In short, cryomilling is a specialized grinding technique where materials are milled at extremely low, cryogenic temperatures. This process uses a cryogen like liquid nitrogen to make the material brittle, allowing for the creation of exceptionally fine, nanometer-scale particles while preventing the structural damage that can occur during conventional, room-temperature milling.

The critical insight is that low temperatures fundamentally change the physics of milling. By making materials more brittle and suppressing the tendency for particles to weld back together, cryomilling favors fracturing, enabling the production of purer, smaller, and more uniform nanoparticles than is possible with standard methods.

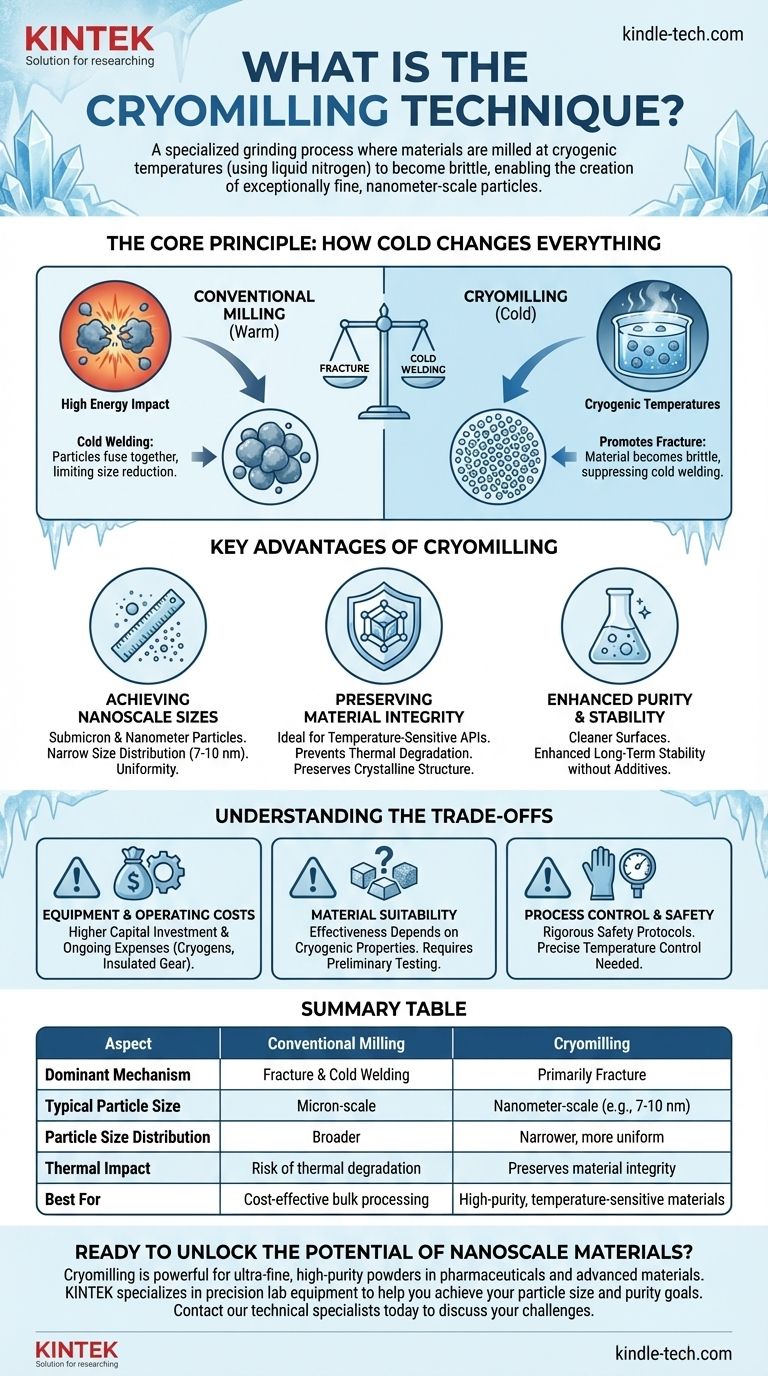

The Core Principle: How Cold Changes Everything

To understand cryomilling, you must first understand the fundamental challenge of conventional milling: the balance between breaking particles apart (fracture) and them sticking back together (cold welding).

The Problem with Conventional Milling: Cold Welding

Mechanical milling is a high-energy process. As particles are repeatedly impacted, the intense localized pressure and energy can cause their surfaces to fuse together.

This phenomenon, known as cold welding, works against the goal of size reduction. It establishes a practical limit on how small and uniform the final particles can be.

The Cryomilling Solution: Promoting Fracture

Cryomilling immerses the material in a cryogen, typically liquid nitrogen, which drops its temperature dramatically. This has two profound effects.

First, it makes most materials significantly more brittle. This means they are far more likely to fracture cleanly upon impact.

Second, the extremely low temperature suppresses the molecular activity that enables cold welding. By tipping the balance heavily in favor of fracture, cryomilling can consistently produce particles that are orders of magnitude smaller and have a much narrower size distribution.

Key Advantages of the Cryomilling Process

This shift from a welding-limited process to a fracture-dominated one provides several distinct advantages that are critical for advanced applications.

Achieving Nanoscale Particle Sizes

The primary benefit is the ability to produce submicron and nanometer-sized particles. This includes nanocrystals for pharmaceuticals and nano-sized grains in metal alloys.

Because fracturing is the dominant mechanism, the process can achieve a very narrow particle size distribution, with some reports showing a range as tight as 7–10 nanometers. This uniformity is crucial for performance and quality control.

Preserving Material Integrity

For temperature-sensitive materials, such as many active pharmaceutical ingredients (APIs), the cryogenic environment is essential.

It prevents thermal degradation and can preserve the original crystalline structure of the material, which is often vital for its function. The liquid nitrogen vaporizes spontaneously after milling, leaving a dry, uncontaminated powder.

Enhanced Purity and Stability

By preventing cold welding, cryomilling produces particles with cleaner surfaces. This can result in nanoparticles that are stable in solution for longer durations, even without the use of surfactants or other stabilizers.

Understanding the Trade-offs

While powerful, cryomilling is a specialized technique with unique operational considerations that make it unsuitable for every application.

Equipment and Operating Costs

The primary trade-off is cost and complexity. Cryomilling requires a supply of cryogenic liquids (like liquid nitrogen or argon) and insulated milling equipment, which increases both the capital investment and ongoing operational expenses compared to conventional milling.

Material Suitability

The effectiveness of cryomilling depends entirely on how a material's properties change at cryogenic temperatures. While it makes most materials more brittle and suitable for fracture, some materials may not respond as expected, requiring careful preliminary testing.

Process Control and Safety

Handling cryogenic liquids demands rigorous safety protocols and specialized training to prevent cold burns and manage pressure build-up from vaporization. The process requires precise control to maintain the desired temperature throughout the milling cycle.

Making the Right Choice for Your Goal

Selecting the right milling technique requires a clear understanding of your project's final objective.

- If your primary focus is achieving the smallest, most uniform particle size: Cryomilling is superior because its suppression of cold welding allows for unparalleled size reduction and consistency.

- If your primary focus is processing temperature-sensitive or volatile materials: The cryogenic environment makes this technique ideal for preserving the material's inherent chemical and physical structure.

- If your primary focus is cost-efficiency for bulk, less-sensitive materials: Conventional mechanical milling is often the more practical and economical choice, as the added benefits of cryomilling may not justify the cost.

Ultimately, cryomilling is a precision tool designed to overcome the physical limits of traditional methods for advanced material production.

Summary Table:

| Aspect | Conventional Milling | Cryomilling |

|---|---|---|

| Dominant Mechanism | Fracture & Cold Welding | Primarily Fracture |

| Typical Particle Size | Micron-scale | Nanometer-scale (e.g., 7-10 nm) |

| Particle Size Distribution | Broader | Narrower, more uniform |

| Thermal Impact | Risk of thermal degradation | Preserves material integrity |

| Best For | Cost-effective bulk processing | High-purity, temperature-sensitive materials |

Ready to unlock the potential of nanoscale materials for your laboratory?

Cryomilling is a powerful solution for producing ultra-fine, high-purity powders essential for advanced research and development in pharmaceuticals, advanced alloys, and nanomaterials. However, selecting and operating the right equipment is critical to achieving your specific particle size and purity goals.

KINTEK specializes in precision lab equipment and consumables, serving the exacting needs of laboratories like yours. Our experts can help you determine if cryomilling is the right technique for your application and provide the reliable equipment you need for consistent, high-quality results.

Contact our technical specialists today to discuss your material processing challenges and discover how KINTEK can support your innovation.

Visual Guide

Related Products

- Laboratory Single Horizontal Jar Mill

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

People Also Ask

- How do stainless steel grinding jars and balls contribute to mechanical alloying? Optimize HEA Powder Synthesis

- Why are excellent sealing and corrosion resistance required for WC-10Co ball milling? Ensure High-Purity Mixing Results

- Why are zirconia (ZrO2) milling jars recommended for sulfide electrolytes? Ensure Purity in Li6PS5Cl Synthesis

- Why are silicon nitride or zirconia preferred for milling iodo-vanadate-lead precursors? Ensure High Purity Results

- What are the advantages of polyurethane ball mill jars for silicon nitride? Ensure Purity & Prevent Metal Contamination