In short, an attritor is a high-energy grinding mill used to reduce the size of particles in a slurry down to the sub-micron or even nanometer range. It is also used to create extremely fine and stable dispersions. Unlike a traditional ball mill that tumbles, an attritor uses a rotating internal shaft with arms to vigorously agitate grinding media, resulting in a much faster and more efficient process.

The core purpose of an attritor is not just to grind materials, but to do so with exceptional speed and energy. This makes it the preferred tool for applications demanding ultra-fine particles and highly stable dispersions, which are often unachievable with lower-energy methods.

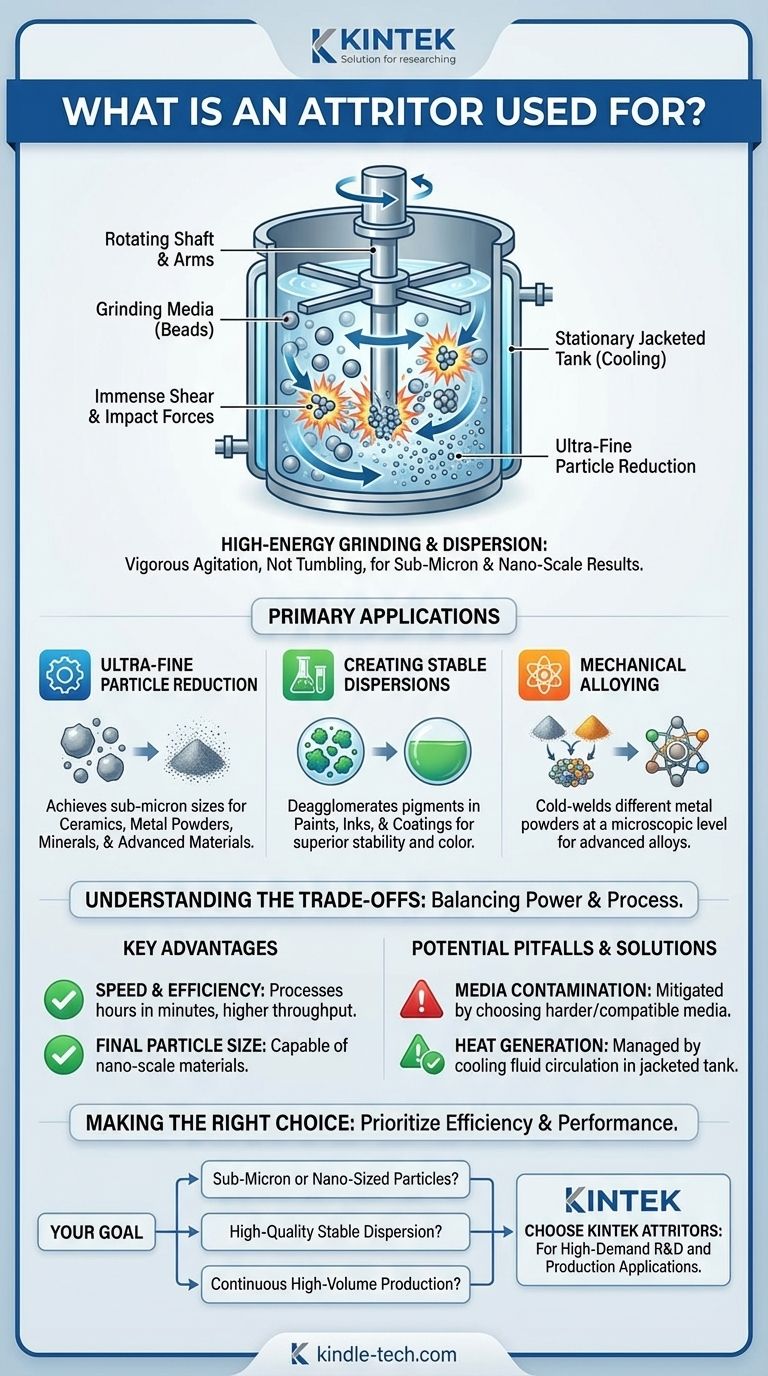

How an Attritor Achieves High-Energy Grinding

The effectiveness of an attritor lies in its unique design, which maximizes the energy transferred to the material being processed. It is fundamentally different from a simple tumbling ball mill.

The Core Components

An attritor consists of a stationary, jacketed tank filled with small, hard grinding media (such as ceramic or steel beads). Inside this tank, a central shaft with several projecting arms rotates at high speed.

The Grinding Action: Shear and Impact

As the shaft rotates, its arms agitate the grinding media at high velocity. The material, which is in a liquid slurry, is caught between the colliding beads. This action creates immense shear and impact forces that rapidly break down particles and tear apart agglomerates.

A Simple Analogy

Imagine a blender filled not just with liquid, but also with thousands of tiny, heavy marbles. When you turn it on, the blades (the attritor arms) don't just stir the liquid; they violently churn the marbles, which then pulverize anything caught between them.

Primary Applications: From Pigments to Advanced Alloys

The high-energy environment inside an attritor makes it suitable for a range of demanding industrial and research applications.

Ultra-Fine Particle Size Reduction

This is the most common use. Attritors excel at grinding materials down to one micron or less. This is critical for industries producing advanced ceramics, metal powders, minerals, sulfur for agricultural products, and high-performance fillers.

Creating Stable Dispersions

For products like paints, inks, and coatings, ensuring that pigment particles are broken down and evenly distributed is essential for color strength, gloss, and stability. An attritor's high shear is perfect for deagglomerating these fine powders into a liquid base.

Mechanical Alloying

In materials science, an attritor can be used for mechanical alloying. By grinding different metal powders together with sufficient force, the particles repeatedly fracture and cold-weld, creating a true alloy at a microscopic level without melting the materials.

Understanding the Trade-offs

While powerful, an attritor is not a universal solution. Understanding its advantages and limitations is key to using it effectively.

Key Advantage: Speed and Efficiency

The primary benefit is speed. A grinding or dispersion process that might take 24 hours in a traditional ball mill can often be completed in just one or two hours in an attritor. This dramatically increases throughput.

Key Advantage: Final Particle Size

Because of the high energy input, attritors can achieve much finer particle sizes than most other milling equipment, regularly producing nano-scale materials.

Potential Pitfall: Media Contamination

The constant, high-energy collision of the grinding media causes wear. Over time, trace amounts of the media material can be introduced into your product. This can be mitigated by choosing a media material (e.g., yttria-stabilized zirconia) that is harder than the material being ground or is chemically acceptable in the final product.

Potential Pitfall: Heat Generation

All of the energy put into the mill is eventually converted to heat. The stationary, jacketed tank is a critical feature, allowing for circulation of a cooling fluid (like water) to maintain a stable processing temperature and protect heat-sensitive materials.

Making the Right Choice for Your Goal

Selecting the correct milling strategy depends entirely on your end goal. The attritor is a specialized tool for high-demand applications.

- If your primary focus is simple lab-scale grinding of non-critical materials: A basic ball mill may be a more cost-effective starting point.

- If your primary focus is achieving sub-micron or nano-sized particles: An attritor is one of the most effective and efficient tools for the job.

- If your primary focus is creating a high-quality, stable dispersion for paints or inks: The high-shear action of an attritor is ideal for breaking up stubborn agglomerates.

- If your primary focus is producing large volumes continuously: A continuous or circulation attritor system is designed specifically for high-throughput manufacturing.

Ultimately, choosing an attritor is a decision to prioritize efficiency and the ability to produce extremely fine particles for high-performance applications.

Summary Table:

| Application | Key Benefit |

|---|---|

| Ultra-Fine Particle Size Reduction | Achieves sub-micron or nanometer particle sizes for ceramics, metal powders, and minerals. |

| Creating Stable Dispersions | High-shear action ideal for deagglomerating pigments in paints, inks, and coatings. |

| Mechanical Alloying | Creates true alloys at a microscopic level by cold-welding different metal powders. |

| Speed & Efficiency | Processes that take hours in a ball mill are completed much faster, increasing throughput. |

Ready to enhance your lab's capabilities with high-energy grinding?

An attritor from KINTEK is the key to unlocking superior efficiency and achieving the ultra-fine particle sizes required for your high-performance applications in advanced ceramics, metal powders, paints, inks, and materials science research.

Our experts will help you select the perfect attritor system to meet your specific goals, whether for R&D or high-volume production.

Contact KINTEK today to discuss your project and discover how our lab equipment can drive your success!

Visual Guide

Related Products

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Laboratory Single Horizontal Jar Mill

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- Laboratory Four-Body Horizontal Jar Mill

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

People Also Ask

- What are the factors affecting grinding efficiency? Optimize Your Process for Maximum Output

- What is the purpose of ball milling? A Versatile Tool for Material Synthesis and Modification

- What is the average speed of a ball mill? Optimize Grinding with Critical Speed Calculations

- What is the difference between a ball mill and a sag mill? A Guide to Primary vs. Secondary Grinding

- What affects ball mill efficiency? Optimize Grinding Speed, Media, and Material for Peak Performance