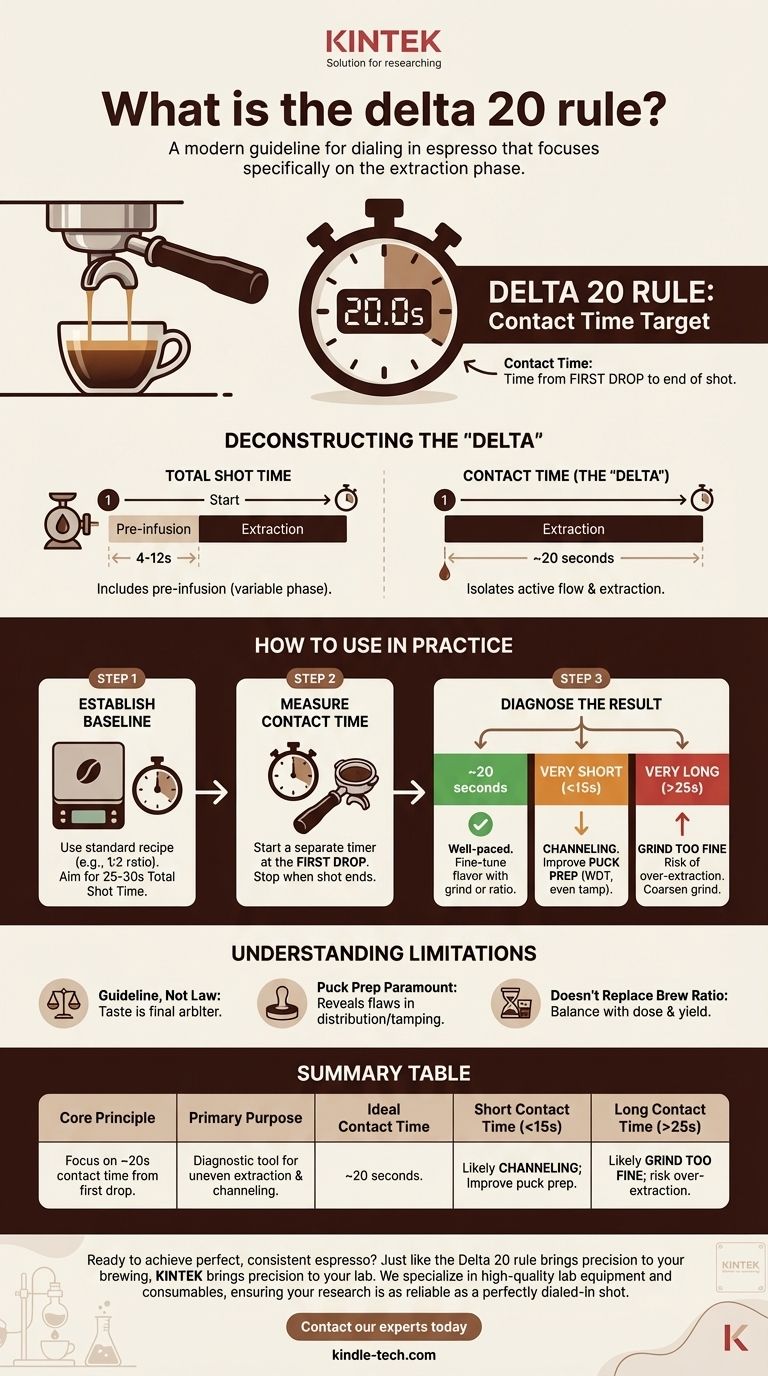

In the world of coffee brewing, the Delta 20 rule is a modern guideline for dialing in espresso that focuses specifically on the extraction phase. It states that the time from the first drop of espresso hitting the cup to the end of the shot should be approximately 20 seconds. This is known as the "contact time," and it is used to diagnose the quality and evenness of the extraction.

The Delta 20 rule isn't a rigid law for flavor, but a powerful diagnostic tool. Its primary purpose is to help you identify and fix issues like channeling by providing a consistent target for the actual extraction time, independent of your machine's pre-infusion phase.

Deconstructing the "Delta"

To properly use this rule, you must understand the difference between the two key timing metrics in an espresso shot.

Total Shot Time vs. Contact Time

Total Shot Time is what most people measure. It starts the moment you engage the pump or lift the lever and ends when you stop the shot. This includes the time it takes for the water to saturate the coffee puck before anything comes out.

Contact Time (the "Delta") begins only when the first drop of espresso appears. This isolates the phase where water is actively flowing through the puck and extracting flavor. The Delta 20 rule focuses exclusively on this period.

Why Isolate Contact Time?

The time it takes for the first drop to appear can vary significantly based on your grinder, coffee beans, and especially your espresso machine's pre-infusion capabilities.

A machine with long, low-pressure pre-infusion might have a 12-second delay, while a basic machine might only have a 4-second delay. By ignoring this variable phase and focusing only on the ~20-second contact time, you get a more consistent and comparable measure of the extraction itself.

How to Use the Delta 20 Rule in Practice

Using this rule is a straightforward process of observation and adjustment.

Establish a Baseline

Start with a standard recipe, such as a 1:2 brew ratio (e.g., 18 grams of coffee in, 36 grams of espresso out). Aim for a conventional total shot time of around 25-30 seconds.

Measure Your Contact Time

While pulling your shot, start a separate timer (or watch the main timer closely) the exact moment the first drop of espresso falls from the portafilter. Stop the timer when you stop the shot. This duration is your "delta."

Diagnose the Result

Now, compare your contact time to the 20-second target.

- If your contact time is ~20 seconds: Your shot is likely well-paced. Now, you can fine-tune the flavor by adjusting your grind size or brew ratio.

- If your contact time is very short (e.g., 12 seconds): This is a classic sign of channeling. Water is rushing through a weak point in the puck instead of flowing evenly. Your primary focus should be on improving puck preparation (using a WDT tool, ensuring an even tamp) rather than just grinding finer.

- If your contact time is very long (e.g., 28 seconds): This suggests your grind is likely too fine, which can "choke" the machine and lead to a bitter, over-extracted shot.

Understanding the Limitations

Like any guideline in coffee, the Delta 20 rule has important context. It is a tool, not a universal law of flavor.

It's a Guideline, Not a Law

Taste is always the final arbiter. Some coffees, particularly very light roasts or those brewed for specific styles like a lungo, may taste better with a longer contact time. Use the rule as a starting point to achieve an even extraction, then deviate based on what tastes best to you.

Puck Prep Is Paramount

The rule is most effective at revealing flaws in your puck preparation. If your contact time is consistently far from the 20-second mark, it is almost always a signal to re-evaluate how you distribute and tamp your coffee grounds.

It Doesn't Replace Brew Ratio

The Delta 20 rule is one of three key variables, alongside your dose (grams of dry coffee) and yield (grams of liquid espresso). A balanced shot requires controlling all three, not just the timing.

Applying the Delta 20 to Your Brewing

Use this rule to move from simply timing shots to intelligently troubleshooting them.

- If your primary focus is consistency: Use the Delta 20 rule as your main diagnostic check to ensure your puck preparation is sound and your extractions are even.

- If your primary focus is dialing in new beans: Aim for the ~20-second contact time as a starting point to find a balanced extraction, then adjust your grind and ratio based on taste.

- If your primary focus is exploring flavor: Once you can consistently hit the 20-second target, treat it as a variable you can consciously change to see how longer or shorter contact times affect the final cup.

Ultimately, the Delta 20 rule empowers you to look past the total shot time and focus on the heart of the process: the quality of the extraction itself.

Summary Table:

| Aspect | Key Takeaway |

|---|---|

| Core Principle | Focus on the ~20-second contact time from the first drop of espresso to the end of the shot. |

| Primary Purpose | A diagnostic tool to identify uneven extraction and channeling, independent of pre-infusion. |

| Ideal Contact Time | Approximately 20 seconds. |

| Short Contact Time (<15s) | Likely indicates channeling; improve puck preparation. |

| Long Contact Time (>25s) | Likely indicates a grind that's too fine, risking over-extraction. |

Ready to achieve perfect, consistent espresso?

Just like the Delta 20 rule brings precision to your brewing, KINTEK brings precision to your lab. We specialize in high-quality lab equipment and consumables, ensuring your research and analysis are as reliable as a perfectly dialed-in shot.

Let us help you perfect your process. Contact our experts today to find the ideal solutions for your laboratory needs.

Visual Guide

Related Products

- 30L Chiller Water Bath Cooling Circulator Low Temperature Constant Temperature Reaction Bath

- Wall Mounted Water Distillation Unit

- Vacuum Cold Trap Direct Cold Trap Chiller

- 20L Chiller Water Bath Cooling Circulator Low Temperature Constant Temperature Reaction Bath

- Vacuum Cold Trap Chiller Indirect Cold Trap Chiller

People Also Ask

- What is the importance of a Recirculating Cooling Water System? Protect Your Lab and Master Reaction Control

- Why is a high-precision chiller core in natural gas hydrate synthesis? Master Thermal Stability for Lab Success

- Why is a circulating water chiller required for Prussian Blue nanoparticles? Ensure Stability & Batch Reproducibility

- For which types of substances are water baths and chillers considered ideal? Essential Care for Sensitive Samples

- Why is a high-performance cooling circulator necessary in silica membrane desalination? Boost Your Permeate Mass Transfer