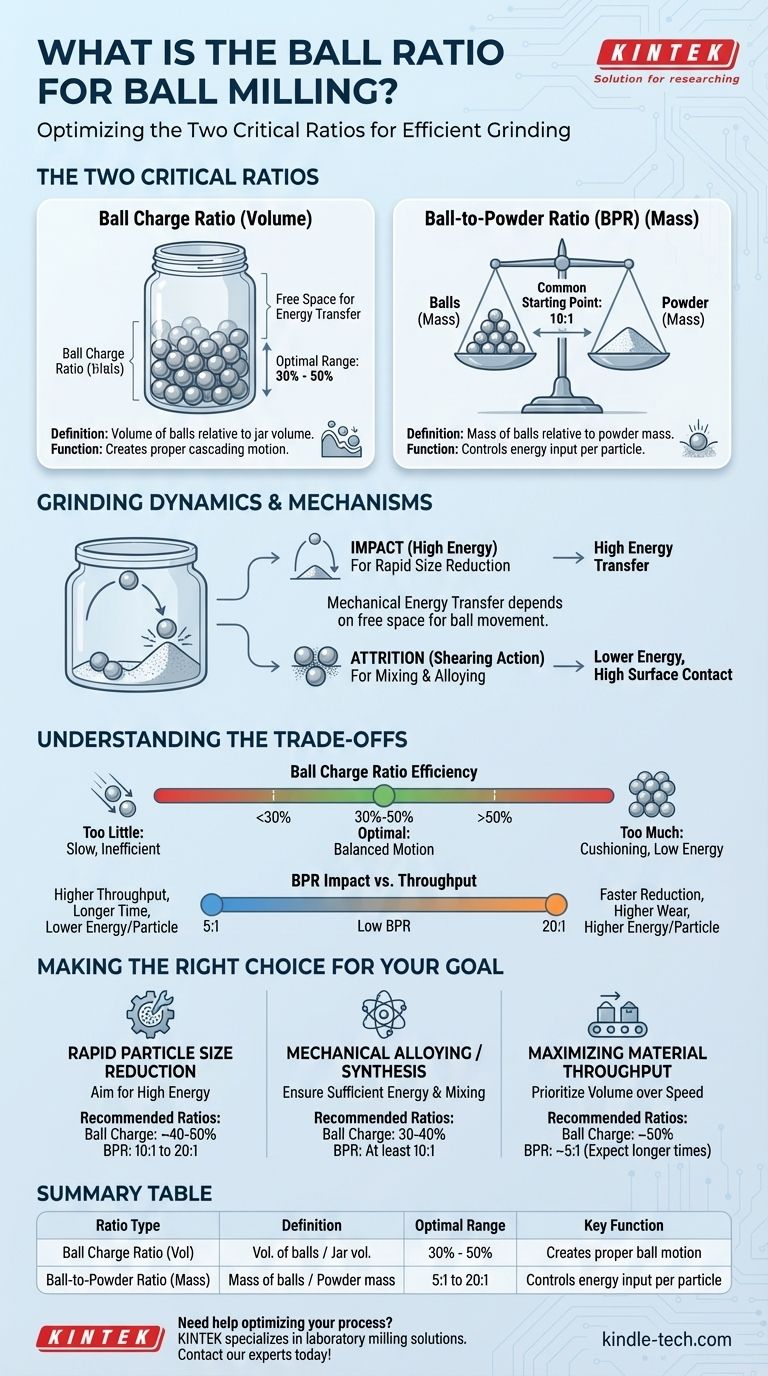

The optimal ball ratio in ball milling is not a single number, but a set of two critical parameters that control the entire process. The first is the ball charge ratio, where the grinding balls should fill between 30% and 50% of the grinding jar's internal volume. The second is the ball-to-powder ratio (BPR), a mass ratio which typically ranges from 5:1 to 20:1, dictating the energy applied to your material.

The core principle is that these ratios are the primary levers for controlling the mechanical energy transferred during milling. The right balance ensures the balls have enough space to move and impact the material with sufficient force, avoiding inefficient grinding or process stagnation.

The Two Critical Ratios in Ball Milling

To optimize your process, you must understand and control two distinct ratios. Each governs a different aspect of the grinding dynamics inside the jar.

Ball Charge Ratio (Volume)

This ratio refers to the volume of the grinding media (the balls) relative to the total internal volume of the milling jar.

The industry standard, supported by practical evidence, is a ball charge between 30% and 50% of the jar's volume. This range is not arbitrary; it is essential for creating the proper "cascading" or "cataracting" motion of the balls.

Ball-to-Powder Ratio (BPR) (Mass)

This ratio compares the total mass of the grinding balls to the mass of the powder or material being milled.

A common starting point for the BPR is 10:1 (10 grams of balls for every 1 gram of powder). This ratio directly influences the grinding efficiency and the amount of energy imparted to each particle during collisions.

How Ratios Dictate Grinding Dynamics

The effectiveness of ball milling comes down to physics—specifically, the transfer of kinetic energy. The ratios you select directly control how this energy is generated and applied.

The Role of Mechanical Energy

Ball milling is a mechanical process where all changes to the material, whether structural or chemical, are induced by mechanical energy. The grinding balls are the medium for transferring this energy from the rotating jar to the powder.

Impact vs. Attrition

The movement of the balls determines the grinding mechanism. Impact occurs when balls fall from the highest point of the jar and strike the powder with high energy. Attrition is the shearing and rubbing action that occurs as balls slide past one another. The right ratios maximize the desired mechanism for your application.

The Importance of Free Space

The empty space in the jar is just as important as the space filled by the balls and powder. This free space allows the balls to be lifted by the jar wall and then fall, converting potential energy into the kinetic energy needed for effective grinding.

Understanding the Trade-offs

Choosing a ratio outside the optimal ranges can drastically reduce efficiency or even halt the grinding process entirely. Understanding these trade-offs is key to troubleshooting and optimization.

The Problem with Too Little Ball Charge (<30%)

A low ball charge results in too few ball-on-particle collisions. Grinding will be extremely slow and inefficient because most of the energy is wasted on the balls simply sliding along the jar's bottom.

The Problem with Too Much Ball Charge (>50%)

Overfilling the jar, often called "cushioning," severely restricts ball movement. The balls lack the necessary space to fall and generate high-impact energy. Instead, they merely tumble over one another, resulting in low-energy attrition that is ineffective for significant particle size reduction.

The Effect of Ball-to-Powder Ratio (BPR)

A high BPR (e.g., 20:1) delivers more energy per particle, leading to faster size reduction. However, this increases the rate of wear and potential contamination from the jar and balls, while reducing the amount of material you can process at once.

A low BPR (e.g., 5:1) allows for higher material throughput per batch. The trade-off is significantly longer milling times, as the energy input per particle is much lower.

Making the Right Choice for Your Goal

Your ideal ratio depends entirely on your desired outcome. Start with a baseline and adjust based on your specific application and results.

- If your primary focus is rapid particle size reduction: Aim for a higher ball charge (around 40-50%) and a high BPR (10:1 to 20:1) to maximize impact energy.

- If your primary focus is mechanical alloying or solid-state synthesis: Use a high BPR (at least 10:1) to ensure sufficient energy for reactions, with a ball charge of 30-40% to promote effective mixing and particle interaction.

- If your primary focus is maximizing material throughput: Use a lower BPR (around 5:1) and fill the jar with a 50% ball charge, but be prepared for significantly longer processing times.

Ultimately, mastering your ball milling process begins with treating these ratios not as fixed rules, but as precise levers to control the final outcome.

Summary Table:

| Ratio Type | Definition | Optimal Range | Key Function |

|---|---|---|---|

| Ball Charge Ratio | Volume of balls relative to jar volume | 30% - 50% | Creates proper ball motion for energy transfer |

| Ball-to-Powder Ratio (BPR) | Mass of balls relative to powder mass | 5:1 to 20:1 | Controls energy input per particle |

Need help optimizing your ball milling process? At KINTEK, we specialize in laboratory equipment and consumables for all your grinding and milling needs. Our experts can help you select the right ratios and equipment to achieve your specific goals—whether it's rapid particle size reduction, mechanical alloying, or maximizing throughput. Contact us today to discuss how we can enhance your lab's efficiency and results!

Visual Guide

Related Products

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Laboratory Single Horizontal Jar Mill

- Laboratory Four-Body Horizontal Jar Mill

- Laboratory Horizontal Planetary Ball Mill Milling Machine

People Also Ask

- What is the primary function of a planetary ball mill for NiCrCoTiV HEA? Optimize Your High-Entropy Alloy Powders

- What is the role of high-energy ball milling in the synthesis of sulfide solid-state electrolytes? Powering Synthesis

- Is a ball mill used for fine grinding? Achieve Micron to Nanometer Particle Sizes

- What is the role of a planetary ball mill in the mechanochemical synthesis of Li3InCl6? Unlock High Ionic Conductivity

- Why Use a Planetary Ball Mill for LLZO/LAGP Fillers? Optimize PEO Composite Electrolytes

- What role does a high-energy planetary ball mill play in the synthesis of magnetic nanocatalysts? Enhance Fenton Reactions

- What physical conditions do high-energy ball mills provide? Optimize Catalyst Synthesis via Mechanical Activation

- What is the function of mechanical ball milling and grinding in biomass pretreatment? Boost Reactivity and Efficiency