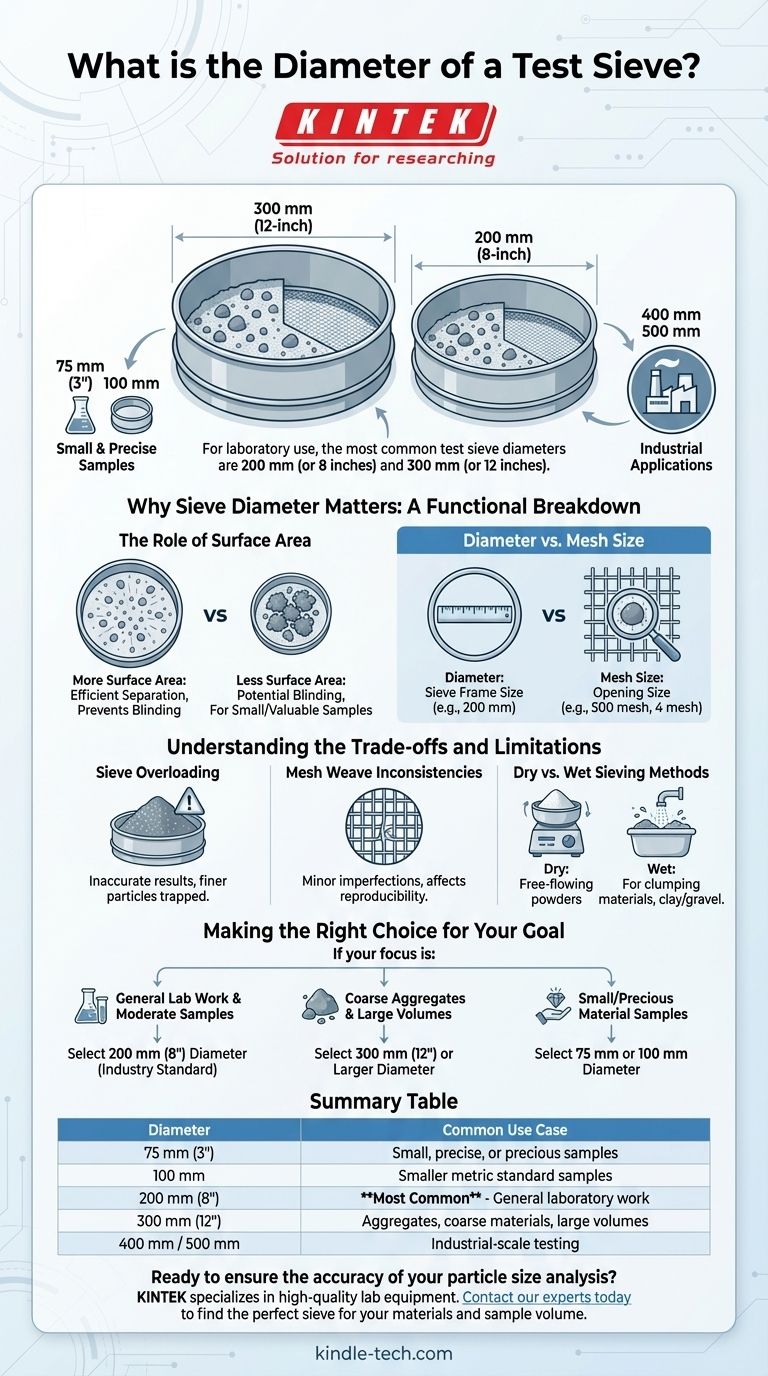

For laboratory use, the most common test sieve diameters are 200 mm (or 8 inches) and 300 mm (or 12 inches). Other standard sizes include 75 mm (3 inches), 100 mm, and larger formats like 400 mm and 500 mm for specific industrial applications.

The diameter of a test sieve is not a single measurement but a range of standard sizes. Selecting the correct diameter is a critical decision based on the volume of your sample material, the size of the particles being analyzed, and the level of accuracy required for your results.

Why Sieve Diameter Matters: A Functional Breakdown

Choosing a sieve involves more than just the mesh opening; the frame's diameter directly impacts the efficiency and validity of your particle size analysis. The diameter determines the available surface area for separation.

The Role of Surface Area

A larger diameter provides more surface area on the sieve mesh. This allows a greater volume of material to be processed at once without blinding the screen, ensuring each particle has an opportunity to pass through the openings.

Smaller diameters are suitable for very small sample sizes or when working with highly valuable material where minimizing loss is critical.

Standard Industry Diameters

While custom sizes can be made, adhering to standard diameters ensures that your equipment is compatible with sieve shakers and that your results are comparable to those from other laboratories.

The most common standard diameters are:

- 75 mm (3 inches): For small, precise samples.

- 100 mm: A smaller-format metric standard.

- 200 mm (8 inches): The most widely used size for general laboratory work.

- 300 mm (12 inches): Common for testing aggregates and larger sample volumes.

- 400 mm & 500 mm: Used for industrial applications with very coarse materials or large-scale testing.

Diameter vs. Mesh Size

It is crucial to distinguish between the sieve's diameter and its mesh size.

- Diameter refers to the size of the sieve frame.

- Mesh size (e.g., 4 mesh or 500 mesh) refers to the size of the openings in the screen, which determines the particle size that is separated.

Understanding the Trade-offs and Limitations

A test sieve is a precision instrument, but its effectiveness is subject to physical and procedural limitations. Understanding these trade-offs is key to generating reliable data.

Sieve Overloading

The most common error in sieve analysis is overloading. Placing too much material on a sieve, especially one with a small diameter, prevents particles from separating correctly. This leads to an inaccurate measurement, as finer particles get trapped above the screen.

Mesh Weave Inconsistencies

Even in certified test sieves, microscopic variations in the weave of the wire mesh can exist. These minor imperfections can slightly affect the reproducibility of test results between different sieves of the same nominal mesh size.

Dry vs. Wet Sieving Methods

The type of material dictates the method. Dry sieving with a mechanical shaker is standard for free-flowing powders. However, for materials with fine particles that clump together or adhere to larger ones (like clay on gravel), a wet wash sieve is required to achieve an accurate separation.

Making the Right Choice for Your Goal

Select your sieve diameter based on the specific requirements of your material and analysis.

- If your primary focus is general lab work with moderate sample sizes: The 200 mm (8-inch) diameter is the versatile industry standard.

- If your primary focus is testing coarse aggregates or processing large volumes: A 300 mm (12-inch) or larger diameter is necessary to ensure a representative sample.

- If your primary focus is analyzing very small or precious material samples: A 75 mm or 100 mm diameter will minimize surface area and reduce material loss.

Ultimately, the right sieve diameter ensures your analysis is not just possible, but accurate and repeatable.

Summary Table:

| Diameter | Common Use Case |

|---|---|

| 75 mm (3") | Small, precise, or precious samples |

| 100 mm | Smaller metric standard samples |

| 200 mm (8") | Most Common - General laboratory work |

| 300 mm (12") | Aggregates, coarse materials, large volumes |

| 400 mm / 500 mm | Industrial-scale testing |

Ready to ensure the accuracy of your particle size analysis?

Choosing the correct test sieve diameter is critical for reliable results. KINTEK specializes in high-quality lab equipment and consumables, offering a full range of standard and custom test sieves to meet your specific laboratory needs.

Contact our experts today to discuss your application and find the perfect sieve for your materials and sample volume. Let us help you achieve precise, repeatable results.

Visual Guide

Related Products

- Laboratory Test Sieves and Vibratory Sieve Shaker Machine

- Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

- Three-dimensional electromagnetic sieving instrument

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- Laboratory Wet Three-Dimensional Vibratory Sieve Shaker Machine

People Also Ask

- What is the role of standard sieves in gold scrap leaching kinetic studies? Ensure Precision in Particle Classification

- Why is it important to clean the sieves before and after testing? Ensure Accurate Particle Analysis

- Can sieving be used to separate a solid substance from a liquid substance? Learn the Right Technique for Your Mixture

- What are the uses of sieves in the laboratory? Master Particle Size for Quality & Performance

- How do you clean test sieves? A Gentle Guide to Preserve Accuracy and Extend Sieve Life

- What is the process of sieve separation? A Guide to Precise Particle Size Analysis

- What role do standard sieves play in the research of graphite flake protection? Quantifying Flake Recovery Rates

- What is the purpose of using a nylon sieve? Optimize MgAl2O4 Powder for Defect-Free Ceramics