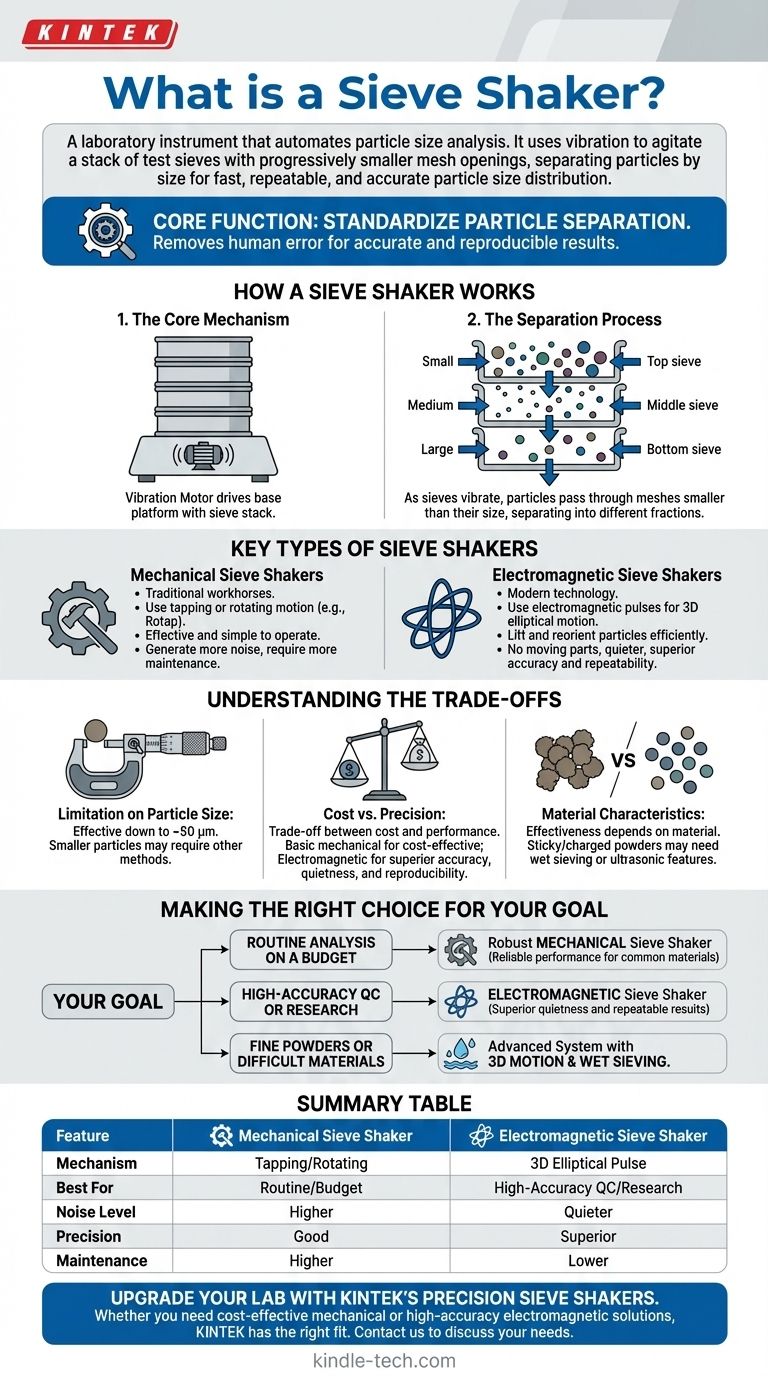

In short, a sieve shaker is a laboratory instrument that automates the process of particle size analysis. It uses a vibration source to agitate a stack of test sieves with progressively smaller mesh openings, causing particles to separate by size. This replaces inconsistent manual hand sieving with a fast, repeatable, and accurate method for determining the particle size distribution of a granular material.

The core function of a sieve shaker is to standardize particle separation. By providing a consistent and controlled motion, it removes human error and ensures that particle size analysis results are both accurate and reproducible over time.

How a Sieve Shaker Works

The Core Mechanism

A vibration motor serves as the heart of the sieve shaker. This motor drives a base platform where a stack of test sieves is securely mounted.

When activated, the motor causes the entire sieve stack to vibrate in a specific, controlled motion.

The Separation Process

As the sieves vibrate, the material sample on the top sieve is agitated. Particles smaller than the mesh openings of a given sieve pass through to the next one below.

This process continues down the stack, with each sieve capturing particles larger than its own mesh but smaller than the mesh of the sieve above it. The result is a precise separation of the material into different size fractions.

Key Types of Sieve Shakers

The particle analysis industry primarily relies on two main types of shakers, distinguished by their mechanism and the type of motion they produce.

Mechanical Sieve Shakers

These are the traditional workhorses of many labs. They often use a tapping or rotating motion (like a "Rotap" shaker) to move particles.

Mechanical shakers are effective and simple to operate, but their moving parts can generate more noise and may require more maintenance over time.

Electromagnetic Sieve Shakers

These modern shakers use electromagnetic pulses to create a three-dimensional elliptical motion. This sophisticated movement efficiently lifts and reorients particles, helping them find an opening in the sieve mesh.

Because they have no moving parts, electromagnetic shakers are significantly quieter and are often recommended for tests requiring the highest levels of accuracy and repeatability.

Understanding the Trade-offs

While highly effective, sieve shakers have operational boundaries and considerations that are important to understand.

Limitation on Particle Size

Sieve shakers are most effective for particles down to about 50 micrometers (µm). For materials with a significant fraction of particles smaller than this, other analysis methods may be necessary to achieve accurate results.

Cost vs. Precision

There is a direct trade-off between cost and performance. A basic mechanical shaker is a cost-effective solution for many applications.

However, an electromagnetic shaker, while more expensive, provides superior accuracy, quieter operation, and greater reproducibility, which can be critical for stringent quality control or research.

Material Characteristics

The effectiveness of sieving depends on the material itself. Sticky, agglomerated, or electrostatically charged powders can be difficult to separate. In these cases, specialized features like wet sieving capabilities or ultrasonic shakers may be required.

Making the Right Choice for Your Goal

Selecting the appropriate sieve shaker depends entirely on your specific analysis requirements.

- If your primary focus is routine analysis on a budget: A robust mechanical sieve shaker provides reliable performance for a wide range of common materials.

- If your primary focus is high-accuracy quality control or research: An electromagnetic sieve shaker is the superior choice for its quiet operation and highly repeatable results.

- If your primary focus is analyzing fine powders or difficult materials: Look for a system that offers advanced features like 3-D motion and options for wet sieving.

Ultimately, choosing the right sieve shaker transforms your particle analysis from a manual task into a controlled and scientific process.

Summary Table:

| Feature | Mechanical Sieve Shaker | Electromagnetic Sieve Shaker |

|---|---|---|

| Mechanism | Tapping or rotating motion | 3D elliptical motion via electromagnetic pulses |

| Best For | Routine analysis on a budget | High-accuracy quality control or research |

| Noise Level | Higher (more moving parts) | Quieter (no moving parts) |

| Precision | Good for common materials | Superior accuracy and repeatability |

| Maintenance | May require more over time | Lower maintenance |

Upgrade your lab's particle analysis with KINTEK's precision sieve shakers.

Whether you need a cost-effective mechanical shaker for routine checks or a high-accuracy electromagnetic system for stringent quality control, KINTEK has the right solution for your laboratory. Our equipment ensures fast, repeatable, and accurate particle size distribution analysis, helping you maintain consistent quality and efficiency.

Contact us today to discuss your specific needs and find the perfect sieve shaker for your application. Get in touch with our experts now!

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Vibratory Sieve Shaker Machine Dry Three-Dimensional Vibrating Sieve

- Laboratory Multifunctional Small Speed-Adjustable Horizontal Mechanical Shaker for Lab

People Also Ask

- How do high-precision sieving systems benefit zeolite preparation? Maximize Adsorption for Wastewater Treatment

- Why is a precision vibratory sieving system important for Pt/Pd alloy analysis? Ensure Data Integrity & XRD Accuracy

- Why is powder classification using standard sieves essential for SHS reactions? Unlock Superior Nitriding Results

- Why is a laboratory sieving system required for bentonite in coatings? Ensure Flawless Surface Performance

- Why is a standardized sieving system necessary for elephant grass research? Ensure Reliable Sample Consistency