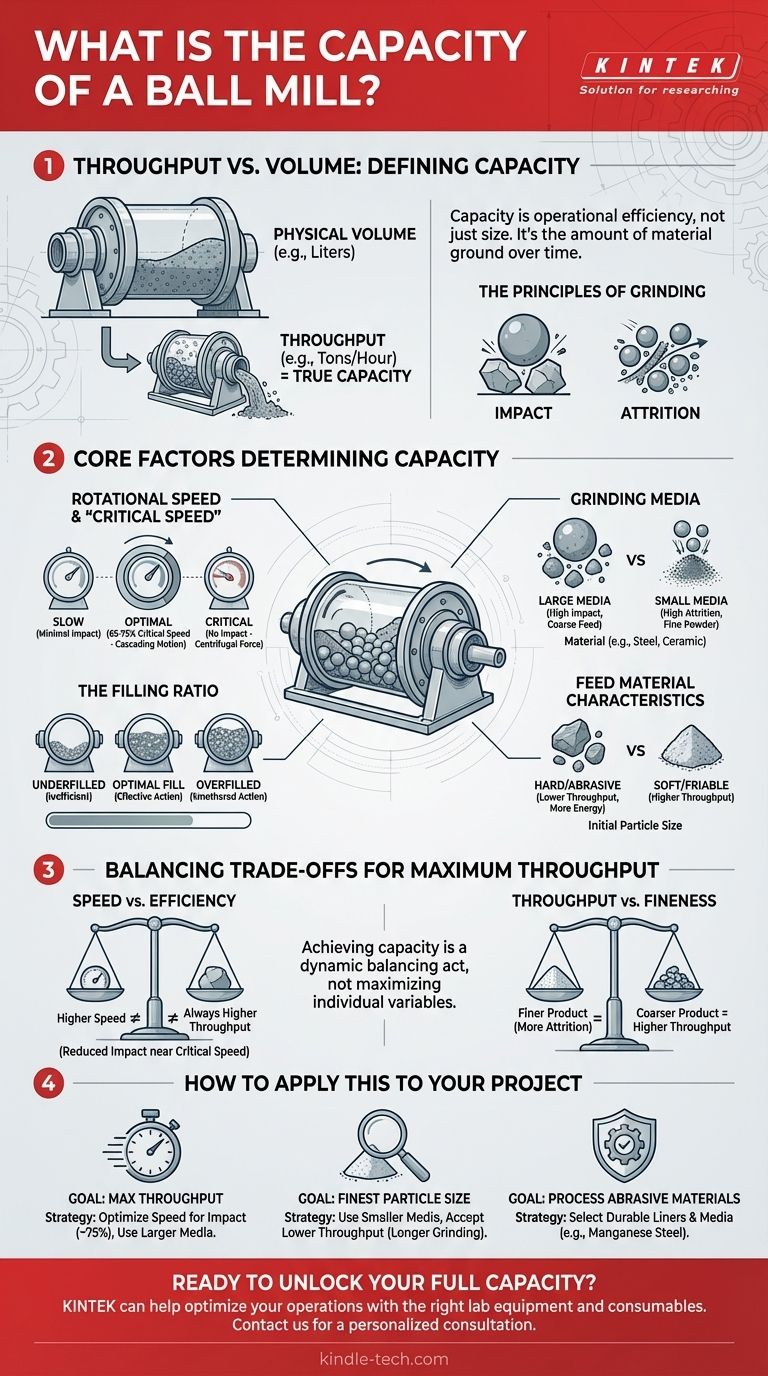

In practice, a ball mill's capacity is not a single, fixed number. Instead, it is the resulting throughput determined by a combination of its physical size and several critical operating parameters. These factors include the mill's rotational speed, the type and size of the grinding media, the characteristics of the material being processed, and the volume of material loaded into the mill.

The "capacity" of a ball mill is less about its physical volume and more about its operational efficiency. To understand a mill's true throughput, you must analyze the dynamic interplay between its speed, grinding media, and the material itself.

What "Capacity" Means for a Ball Mill

Defining Throughput vs. Volume

A ball mill's capacity is best understood as its throughput—the amount of material it can grind to a specified particle size over a period of time (e.g., tons per hour).

This is different from its physical volume. A large mill operated inefficiently will have a lower capacity than a smaller, optimized mill.

The Principles of Grinding

The mill's performance relies on two core principles mentioned in the references: impact and attrition.

Impact is the crushing force from balls falling onto the material. Attrition is the shearing action that occurs as balls and particles rub against each other. The balance between these two forces dictates the grinding efficiency and, therefore, the final capacity.

The Core Factors That Determine Capacity

To determine a ball mill's effective capacity, you must consider how several key variables interact. Each one directly influences the rate and quality of the grinding process.

Rotational Speed and the "Critical Speed"

A mill's rotational speed is arguably the most crucial factor. The references highlight the concept of critical speed, which is the theoretical speed where centrifugal force causes the grinding media to cling to the inner wall of the mill.

Operating too slowly results in minimal impact, as the balls just roll over each other at the bottom. Operating at or above critical speed eliminates impact entirely, stopping the grinding process.

Optimal capacity is typically achieved when the mill runs at 65-75% of its critical speed, creating the perfect cascading motion for both impact and attrition.

The Role of Grinding Media

The grinding media (the balls) are the primary tools for size reduction. Their characteristics are critical to performance.

Media size determines the nature of the force. Larger balls create greater impact, which is effective for breaking down coarse feed material. Smaller balls create more surface area and favor attrition, which is better for producing very fine powders.

Media material (e.g., steel, ceramic) affects the impact force and resistance to wear. Harder, denser media like steel provides more powerful impacts, increasing throughput for tough materials.

Characteristics of the Feed Material

The material being ground has a direct and significant impact on capacity.

Hard, abrasive materials require more energy and time to break down, which naturally lowers the mill's throughput. The initial particle size of the feed also matters; a larger feed size will require more grinding time to reach the desired output fineness.

The Filling Ratio

The filling ratio is the percentage of the mill's internal volume occupied by the grinding media and the material itself.

An optimal fill level ensures there is enough media to grind effectively but also enough empty space for the media to cascade and impact the material. Overfilling the mill smothers this action, drastically reducing efficiency and capacity.

Understanding the Trade-offs for Maximum Throughput

Achieving maximum capacity is not about maximizing each variable individually. It is a balancing act filled with critical trade-offs.

Speed vs. Efficiency

Running a mill faster does not always increase throughput. Pushing the speed too close to the critical limit reduces the effective impact of the falling media, leading to less efficient grinding and potentially lower capacity, even though the mill is spinning faster.

Throughput vs. Fineness

There is a direct trade-off between how much material you can process and how fine the final product is.

Producing an extremely fine powder (e.g., under 10 microns) requires a focus on attrition, which takes more time. This necessarily reduces the overall hourly throughput of the mill. Conversely, if a coarser product is acceptable, capacity can be increased.

Media Load vs. Grinding Space

Increasing the amount of grinding media can increase the number of impact events, but only up to a point. If the mill is too full of media, there is not enough room for the material to be ground or for the media to move effectively, causing efficiency to plummet.

How to Apply This to Your Project

Your operational goal will determine how you balance these factors to achieve the right capacity for your needs.

- If your primary focus is maximum throughput: Prioritize optimizing the mill speed for powerful impact (around 75% of critical speed) and use larger grinding media suitable for breaking down coarse feed quickly.

- If your primary focus is achieving the finest particle size: Use smaller grinding media to maximize surface area and attrition, and be prepared for a lower overall throughput due to longer required grinding times.

- If your primary focus is processing abrasive materials: Select durable lining and grinding media (like manganese steel) to minimize wear and downtime, which preserves the mill's long-term operational capacity.

Ultimately, a ball mill's capacity is a dynamic result of a carefully optimized system, not a static number on a spec sheet.

Summary Table:

| Factor | Impact on Capacity | Optimal Range / Consideration |

|---|---|---|

| Rotational Speed | Dictates grinding motion and impact force. | 65-75% of critical speed for optimal cascading. |

| Grinding Media Size | Larger balls for coarse feed (high throughput); smaller for fine powders (lower throughput). | Match media size to desired product fineness. |

| Feed Material Hardness | Harder, abrasive materials reduce throughput. | Requires more energy and durable media. |

| Filling Ratio | Overfilling smothers grinding action, reducing efficiency. | Balance media and material volume for effective cascading. |

| Target Particle Size | Finer products require longer grinding times, lowering capacity. | Trade-off between throughput and product fineness. |

Ready to unlock the full capacity of your grinding process? The experts at KINTEK can help you optimize your ball mill operations. We specialize in providing the right lab equipment and consumables to meet your specific throughput and fineness goals. Contact our team today for a personalized consultation to enhance your laboratory's efficiency and productivity.

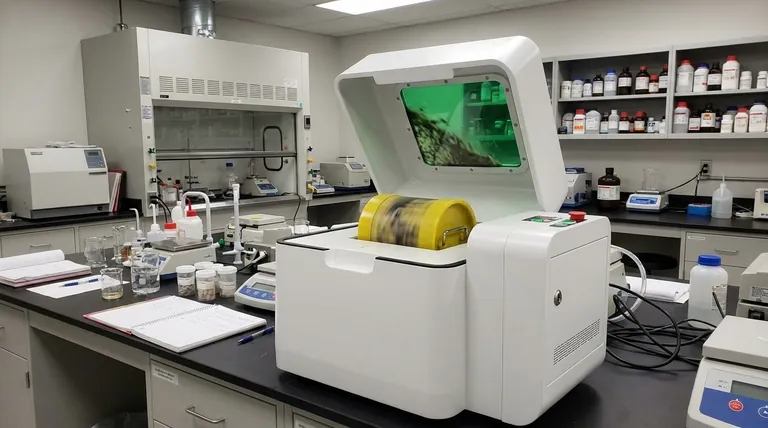

Visual Guide

Related Products

- Laboratory Single Horizontal Jar Mill

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- Why are tungsten carbide grinding jars and balls preferred for high-purity lithium ceramic powders? Ensure Peak Purity.

- Why are zirconia (ZrO2) milling jars recommended for sulfide electrolytes? Ensure Purity in Li6PS5Cl Synthesis

- Why are silicon nitride or zirconia preferred for milling iodo-vanadate-lead precursors? Ensure High Purity Results

- How do stainless steel grinding jars and balls contribute to mechanical alloying? Optimize HEA Powder Synthesis

- Why is a ball mill jar lined with Y-ZrO2 required for Na3PS4 synthesis? Ensuring Purity in Sulfide Electrolytes