At its core, a sputtered low-E coating is a microscopically thin, transparent metallic film applied to glass in a vacuum to dramatically improve its thermal insulation. This high-performance coating is engineered to reflect heat (long-wave infrared energy) back to its source, keeping heat inside during the winter and outside during the summer, all while allowing visible light to pass through. The "sputtering" part refers specifically to the sophisticated manufacturing process used to create it.

The most important thing to understand is that sputtered coatings—also known as "soft coats"—offer the highest level of energy performance available. However, this performance comes with a trade-off: the coating is delicate and must be protected inside a sealed insulated glass unit (IGU).

How Sputtered Coatings Control Heat

To grasp the value of a sputtered coating, you first have to understand the "low-E" principle. "E" stands for emissivity, which is a material's ability to radiate energy. Highly emissive materials radiate heat easily, while low-emissivity materials do not.

### The Principle of Low Emissivity

Standard, uncoated glass has a high emissivity. It absorbs heat and readily radiates it in all directions. This means in winter, your indoor furnace heat is absorbed by the window and radiated outside, and in summer, outdoor heat is radiated inside.

A low-E coating is like a thermal mirror. It has very low emissivity, so it reflects long-wave infrared energy (heat) instead of absorbing and re-radiating it. This dramatically reduces heat transfer through the window.

### Selective Wavelength Filtering

Modern sputtered coatings are spectrally selective. This means they are engineered to differentiate between different wavelengths of the sun's energy.

They allow high levels of visible light (short-wave energy) to pass through, keeping interiors bright. At the same time, they block ultraviolet (UV) light and long-wave infrared (heat) energy, protecting interiors from sun damage and unwanted heat gain.

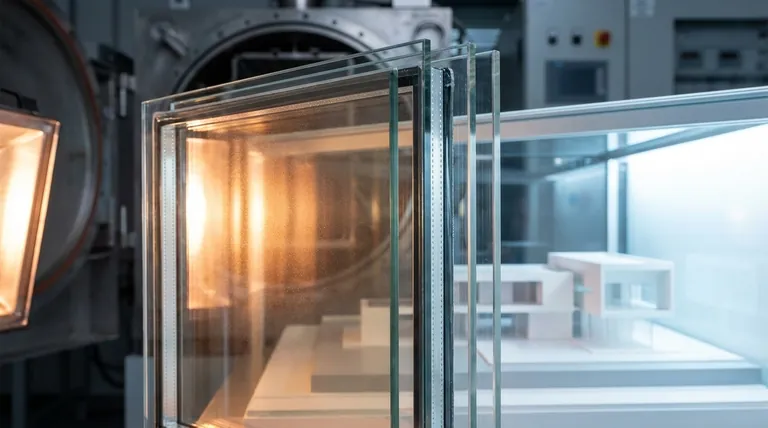

The Sputtering Process Explained

Sputtering is a type of Physical Vapor Deposition (PVD) that takes place in a large vacuum chamber. It is an "offline" process, meaning it is done after the glass has already been manufactured.

### A Microscopic Billiards Game

Think of the process as a microscopic game of atomic billiards. Inside the vacuum chamber, a high-voltage electric field energizes a gas (typically argon), creating a plasma of charged ions.

These ions are accelerated and shot at a "target" made of the desired coating material, most commonly silver. When the ions strike the target, they knock off, or "sputter," individual atoms.

### Building the Coating, Layer by Layer

These sputtered atoms travel across the chamber and deposit onto the cool surface of the glass, forming an exceptionally thin and uniform film.

The true power of sputtering is the ability to create multiple, distinct layers. A typical high-performance sputtered low-E coating might have 5 to 10 layers, including one, two, or even three layers of silver for maximum performance, with other materials acting as protective or anti-reflective layers.

Understanding the Trade-offs: Sputtered vs. Pyrolytic

The alternative to a sputtered "soft coat" is a pyrolytic "hard coat." Understanding the difference is critical for making the right material specification.

### Sputtered "Soft Coat"

Sputtered coatings offer the highest performance. The process allows for multiple layers of silver, resulting in extremely low U-factors (a measure of heat loss) and a wide range of Solar Heat Gain Coefficients (SHGC) to tune the glass for a specific climate.

However, these coatings are delicate. The silver layers will oxidize and degrade if exposed to air or moisture. For this reason, sputtered coatings must be located on a protected surface within a dual-pane or triple-pane Insulated Glass Unit (IGU).

### Pyrolytic "Hard Coat"

Pyrolytic coatings are applied "online" during the glass manufacturing process itself. The coating material is sprayed onto the hot glass ribbon, fusing it to the surface.

This creates an extremely durable and scratch-resistant "hard coat." Its main advantage is that it can be used on single-pane windows or on exposed surfaces.

The downside is performance. A pyrolytic coating is less effective at reflecting heat than a high-end sputtered coating, resulting in a higher (worse) U-factor. It also offers less flexibility in controlling solar heat gain.

Making the Right Choice for Your Goal

Your choice between a sputtered or pyrolytic coating depends entirely on the project's performance requirements and application.

- If your primary focus is maximum energy efficiency: Sputtered low-E is the definitive choice. Its superior insulating properties are essential for high-performance buildings and projects seeking to minimize energy consumption.

- If your primary focus is durability in an exposed application: Pyrolytic low-E is the only option. It is suitable for projects like storm windows or in applications where a single pane of glass is required.

- If you need to fine-tune solar control for a specific climate: Sputtered low-E provides the flexibility to choose a coating that blocks immense solar heat in a hot climate or allows passive solar heat gain in a cold climate.

Ultimately, understanding the manufacturing process empowers you to select the glass technology that precisely meets the energy goals of your project.

Summary Table:

| Feature | Sputtered Low-E (Soft Coat) | Pyrolytic Low-E (Hard Coat) |

|---|---|---|

| Performance | Highest energy efficiency, lowest U-factor | Good, but lower performance than sputtered |

| Durability | Delicate, must be protected inside an IGU | Extremely durable, can be used in single-pane applications |

| Application | Inside sealed insulated glass units (IGUs) | Can be used on exposed surfaces |

| Solar Control | Highly tunable SHGC for specific climates | Less flexibility in solar heat gain control |

Ready to Specify the Right Coating for Your Project?

Understanding the difference between sputtered and pyrolytic low-E coatings is crucial for achieving your building's energy performance goals. The experts at KINTEK can help you navigate these options and select the ideal laboratory-grade materials for your specific climate and application needs.

Contact us today using the form below to discuss your project and discover how our precision lab equipment and consumables can support your development of high-performance glass coatings.

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- Rotating Platinum Disk Electrode for Electrochemical Applications

- High-Purity Titanium Foil and Sheet for Industrial Applications

- Platinum Sheet Electrode for Laboratory and Industrial Applications

- Platinum Auxiliary Electrode for Laboratory Use

People Also Ask

- What is the process of CVD diamond coating? Grow a Superior, Chemically-Bonded Diamond Layer

- Is diamond coating permanent? The Truth About Its Long-Lasting Durability

- How long does diamond coating last? Maximize Lifespan with the Right Coating for Your Application

- How are tools coated with diamond? Achieve Superior Hardness and Low Friction for Your Tools

- What are the three types of coating? A Guide to Architectural, Industrial, and Special Purpose