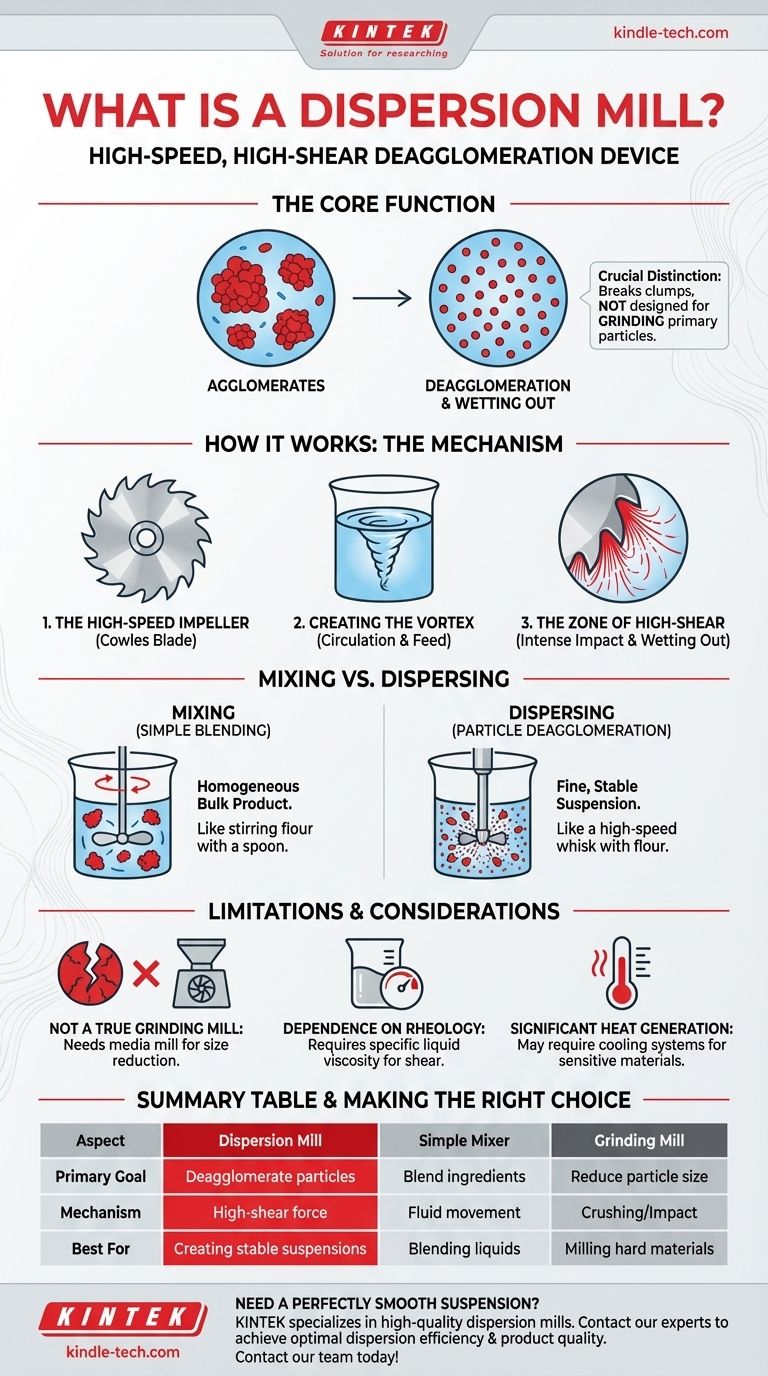

In simple terms, a dispersion mill is a high-speed, high-shear mixing device designed to break apart and distribute solid particles evenly throughout a liquid. Its primary function is not just to stir ingredients, but to apply intense mechanical force to deagglomerate clumps of powder, wet out each individual particle, and create a fine, stable suspension or colloid.

The crucial distinction to understand is that a dispersion mill excels at breaking up agglomerates (particles stuck together) but is not designed for grinding or reducing the size of the primary particles themselves. Its goal is to achieve the smallest possible particle size distribution that the raw material allows.

How a Dispersion Mill Achieves Deagglomeration

The effectiveness of a dispersion mill, often called a high-speed disperser (HSD), comes from the precise fluid dynamics it creates. The process is a function of the impeller design and the speed at which it operates.

The High-Speed Impeller

At the heart of the machine is a specialized impeller, most commonly a flat, circular disc with sawtooth-like teeth around its perimeter. This design, often called a Cowles blade, is engineered to generate immense shear forces at the blade tips.

Creating the Vortex

When the impeller spins at high speeds (typically thousands of feet per minute at the tip), it creates a powerful vortex that pulls material from the surface of the batch down towards the blade. This circulation ensures all material is repeatedly passed through the zone of highest intensity.

The Zone of High-Shear

The real work happens in the small region at the edge of the impeller. As the teeth of the blade impact the slurry, they create a zone of intense turbulence and shear. This force overcomes the bonds holding particle agglomerates together, ripping them apart into their smaller, constituent particles. The liquid is then forced into the newly created surfaces, a process known as "wetting out."

Mixing vs. Dispersing: A Critical Distinction

Many operational failures stem from a misunderstanding between simple mixing and true dispersion. While related, they are fundamentally different processes with different goals and equipment requirements.

Mixing: Simple Blending

Mixing aims to create a homogenous bulk product. It involves moving materials around a tank until they are evenly distributed. A simple propeller agitator can effectively mix two liquids or keep large solids from settling.

Dispersing: Particle Deagglomeration

Dispersion is a more violent, energy-intensive process. Its goal is to break down particle clusters and stabilize them in the liquid phase to prevent them from re-agglomerating.

An Analogy: Flour in Water

Imagine adding flour to water. A simple spoon (a mixer) will stir the water and move the clumps of flour around, but many clumps will remain. A dispersion mill acts like an incredibly high-speed whisk, tearing those clumps apart until only individual flour particles are suspended in the water, creating a smooth paste.

Understanding the Trade-offs and Limitations

While powerful, a dispersion mill is not a universal solution. Understanding its limitations is critical for proper application.

Not a True Grinding Mill

A disperser is highly effective at breaking up agglomerates held together by weak physical forces. However, it lacks the energy to fracture primary crystals or reduce the actual size of the individual particles. For that task, you need a media mill (like a bead or ball mill) that uses grinding media to physically crush the particles.

Dependence on Rheology

The dispersion process relies on the liquid's resistance to flow (its viscosity) to generate shear. If the liquid is too thin, the blade will simply slice through it without creating the necessary force to deagglomerate the solids. Formulations often require a specific viscosity to disperse effectively.

Significant Heat Generation

The immense energy applied during dispersion generates a significant amount of heat. This can be detrimental to heat-sensitive materials, potentially causing degradation, unwanted chemical reactions, or solvent loss. Many dispersion systems require jacketed tanks with cooling systems to manage this temperature rise.

Making the Right Choice for Your Goal

Selecting the correct equipment hinges entirely on the final properties your product requires.

- If your primary focus is blending liquids or suspending non-clumping solids: A simple, low-shear agitator or mixer is often sufficient, more energy-efficient, and easier to operate.

- If your primary focus is creating a fine, stable suspension from powders that tend to clump (e.g., pigments, fillers, thickeners): A high-speed dispersion mill is the correct tool for deagglomeration.

- If your primary focus is reducing the fundamental size of the solid particles themselves: You must use a grinding device, such as a media mill, ball mill, or jet mill, as a disperser will not achieve this goal.

Ultimately, understanding the distinction between simple mixing, particle dispersion, and particle grinding is the key to selecting the right process for a successful formulation.

Summary Table:

| Aspect | Dispersion Mill | Simple Mixer | Grinding Mill |

|---|---|---|---|

| Primary Goal | Deagglomerate particles | Blend ingredients | Reduce particle size |

| Mechanism | High-shear force | Fluid movement | Crushing/Impact |

| Best For | Creating stable suspensions (pigments, fillers) | Blending liquids | Milling hard materials |

| Particle Size | Breaks clumps, not primary particles | No size reduction | Reduces primary particle size |

Need to create a perfectly smooth, stable suspension? KINTEK specializes in high-quality lab equipment, including dispersion mills ideal for deagglomerating pigments, fillers, and other powders in your formulations. Our experts can help you select the right high-shear mixer to achieve optimal dispersion efficiency and product quality. Contact our team today to discuss your laboratory's specific mixing and dispersion challenges!

Visual Guide

Related Products

- Laboratory Single Horizontal Jar Mill

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- What is the use of a colloidal mill? Achieve Perfect Emulsions and Fine Dispersions

- What is the primary function of a laboratory ball mill in copper ore grinding? Optimize Mineral Liberation Efficiency

- What size balls are used in ball milling? Optimize Grinding for Coarse or Fine Powders

- What is the particle size range of a ball mill? Achieve Precise Grinding from 10 mm to Sub-Micron

- What is the mechanism by which high-energy homogenizers improve polymer nanocomposites? Achieve Molecular Dispersion

- How does high-energy dispersion equipment contribute to TiO2 composite electrolyte slurries? Optimize Ion Transport

- Why is grinding equipment used for sulfur-carbon solid-state battery cathodes? Achieve Peak Conductivity

- Why is a rod mill preferred over a ball mill for the grinding stage in magnesite flotation tests? Minimize Fine Dust.