At its core, cool grinding is a size-reduction process that uses cryogenic temperatures to alter a material's physical properties, making it easier to mill while preserving its quality. Also known as cryogenic grinding, the technique involves chilling a substance with agents like liquid nitrogen or carbon dioxide, which causes it to become hard and brittle.

The critical insight is that cool grinding isn't just about preventing heat damage. It fundamentally changes a material from being ductile and tough to being glass-like and brittle, enabling efficient grinding of substances that are otherwise impossible to process at ambient temperatures.

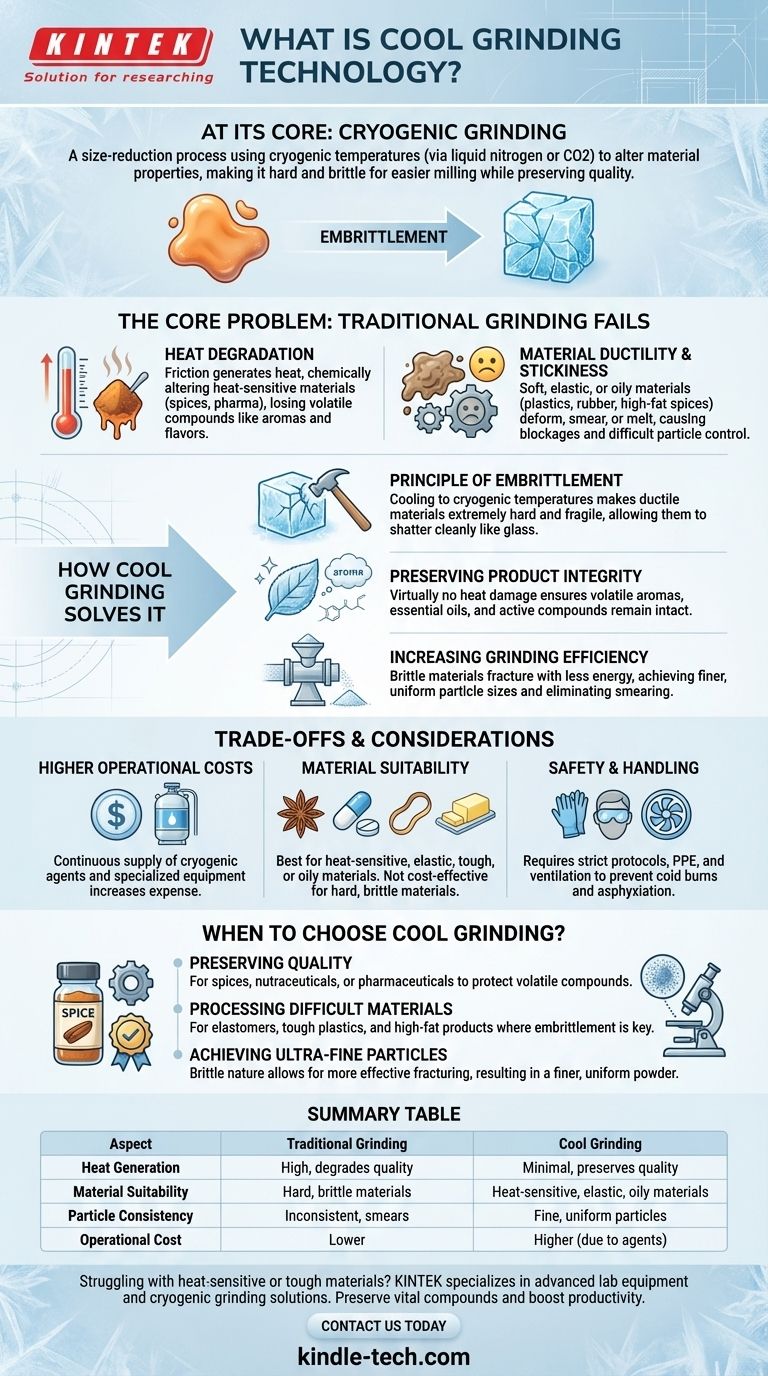

The Core Problem: Why Traditional Grinding Fails

Traditional grinding methods generate significant friction and heat. For many materials, this presents insurmountable challenges that degrade product quality and damage equipment.

Heat Degradation

Heat-sensitive materials, such as spices, pharmaceuticals, and certain polymers, can be chemically altered by the temperatures produced during ambient grinding.

This can result in the loss of volatile compounds, like aromas and flavors, or the degradation of active pharmaceutical ingredients (APIs).

Material Ductility and Stickiness

Soft, elastic, or oily materials (like plastics, rubbers, or high-fat spices) tend to deform, smear, or melt under the pressure and heat of a conventional mill.

This not only makes achieving a fine, consistent particle size difficult but also leads to equipment fouling, causing blockages and significant downtime for cleaning.

How Cool Grinding Solves the Problem

By introducing extreme cold into the process, cool grinding directly counteracts the primary failures of traditional methods.

The Principle of Embrittlement

The fundamental mechanism is embrittlement. When a material is cooled to cryogenic temperatures, its properties change on a molecular level.

Ductile materials that would typically bend or stretch become extremely hard and fragile. This allows the grinding mill to shatter them cleanly and efficiently, like glass.

The Role of Cryogenic Agents

The process relies on the direct application of a cryogenic agent. Liquid nitrogen (LN2) or liquid carbon dioxide (CO2) are the most common choices.

These agents are injected into the grinding system, often using equipment like paddle screw coolers, to thoroughly chill the material before and during the milling process.

Preserving Product Integrity

By keeping the material well below its glass transition temperature, the process generates virtually no heat damage.

This ensures that volatile aromas, essential oils, and the chemical structure of sensitive compounds remain intact, preserving the final product's quality and efficacy.

Increasing Grinding Efficiency

Brittle materials fracture with far less energy than ductile ones. This results in higher throughput and the ability to achieve finer, more uniform particle sizes.

Furthermore, because the material is frozen and hard, issues with smearing and melting are eliminated, leading to cleaner equipment and more consistent operation.

Understanding the Trade-offs and Considerations

While powerful, cryogenic grinding is a specialized technique with specific costs and requirements that must be weighed.

Higher Operational Costs

The primary trade-off is cost. The continuous supply of liquid nitrogen or carbon dioxide represents a significant operational expense compared to ambient grinding.

Specialized equipment designed to handle cryogenic temperatures and safely introduce the cooling agent is also required.

Material Suitability

Cool grinding is not a universal solution. It provides the most significant benefit for materials that are heat-sensitive, elastic, tough, or oily.

For hard, brittle materials that grind easily at room temperature (like minerals or ceramics), the added complexity and cost are generally not justified.

Safety and Handling

Working with cryogenic liquids requires strict safety protocols. Proper ventilation, personal protective equipment (PPE), and training are essential to prevent cold burns, asphyxiation risks, and over-pressurization of equipment.

When is Cool Grinding the Right Choice?

Choosing this technology depends entirely on your material and your final product goals.

- If your primary focus is preserving quality: For spices, nutraceuticals, or pharmaceuticals, cool grinding is often the only way to protect volatile and heat-sensitive compounds.

- If your primary focus is processing difficult materials: For elastomers, tough plastics, and high-fat products, cryogenic embrittlement makes efficient size reduction possible.

- If your primary focus is achieving ultra-fine particles: The brittle nature of cryogenically frozen material allows for more effective fracturing, resulting in a finer and more consistent final powder.

Ultimately, cool grinding is a precise tool for solving complex material processing challenges that standard methods cannot address.

Summary Table:

| Aspect | Traditional Grinding | Cool Grinding |

|---|---|---|

| Heat Generation | High, causes degradation | Minimal, preserves quality |

| Material Suitability | Hard, brittle materials | Heat-sensitive, elastic, oily materials |

| Particle Consistency | Inconsistent, may smear | Fine, uniform particles |

| Operational Cost | Lower | Higher (due to cryogenic agents) |

Struggling to grind heat-sensitive or tough materials efficiently? KINTEK specializes in advanced lab equipment and consumables, including cryogenic grinding solutions. Our technology ensures your spices, pharmaceuticals, or polymers are milled with precision, preserving vital compounds and boosting your lab's productivity. Contact us today to find the perfect cool grinding system for your needs!

Visual Guide

Related Products

- High Performance Laboratory Freeze Dryer for Research and Development

- High Performance Laboratory Freeze Dryer

- Custom PTFE Teflon Parts Manufacturer Grinding Bowl

- Assemble Square Lab Press Mold for Laboratory Applications

- Lab-Scale Vacuum Induction Melting Furnace

People Also Ask

- What process advantages are offered by integrating a cryogenic cooling device during HPT? Achieve Ultimate Grain Refinement

- What is the process of cryo milling? Achieve Nanoscale Powder & Superior Material Properties

- What is the specific utility of cryomilling for Cantor alloys? Unlock High-Strength Nanocrystalline Structures

- What is the cryomilling technique? Achieve Nanoscale Powders with Superior Purity

- What is a cryo mill? Grind Tough, Heat-Sensitive Samples with Cryogenic Power

- What is the process of cryogenic milling? Achieve Fine Powders from Tough Materials

- What is the mechanism of a cryogenic grinder? Master Polymer Powder Preparation for Additive Manufacturing

- What is cryogenic grinding process? Achieve Fine Powder from Heat-Sensitive Materials