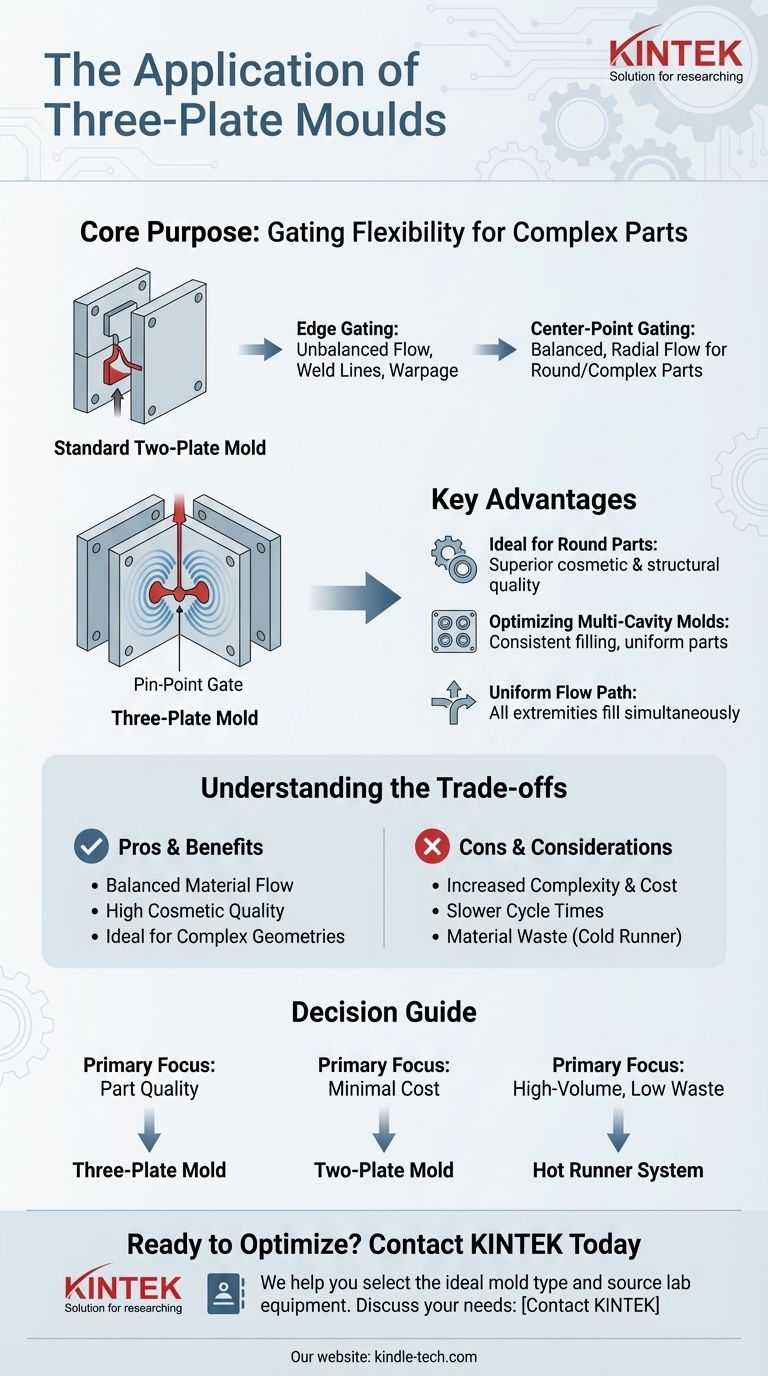

A three-plate mold is primarily used when a plastic part cannot be effectively filled from its outer edges. It is the ideal solution for round parts or complex geometries that require a gate located in the center for balanced material flow and superior cosmetic results.

The central purpose of a three-plate mold is to provide gating flexibility that a standard two-plate mold cannot. It allows you to place a gate directly onto the top surface of a part, away from the parting line, which is critical for achieving optimal part quality in specific designs.

Why a Standard Two-Plate Mold Isn't Always Enough

The Limitation of Edge Gating

The vast majority of injection molds are two-plate designs. They are simple, cost-effective, and reliable.

However, a two-plate mold can only place a gate on the part's parting line—the line where the two halves of the mold separate. This forces material to flow from the edge of the part inward.

For many parts, especially complex or round ones, this edge-flow can cause problems like unbalanced filling, weld lines, and warpage.

The Core Advantage: Center-Point Gating

A three-plate mold introduces a third plate, creating two parting lines. This added complexity serves one primary function: to separate the runner system from the part in a different plane.

Enabling Balanced, Radial Flow

The key benefit is the ability to use a pin-point gate directly on the main surface of the part, typically in the center.

This allows the molten plastic to flow radially outwards from the center, like ripples in a pond. This uniform flow path ensures all extremities of the part fill at the same time and pressure.

Ideal for Round or Symmetrical Parts

This balanced flow is why three-plate molds are perfect for round parts like gears, caps, or lids. Filling from the center eliminates the cosmetic and structural flaws that would occur if you tried to fill them from one side.

Optimizing Multi-Cavity Molds

Three-plate designs also excel in multi-cavity layouts. They can feed multiple parts from their respective centers, ensuring each cavity fills identically and produces consistent parts.

Understanding the Trade-offs

Choosing a three-plate mold is an engineering decision that involves clear trade-offs against a simpler two-plate design.

Increased Mold Complexity and Cost

The addition of a third plate and the associated mechanisms for opening in sequence makes the mold more complex to design, build, and maintain. This complexity translates directly to a higher initial tooling cost.

Potentially Slower Cycle Times

A three-plate mold has a longer opening stroke to eject both the part and the separate runner system. This extra movement can lead to slightly longer cycle times compared to a two-plate mold ejecting a part and runner together.

The Cold Runner System

The runner, which channels plastic to the part, is a "cold runner" in a three-plate mold. This means it solidifies with the part and is ejected as material waste in every cycle, increasing the cost per part.

The Alternative: Hot Runner Systems

For high-volume production, a hot runner system can achieve the same center-gating benefits without the waste.

Eliminating the Runner

A hot runner mold uses a heated manifold system to keep the plastic in a molten state all the way to the gate. Since the runner never solidifies, there is no material waste and cycle times are often faster.

The Cost-Benefit Analysis

Hot runner systems are significantly more expensive and complex than three-plate molds. Therefore, a three-plate mold often represents a strategic middle ground between a simple two-plate mold and a high-performance hot runner system.

Making the Right Choice for Your Part

- If your primary focus is part quality for a round or complex geometry: A three-plate mold is often the most effective choice to ensure balanced filling and avoid cosmetic defects.

- If your primary focus is minimizing initial tooling cost: A standard two-plate mold is the default choice, provided your part design can be successfully gated from the edge.

- If your primary focus is high-volume production with minimal material waste: A hot runner system is the superior long-term solution, despite its high initial investment.

Ultimately, selecting the correct mold type is a critical decision that balances the demands of part quality, production volume, and budget.

Summary Table:

| Feature | Two-Plate Mold | Three-Plate Mold | Hot Runner System |

|---|---|---|---|

| Primary Use | Simple parts, edge gating | Complex/round parts, center gating | High-volume, waste-free production |

| Gating Location | Parting line only | Any surface, including center | Any surface, including center |

| Material Waste | Runner is ejected with part | Runner is separate waste | No runner waste |

| Relative Cost | Low | Medium | High |

| Ideal For | Cost-effective, simple designs | Quality-critical, complex geometries | High-volume, low per-part cost |

Ready to optimize your injection molding process?

Choosing the right mold is critical for the quality and cost-efficiency of your plastic parts. At KINTEK, we specialize in providing the lab equipment and consumables necessary for developing and testing these precise manufacturing solutions.

We can help you:

- Select the ideal mold type for your specific part design and production goals.

- Source equipment for material testing and prototyping.

Let our expertise guide you to a superior outcome. Contact KINTEL today to discuss your laboratory and production needs!

Visual Guide

Related Products

- Polygon Press Mold for Lab

- Special Shape Press Mold for Lab

- Cylindrical Press Mold with Scale for Lab

- Round Bidirectional Press Mold for Lab

- Special Heat Press Mold for Lab Use

People Also Ask

- What is the core function of high-strength graphite molds? Master Vacuum Hot Press Sintering Efficiency

- What are the advantages of using high-strength graphite molds in the hot press sintering of Ti6Al4V-based composites?

- What are the advantages of using PEEK molds for sulfide all-solid-state batteries? High Performance and Insulation

- What is the lifespan of a mold? It's Immortal Unless You Control Moisture

- How do custom graphite molds contribute to Al-20% Si/graphite flake composites? Optimize Microstructure & Conductivity