At its core, a pyrolysis reactor is a specialized vessel designed to thermally decompose material in an oxygen-free environment. The specific design of a reactor is not one-size-fits-all; instead, several distinct types exist, each engineered to control heat transfer and material flow in a way that prioritizes a specific output, such as biochar, bio-oil, or combustible gases.

The choice of a pyrolysis reactor design is fundamentally a decision about how to manage heat. The speed and method of heat transfer dictate the process efficiency and, most importantly, determine the final proportion of solid (biochar), liquid (bio-oil), and gas products.

The Core Principle: Heat Transfer Dictates Product

The primary function of any pyrolysis reactor is to transfer heat to a feedstock (like biomass, plastic, or tires) in the absence of oxygen. The way it accomplishes this is the single most important factor in its design and resulting output.

Slow heating rates favor the production of biochar, as the material has more time to carbonize. Conversely, very rapid heating and quick removal of vapors favor the production of bio-oils and gases. Each reactor design represents a different strategy for achieving a target heating rate.

Common Pyrolysis Reactor Designs

The most common reactor designs are distinguished by how they hold and heat the feedstock.

Batch and Fixed-Bed Reactors: Simplicity and Control

A batch reactor is the simplest form: a sealed container filled with feedstock and heated externally. It's loaded once, run through a full heating cycle, and then emptied.

The fixed-bed reactor is a slight variation where the substrate material is stacked on a stationary bed. Heat is applied, often from the vessel walls, and diffuses inward through the material.

These designs offer excellent energy stability and are relatively simple and inexpensive to build. However, their reliance on slow heat diffusion makes them best suited for slow pyrolysis and maximizing biochar yield.

Fluidized-Bed Reactors: Maximizing Liquid and Gas Yield

A fluidized-bed reactor is engineered for extremely efficient heat transfer. It contains a bed of inert material, such as sand, which is heated.

An inert gas (typically nitrogen) is forced up from the bottom, causing the heated sand and the feedstock particles to behave like a fluid. This "fluidization" ensures that every particle of feedstock is instantly and evenly surrounded by the hot bed material.

This rapid heat transfer makes fluidized-bed reactors ideal for fast pyrolysis, which dramatically increases the yield of valuable byproducts like bio-oils and gases. They are highly effective for uniform, particulate feedstocks like woody biomass.

Auger (Screw) Reactors: Handling Difficult Feedstocks

An auger reactor, also known as a screw reactor, uses a large rotating screw to actively move feedstock through a heated, horizontal chamber.

This design relies on mechanical force to convey material. This makes it exceptionally well-suited for processing heterogeneous or difficult-to-handle materials that might clog other systems.

While robust, the heat transfer is less direct than in a fluidized bed. As a result, auger reactors are typically used for slower processes where the primary desired product is biochar.

Tubular Reactors: A Versatile, Low-Cost Option

A tubular reactor is a simple design, often similar in concept to an auger pyrolyzer. It can be configured to operate based on fixed-bed or fluidized-bed principles.

Its primary advantages are a simple design with relatively low construction and operational costs. While it can be adapted for fast or flash pyrolysis, it is most commonly used for slow pyrolysis applications.

Understanding the Trade-offs

No single reactor design is universally superior. The optimal choice involves balancing competing factors based on your specific goals and constraints.

Heat Transfer Efficiency vs. Mechanical Complexity

Fluidized-bed reactors offer unparalleled heat transfer, but this comes at the cost of higher mechanical complexity and the need for gas handling systems. In contrast, fixed-bed reactors are mechanically simple but have poor heat transfer efficiency, limiting them to slower processes.

Feedstock Flexibility vs. Product Specificity

Auger reactors excel at handling inconsistent, non-uniform feedstocks but are generally optimized for biochar. Fluidized-bed reactors require more uniform, smaller particle sizes but are highly effective at producing bio-oils.

Construction Quality and Safety

Regardless of the design, the quality of construction is critical for safe and reliable operation. High-integrity welds, often verified with X-ray testing, are essential to ensure the sealed vessel can withstand the high temperatures and pressures of pyrolysis without leaks.

Selecting the Right Reactor for Your Goal

Your choice must be driven by your end product, feedstock, and budget.

- If your primary focus is maximizing biochar production: A batch, fixed-bed, or auger reactor is your most direct and cost-effective choice due to their slower heating profiles.

- If your primary focus is maximizing bio-oil and gas yield: A fluidized-bed reactor is the superior option because its rapid heat transfer is essential for this outcome.

- If your primary focus is processing difficult or mixed feedstocks: An auger (screw) reactor provides the necessary mechanical force to handle challenging materials reliably.

- If your primary focus is minimizing initial cost and operational complexity: A simple batch or tubular reactor offers the lowest barrier to entry for slow pyrolysis applications.

Ultimately, understanding these fundamental design trade-offs empowers you to select the reactor that is perfectly aligned with your technical and economic objectives.

Summary Table:

| Reactor Design | Primary Heating Method | Best For Product | Ideal Feedstock |

|---|---|---|---|

| Batch / Fixed-Bed | Slow heat diffusion from walls | Biochar | Various, less sensitive to size |

| Fluidized-Bed | Rapid, uniform heat from inert bed | Bio-oil & Gas | Uniform, small particles (e.g., wood chips) |

| Auger (Screw) | Mechanical conveyance through heated chamber | Biochar | Heterogeneous, difficult materials (e.g., mixed plastics) |

| Tubular | Versatile (can mimic fixed/fluidized) | Biochar (typically) | Cost-sensitive applications |

Ready to Optimize Your Pyrolysis Process?

Choosing the right reactor is critical to achieving your target yields of biochar, bio-oil, or syngas. The experts at KINTEK specialize in designing and supplying robust laboratory-scale pyrolysis systems tailored to your specific feedstock and research goals.

We provide high-quality equipment built for safety and reliability, helping you maximize process efficiency and product quality.

Contact us today to discuss your project requirements and let our team help you select the perfect reactor design. Get in touch via our contact form for a personalized consultation.

Visual Guide

Related Products

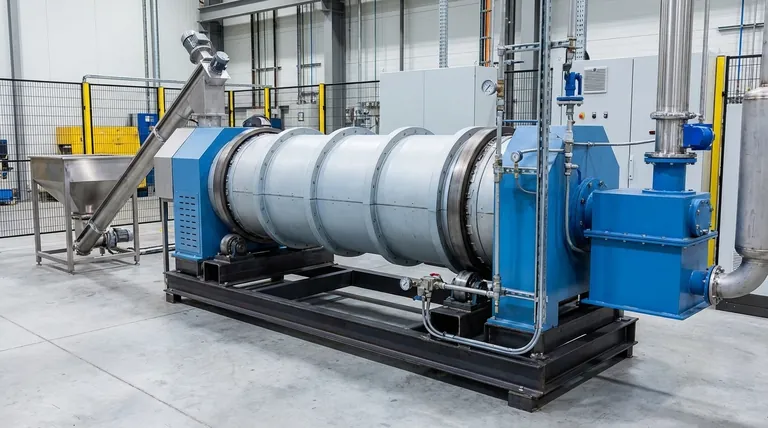

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

People Also Ask

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process

- What are the products of pyrolysis of biomass? Unlock Bio-Char, Bio-Oil, and Syngas

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs

- What are the advantages of pyrolysis technology? Turn Waste into Profit and Reduce Emissions