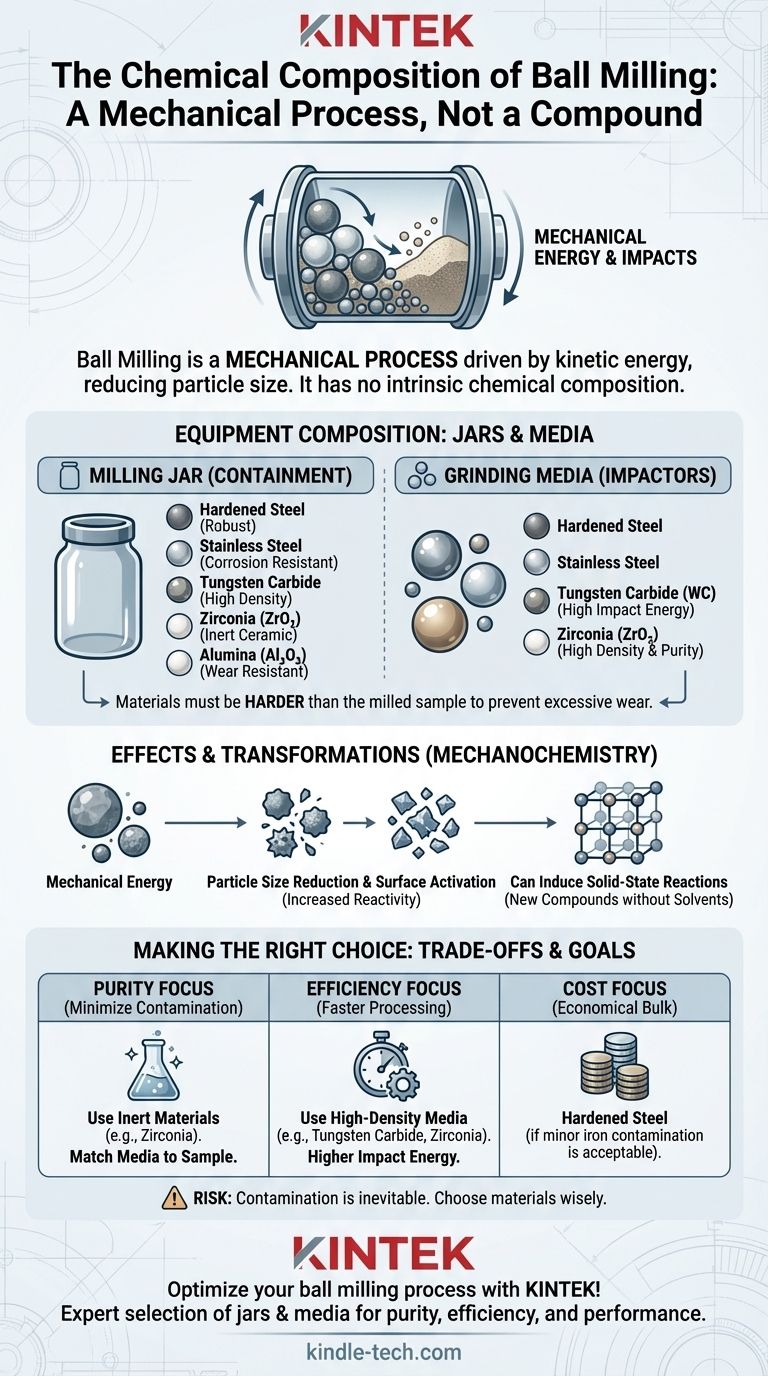

Crucially, ball milling is a mechanical process, not a substance, so it does not have a chemical composition. Instead, the question of chemical composition applies to the equipment used—the milling jar and the grinding balls—as well as the material being processed. These components are typically made from hardened steel, stainless steel, tungsten carbide, or various ceramics like alumina or zirconia to ensure they are harder than the material being milled.

Ball milling is a physical grinding technique that uses mechanical energy to break down materials or induce chemical reactions. The "composition" to consider is that of the milling equipment, as this can directly impact the purity and properties of the final product.

What is Ball Milling Fundamentally?

A Mechanical Process, Not a Chemical Compound

At its core, ball milling is a method for reducing the particle size of solids. It can also be used to blend materials or produce amorphous solids.

The entire process is driven by mechanical energy. A rotating jar causes grinding media (the balls) to tumble and cascade, creating repeated impacts that crush and grind the material trapped between them.

The Key Components: Jars and Grinding Media

A ball mill system consists of two primary parts whose composition is critical:

- The Milling Jar: A container that holds the material and the grinding media.

- The Grinding Media: The balls (or other shapes) that do the actual grinding work through impact and attrition.

The interaction between the balls, the jar wall, and the powder particles is what drives the entire process.

The Chemical Composition of the Equipment

The choice of material for the jar and grinding media is a critical decision based on the application, required purity, and hardness of the material being milled.

Milling Jars: The Containment Vessel

Milling jars are made from robust, wear-resistant materials. The goal is to contain the high-energy impacts without breaking or contaminating the sample.

Common materials include hardened steel, stainless steel, tungsten carbide, and ceramics like zirconia (ZrO₂) or alumina (Al₂O₃).

Grinding Media: The "Balls"

The grinding media must be harder than the material it is intended to grind. To prevent contamination, it is often made of the same material as the jar.

The high density of materials like tungsten carbide (WC) or zirconia provides greater impact energy, leading to more efficient milling compared to lighter media like alumina.

Can Ball Milling Induce Chemical Changes?

While the process is mechanical, the intense energy it generates can absolutely drive structural and chemical transformations in the material. This field is known as mechanochemistry.

Particle Size Reduction and Surface Activation

The most immediate effect of ball milling is the dramatic reduction in particle size, which vastly increases the material's surface area.

This new, highly active surface area can make a material significantly more reactive than its bulk counterpart.

Inducing Solid-State Reactions

The mechanical energy from ball milling can provide the activation energy needed to trigger chemical reactions between solid powders without any solvent.

This is a powerful technique for synthesizing novel alloys, composites, and other compounds directly in the solid state.

Understanding the Trade-offs

Choosing the right milling components involves balancing efficiency, cost, and potential contamination.

The Inevitable Risk of Contamination

No material is infinitely hard. During milling, microscopic amounts of the jar and grinding media will wear away and become incorporated into your sample powder.

Using a steel jar to mill a ceramic powder, for example, will introduce iron contamination. This is why it is common to use a jar and media made of the same material as the sample, if possible, or a material that will not negatively affect the final application.

Process Control Challenges

The energy inside a ball mill is intense and can be difficult to control precisely. Over-milling can lead to unwanted amorphous phases or excessive contamination.

Factors like milling speed, time, ball-to-powder ratio, and temperature must be carefully optimized for reproducible results.

Making the Right Choice for Your Goal

Your choice of milling media composition depends entirely on your end goal.

- If your primary focus is sample purity: Use a jar and media made of a material that will not compromise your sample, such as using a zirconia milling system for a sensitive ceramic material.

- If your primary focus is grinding efficiency: Choose a high-density media like tungsten carbide or zirconia, which delivers higher impact energy for faster processing.

- If your primary focus is cost-effectiveness for bulk materials: Hardened steel is often the most economical choice, provided minor iron contamination is acceptable.

Ultimately, understanding that ball milling is a process empowers you to control its variables to achieve your desired material transformation.

Summary Table:

| Component | Common Materials | Key Properties |

|---|---|---|

| Milling Jar | Hardened Steel, Stainless Steel, Tungsten Carbide, Zirconia (ZrO₂), Alumina (Al₂O₃) | Wear-resistant, chemically inert, contains high-energy impacts |

| Grinding Media | Hardened Steel, Stainless Steel, Tungsten Carbide (WC), Zirconia (ZrO₂) | High density for impact energy, harder than the material being milled |

| Primary Goal | Material Choice Considerations | |

| Sample Purity | Use jar/media of same material as sample or inert ceramics like zirconia | |

| Grinding Efficiency | Opt for high-density media like tungsten carbide or zirconia | |

| Cost-Effectiveness | Hardened steel is economical if minor contamination is acceptable |

Optimize your ball milling process with the right equipment from KINTEK!

Choosing the correct milling jar and grinding media is critical to achieving your desired results, whether your priority is sample purity, grinding efficiency, or cost-effectiveness. Contamination from worn equipment can compromise your entire experiment or production run.

KINTEK specializes in high-quality lab equipment and consumables, including a wide range of ball milling jars and grinding media made from materials like hardened steel, stainless steel, tungsten carbide, zirconia, and alumina. Our experts can help you select the perfect setup for your specific material and application needs, ensuring you get the performance and purity you require.

Don't let equipment choice limit your success. Contact our technical team today for a personalized consultation and ensure your milling process is a success!

Visual Guide

Related Products

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Laboratory Single Horizontal Jar Mill

- Hybrid High Energy Vibratory Ball Mill for Lab Use

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

People Also Ask

- What does the efficiency of a ball mill depend on? Optimize Your Grinding Process for Maximum Performance

- What is the primary function of a planetary ball mill in Li2S cathode prep? Master Nano-Scale Material Synthesis

- What is the primary role of a stirred ball mill in NiAl-Al2O3 preparation? Enhance Your Mechanical Alloying Results

- How does a planetary vacuum ball mill ensure the uniform dispersion of SiC? Master Advanced Nano-Composite Milling

- What are the technical advantages of tungsten carbide grinding jars? Ensure 99.95%+ Purity in Ceramic Milling

- What is the ball mill used for in chemistry? Unlock Solvent-Free Synthesis & Nanomaterial Creation

- What is the primary function of a planetary ball mill for HEA composites? Master Uniform Powder Mixing & Purity

- What role does a high-energy planetary ball mill play in the synthesis of CoCrFeNi(W1-xMox)? Enhance Mechanical Alloying