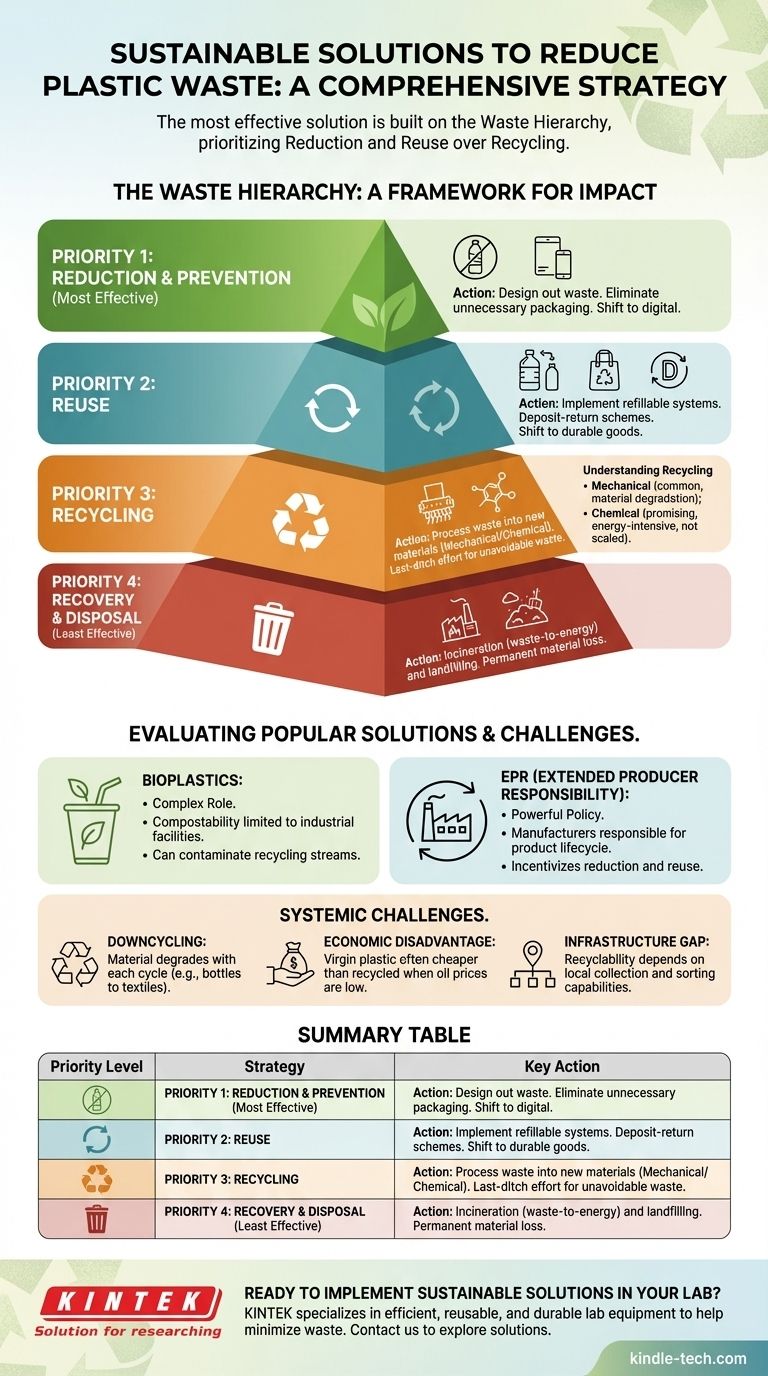

While no single technology offers a magic bullet, the most effective and sustainable solution to reduce plastic waste is a comprehensive strategy built on the Waste Hierarchy. This framework prioritizes actions in order of environmental impact, placing the greatest emphasis on Reduction and Reuse long before considering recycling. This approach tackles the problem at its source, rather than just managing the symptoms.

The critical mistake is focusing on recycling as the primary solution. True sustainability is achieved by fundamentally rethinking design, consumption, and policy to eliminate the need for single-use plastics from the very beginning.

The Foundation: Understanding the Waste Hierarchy

The Waste Hierarchy is a universally accepted framework that guides sustainable waste management. It ranks waste management options from most to least preferable, forcing a shift in focus from downstream problems (like recycling) to upstream solutions (like prevention).

Priority 1: Reduction and Prevention

This is the single most impactful step. The most sustainable plastic is the one that is never created.

Reduction involves designing systems and products that require less material or no plastic at all. This includes eliminating unnecessary packaging, "light-weighting" essential products, and shifting to digital alternatives.

Priority 2: Reuse

If plastic cannot be eliminated, the next best option is to keep it in use for as long as possible in its original form.

Reuse systems, such as refillable containers for beverages and cleaning products or deposit-return schemes, preserve the material's value and significantly reduce the energy and resources needed to create new items. It represents a shift from a disposable to a durable mindset.

Priority 3: Recycling

Recycling is the process of recovering scrap or waste plastic and reprocessing it into new products. It is a crucial part of the solution, but it is the third-best option for a reason.

While it diverts material from landfills, the process has significant limitations, including energy consumption, material degradation, and contamination issues. It should be seen as a last-ditch effort for items that cannot be eliminated or reused.

The Last Resort: Recovery and Disposal

This tier includes processes like waste-to-energy incineration and, least desirably, landfilling. These options are reserved for waste that cannot be prevented, reused, or recycled and result in the permanent loss of material resources.

Evaluating Popular "Solutions" Through This Lens

Many proposed solutions gain media attention, but their true sustainability can be evaluated using the Waste Hierarchy.

The Role of Bioplastics

Bioplastics are often presented as a simple fix, but their role is complex. Some are designed to be compostable, but only in industrial facilities, not in a backyard bin or the open environment.

Furthermore, their production can have its own environmental footprint related to land and water use. If they enter conventional plastic recycling streams, they act as a contaminant, potentially ruining entire batches of recyclable material.

The Power of Extended Producer Responsibility (EPR)

EPR is a policy approach that makes manufacturers responsible for the entire lifecycle of their products, including their collection and final disposal.

This is a powerful lever for Reduction and Reuse. When companies bear the financial cost of their packaging waste, they are directly incentivized to design products that are lighter, easier to reuse, and more efficiently recycled.

Chemical vs. Mechanical Recycling

Mechanical recycling, the most common type, involves shredding, washing, melting, and reforming plastic. Chemical recycling (or "advanced recycling") uses various processes to break plastics down into their original molecular building blocks, which can then be used to create new, virgin-quality plastics.

While chemical recycling holds promise for handling hard-to-recycle mixed plastics, it is currently very energy-intensive, often has low yields, and is not yet proven at a large, economically viable scale.

Understanding the Trade-offs and Systemic Challenges

Achieving a circular economy for plastics requires acknowledging the significant hurdles that exist within the current system.

The Myth of Infinite Recyclability

Most common plastics cannot be recycled endlessly. The process of melting and reforming plastic degrades the polymer chains, a phenomenon known as downcycling.

After a few cycles, the material loses its structural integrity and must be used for lower-quality products (e.g., plastic bottles become textiles or lumber) until it is eventually landfilled or incinerated.

The Economic Disadvantage

Recycled plastic must compete with virgin plastic, which is produced directly from fossil fuels. When oil prices are low, virgin plastic is often cheaper and higher quality than its recycled counterpart, creating a poor economic incentive for manufacturers to use recycled content.

The Infrastructure Gap

A product's recyclability is meaningless without the local infrastructure to collect, sort, and process it. The availability and capability of recycling facilities vary dramatically between municipalities and countries, leading to widespread consumer confusion and low actual recycling rates.

Making the Right Choice for Your Goal

To effectively contribute to the solution, your actions must align with the Waste Hierarchy.

- If you are a product designer or business leader: Your primary focus should be on designing out waste from the start by exploring plastic-free materials and investing in robust reuse and refill systems.

- If you are a policymaker: Prioritize legislation like Extended Producer Responsibility (EPR) and provide funding for reuse infrastructure, which creates upstream incentives to reduce waste.

- If you are an individual consumer: Your greatest power lies in reducing consumption of single-use items and actively choosing reusable alternatives, making recycling your last option, not your first.

A sustainable future for plastics is achieved not by managing waste better, but by creating an economic and social system that doesn't produce it in the first place.

Summary Table:

| Priority Level | Strategy | Key Action |

|---|---|---|

| 1 (Most Effective) | Reduction & Prevention | Design out waste, eliminate unnecessary packaging |

| 2 | Reuse | Implement refillable systems, deposit-return schemes |

| 3 | Recycling | Process waste into new materials (mechanical/chemical) |

| 4 (Least Effective) | Recovery & Disposal | Incineration, landfilling as last resort |

Ready to implement sustainable solutions in your lab? KINTEK specializes in lab equipment and consumables, helping laboratories minimize waste through efficient, reusable, and durable products. Let us support your sustainability goals—contact our experts today to explore how our solutions can reduce your environmental impact while maintaining high performance.

Visual Guide

Related Products

- Aluminum-Plastic Flexible Packaging Film for Lithium Battery Packaging

- Custom Machined and Molded PTFE Teflon Parts Manufacturer for Laboratory ITO FTO Conductive Glass Cleaning Flower Basket

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Custom PTFE Teflon Parts Manufacturer for Cleaning Racks

- Wall Mounted Water Distillation Unit

People Also Ask

- What is the difference between RF sputtering and DC sputtering? Choose the Right Method for Your Material

- What is the alternative to brazing? Compare Welding, Soldering & Mechanical Fastening

- Why is Alumina Added in SHS Chromo-Aluminizing? Optimize Combustion & Coating Stability

- What is the principle of rota evaporation? A Guide to Gentle, Efficient Solvent Separation

- Why are stainless steel containers used for lithium melt modification? Ensure Purity and Corrosion Resistance

- What are some of the limitations of powder metallurgy technique? Understanding Part Size, Complexity, and Strength Constraints

- How does a sputtering system work? Achieve Superior Thin-Film Deposition for Your Lab

- What are the different types of biomass pellets? A Guide to Wood vs. Agricultural Pellets