A classic example of autoclave use in a laboratory is the sterilization of glassware, such as flasks and beakers, before they are used to prepare sterile nutrient media for cell cultures. The autoclave uses high-pressure steam at a temperature of 121°C (250°F) or higher to eliminate all forms of microbial life, including bacteria, viruses, fungi, and resilient spores. This ensures that the scientific experiment begins with a completely sterile environment, free from outside contamination.

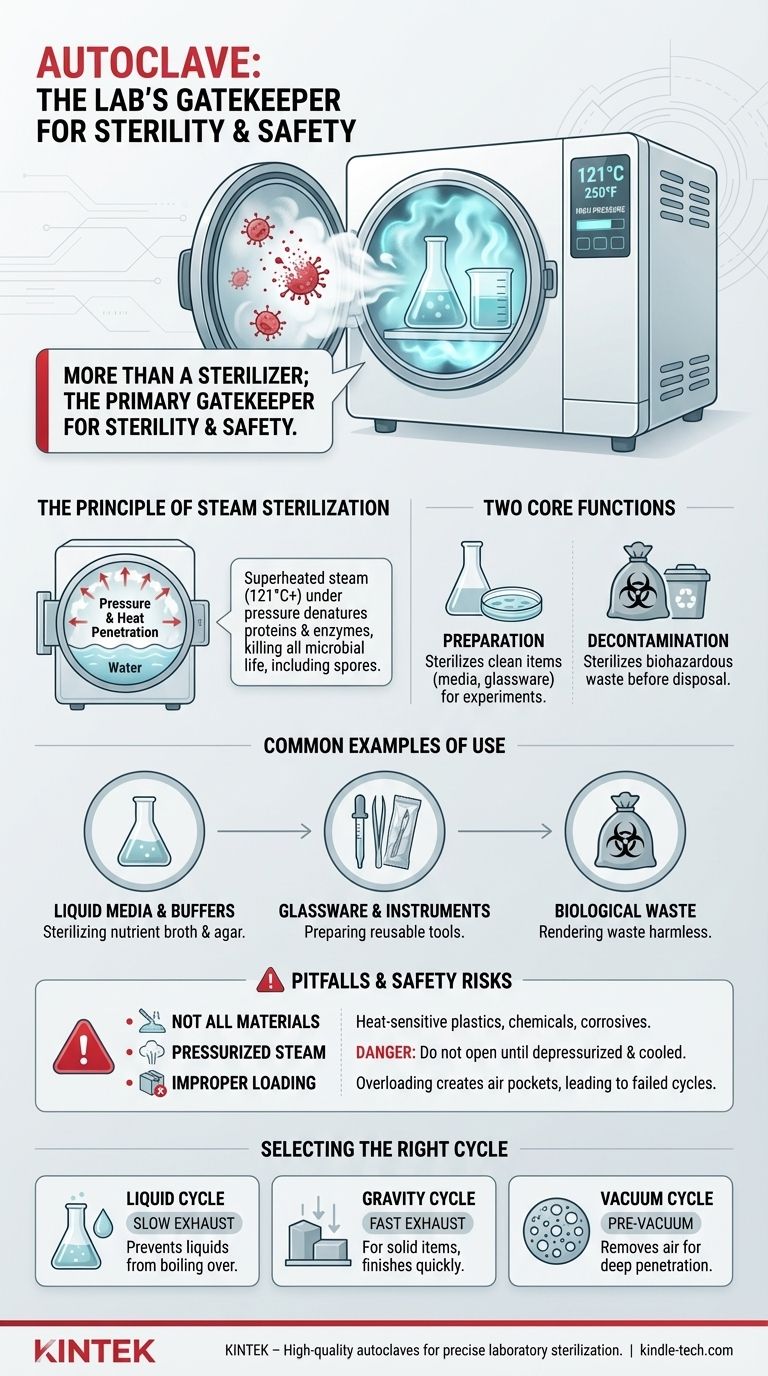

An autoclave is more than a simple sterilizer; it is the laboratory's primary gatekeeper for sterility and safety. It serves the dual purpose of preparing clean materials for experiments and decontaminating hazardous biological waste before disposal, making its correct operation fundamental to reliable science.

What an Autoclave Is and Why It's Essential

At its core, an autoclave is a pressure chamber that functions like a sophisticated pressure cooker. It is not the heat alone that sterilizes but the combination of heat and high-pressure steam, which is far more effective at penetrating materials and killing microorganisms.

The Principle of Steam Sterilization

The intense pressure inside an autoclave allows water to remain liquid at temperatures well above its normal boiling point. This superheated steam forcibly penetrates materials and transfers heat efficiently.

This process irreversibly denatures the essential proteins and enzymes within microbial cells, effectively killing them. It is considered the gold standard for sterilization because it is lethal to all forms of life, including heat-resistant bacterial spores that can survive simple boiling.

The Two Core Functions in a Lab

An autoclave performs two critical, opposite functions:

- Preparation: It sterilizes clean items (media, glassware, tools) to prevent contamination of sensitive experiments.

- Decontamination: It sterilizes used or contaminated items (biohazardous waste, used petri dishes) to make them safe for disposal.

Common Examples of Autoclave Use in the Lab

While the principle is simple, the applications are diverse and crucial for daily laboratory operations. A single lab may run its autoclave multiple times a day for different purposes.

Sterilizing Liquid Media and Buffers

Before growing bacteria or cell cultures, the liquid nutrient broth or agar media must be completely sterile. Autoclaves are used to sterilize these solutions in flasks and bottles, ensuring no unwanted microbes compete with the organism being studied.

Preparing Glassware and Instruments

Any reusable item that comes into contact with a sterile culture must first be sterilized. This includes glass pipettes, flasks, test tubes, and metal instruments like forceps and scalpels. These are often loosely capped or wrapped in foil to maintain sterility after the cycle is complete.

Decontaminating Biological Waste

After an experiment, all materials containing microorganisms, such as used petri dishes, culture tubes, and disposable plasticware, are considered biohazards. These materials are collected in special autoclave-safe bags and sterilized to render them harmless before they are discarded as regular waste.

Understanding the Pitfalls and Safety Risks

While highly effective, an autoclave is a powerful piece of equipment that demands respect and proper procedure. Misuse can lead to failed sterilization or serious injury.

Not All Materials Are Autoclavable

You cannot autoclave heat-sensitive materials. This includes most standard plastics (which will melt), flammable or volatile chemicals (which can create explosive conditions), and certain corrosive substances. Always verify that an item is rated as "autoclavable."

The Danger of Pressurized Steam

The single greatest safety risk is opening the door before the chamber has fully cooled and depressurized. This can cause a violent release of scalding steam and can cause liquids inside to boil over explosively. Modern autoclaves have safety interlocks to prevent this, but vigilance is crucial.

Failed Sterilization from Improper Loading

Simply placing items inside is not enough. The steam must be able to circulate freely and contact every surface. Overloading the chamber or packing items too tightly creates air pockets that insulate contaminants from the steam, leading to an incomplete and failed sterilization cycle.

Making the Right Choice for Your Application

To use an autoclave effectively, you must select the correct cycle based on the material you are processing. The primary difference is how air is removed and how pressure is released.

- If your primary focus is sterilizing liquids (like media): Use a "liquid" or "slow exhaust" cycle. This prevents the liquids from boiling over as the chamber slowly depressurizes.

- If your primary focus is sterilizing solid items (like glassware or waste): Use a "gravity" or "fast exhaust" cycle. Steam displaces the air, and the cycle finishes quickly.

- If your primary focus is sterilizing porous items (like animal cages or wrapped surgical kits): Use a "vacuum" or "pre-vac" cycle. A vacuum pump actively removes air before steam is introduced, ensuring deep penetration.

Mastering the autoclave is a foundational skill for ensuring the safety, integrity, and reproducibility of your scientific work.

Summary Table:

| Application | Purpose | Example Items |

|---|---|---|

| Preparation | Sterilize clean items for experiments | Glassware, nutrient media, surgical tools |

| Decontamination | Sterilize hazardous waste for safe disposal | Used petri dishes, culture tubes, biohazard bags |

| Cycle Type | Best For | Key Feature |

| Liquid Cycle | Sterilizing liquids without boiling over | Slow exhaust to prevent spills |

| Gravity Cycle | Sterilizing solid items quickly | Fast exhaust for efficiency |

| Vacuum Cycle | Sterilizing porous or wrapped items | Pre-vacuum for deep steam penetration |

Ensure the integrity and safety of your laboratory work with the right autoclave.

KINTEK specializes in providing high-quality laboratory equipment, including a range of reliable autoclaves designed for precise sterilization of media, glassware, and biohazardous waste. Whether you are setting up a new lab or upgrading your current capabilities, our experts can help you select the perfect autoclave to meet your specific application needs—from liquid cycles for media preparation to vacuum cycles for complex loads.

Contact KINTEK today to discuss your laboratory's sterilization requirements and discover how our solutions can enhance your research reproducibility and safety.

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Laboratory Sterilizer Lab Autoclave Pulsating Vacuum Desktop Steam Sterilizer

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

People Also Ask

- Why is a high-pressure stainless steel autoclave with a PTFE liner required for N/TiO2-x synthesis? Expert Insights

- Why is a high-pressure hydrothermal synthesis autoclave necessary for MnO2 nanowires? Precision Catalyst Growth

- What is the pressure required in an autoclave? Achieve Sterile Results with 15 PSI

- What are the safety concerns when autoclaving? A Guide to Preventing Burns, Explosions, and Biohazards

- What is the most common machine used to sterilize medical supplies? The Definitive Guide to Autoclaves

- What is the size of the autoclave? Choose the Right Capacity for Your Lab

- What is the difference between an autoclave and a sterilizer? Understanding Sterilization Methods

- What is a "standard load" in the context of autoclave load validation? Define Your Sterilization Ceiling