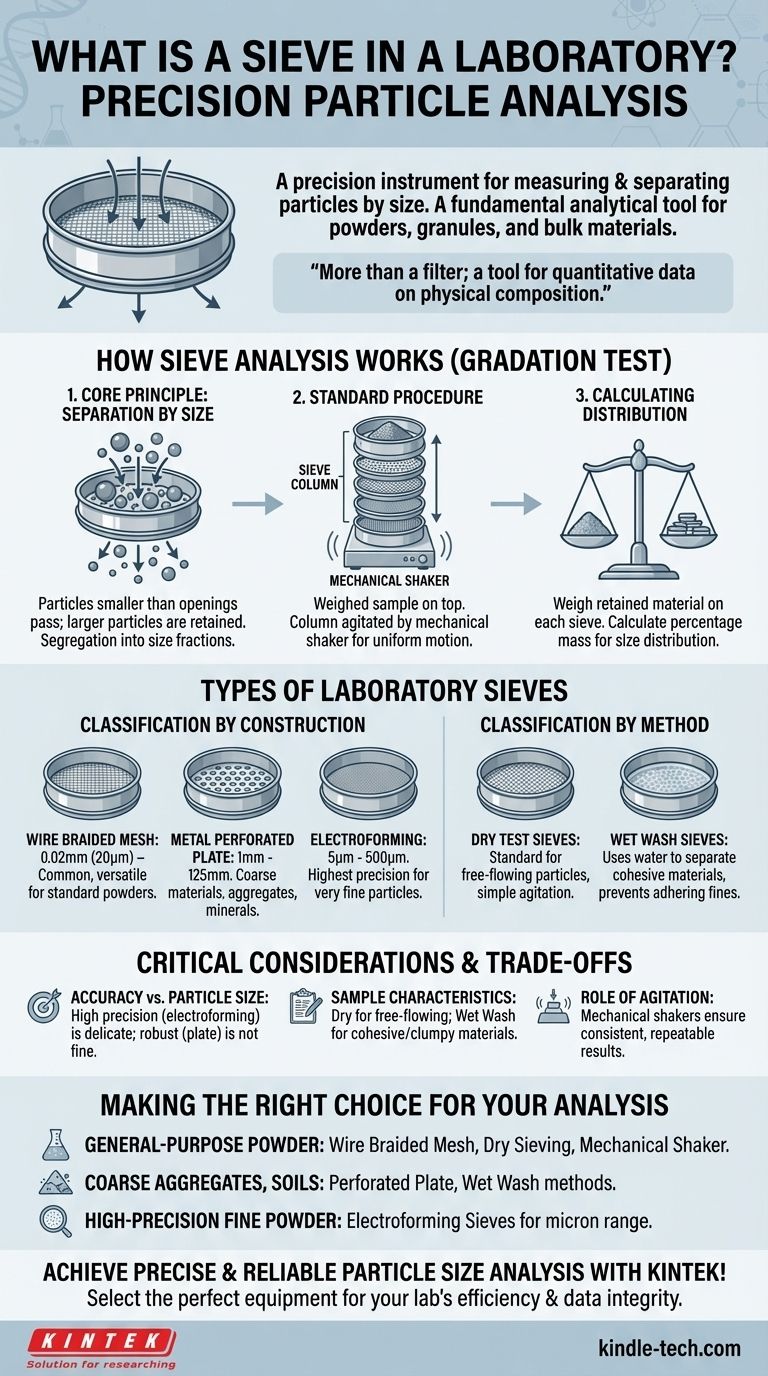

In any laboratory focused on physical materials, a sieve is a precision instrument used to measure and separate particles based on their size. It consists of a frame, typically circular, with a screen of a specific mesh or aperture size. By passing a sample through one or more of these sieves, analysts can accurately determine the particle size distribution of powders, granules, and other bulk materials.

A laboratory sieve is more than a simple filter; it is a fundamental analytical tool. Its primary purpose is to provide quantitative data on a material's physical composition by physically sorting particles through precisely calibrated openings.

How Sieve Analysis Works

Sieve analysis, also known as a gradation test, is a standardized procedure for assessing the particle size distribution of a granular material.

The Core Principle: Separation by Size

The entire process is based on a simple mechanical action. Particles smaller than the openings in the sieve screen pass through, while larger particles are retained on top.

This allows for the physical segregation of a sample into different size fractions.

The Standard Procedure

A representative, weighed sample is placed on the top sieve in a stack, or "column," of sieves. Each sieve in the column has progressively smaller openings than the one above it.

This column is placed on a mechanical shaker, which agitates the stack. This vibration ensures all particles have an opportunity to pass through the apertures if they are small enough.

Calculating the Distribution

After shaking is complete, the material retained on each individual sieve is weighed.

The mass of the material on each sieve is then divided by the total initial mass. This calculation reveals the percentage of the sample that falls within each specific size range, providing a clear picture of the material's particle size distribution.

Understanding the Types of Laboratory Sieves

Sieves are not a one-size-fits-all tool. They are categorized by their construction and the method in which they are used, each designed for different materials and levels of precision.

Classification by Construction

- Wire Braided Mesh Sieves: These are the most common type, used for a wide range of particle sizes, typically from 0.02mm (20 microns) up to 2.36mm. They are versatile for many standard powders and fine granules.

- Metal Perforated Plate Sieves: For analyzing larger, coarser materials, these sieves use a metal plate with precisely punched holes. They cover a size range from 1mm up to 125mm and are common in aggregate and mineral analysis.

- Electroforming Sieves: Offering the highest level of precision, these sieves are created through an electro-deposition process. They are used for very fine particles, from 5µm to 500µm, where extreme accuracy is required.

Classification by Method

- Dry Test Sieves: This is the standard method for free-flowing particles that can easily pass through the sieve openings with simple agitation or tapping.

- Wet Wash Sieves: This technique is employed when water is needed to help particles pass through the mesh. It is essential for materials where fine particles, like dirt or silt, adhere to larger particles, which would otherwise skew the results.

Critical Considerations and Trade-offs

Choosing the correct sieve and method is fundamental to achieving accurate and repeatable results. Simply owning a set of sieves is not enough.

Accuracy vs. Particle Size

The required precision of your analysis dictates the type of sieve you must use. Electroforming sieves provide unparalleled accuracy for micro-particles, but they are delicate and expensive. Perforated plate sieves are robust for large materials but are not suitable for fine powder analysis.

Sample Characteristics Matter

The nature of your sample material is a critical factor. A dry, free-flowing powder is ideal for standard dry sieving. However, cohesive, clumpy, or dirty materials will require wet wash sieving to ensure fine particles are properly washed through the screen for an accurate measurement.

The Role of Agitation

The results of a sieve analysis are highly dependent on the consistency of the shaking process. A mechanical shaker provides a repeatable, uniform motion that cannot be achieved by hand, ensuring that results are comparable between different tests and different labs.

Making the Right Choice for Your Analysis

Your analytical goal determines the ideal equipment and methodology.

- If your primary focus is general-purpose powder analysis: A standard set of wire braided mesh sieves paired with a mechanical shaker for dry sieving is the most effective starting point.

- If your primary focus is coarse aggregates, soils, or minerals: You will require durable perforated plate sieves and should consider wet wash methods to clean samples for accurate sizing.

- If your primary focus is high-precision analysis of very fine powders: Specialized electroforming sieves are necessary to achieve the accuracy required for particles in the micron range.

Ultimately, selecting the correct sieve is the foundational step for reliable and insightful material characterization.

Summary Table:

| Sieve Type | Typical Size Range | Best For |

|---|---|---|

| Wire Braided Mesh | 0.02mm (20µm) - 2.36mm | General-purpose powder analysis |

| Metal Perforated Plate | 1mm - 125mm | Coarse aggregates, soils, minerals |

| Electroforming | 5µm - 500µm | High-precision analysis of fine powders |

Ready to achieve precise and reliable particle size analysis?

The right sieve is the foundation of accurate material characterization. At KINTEK, we specialize in providing high-quality laboratory sieves and equipment tailored to your specific needs—whether you're analyzing fine powders, coarse aggregates, or require high-precision electroforming sieves.

Let our experts help you select the perfect equipment to ensure your lab's efficiency and data integrity. Contact KINTEK today for a consultation and elevate your analytical capabilities!

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Three-dimensional electromagnetic sieving instrument

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Wet Three-Dimensional Vibratory Sieve Shaker Machine

- Laboratory Multifunctional Small Speed-Adjustable Horizontal Mechanical Shaker for Lab

People Also Ask

- What is the importance of sieving in chemistry? Master Particle Size for Precise Control

- How can we separate different sized particles by sieving? A Guide to Accurate Particle Size Distribution

- Why is an industrial-grade standard sieve used after catalyst regeneration? Ensure Purity & Physical Integrity

- How do we select a sieve? A Systems-Based Guide to Accurate Particle Separation

- What is the process of sieve analysis? A Step-by-Step Guide to Particle Size Distribution

- Why is sieve analysis important in construction industry? Ensure Material Strength & Cost-Efficiency

- Can sieving be used to separate a solid substance from a liquid substance? Learn the Right Technique for Your Mixture

- What is the primary purpose of using laboratory standard sieves? Optimize Composting Pre-treatment for Pig Manure