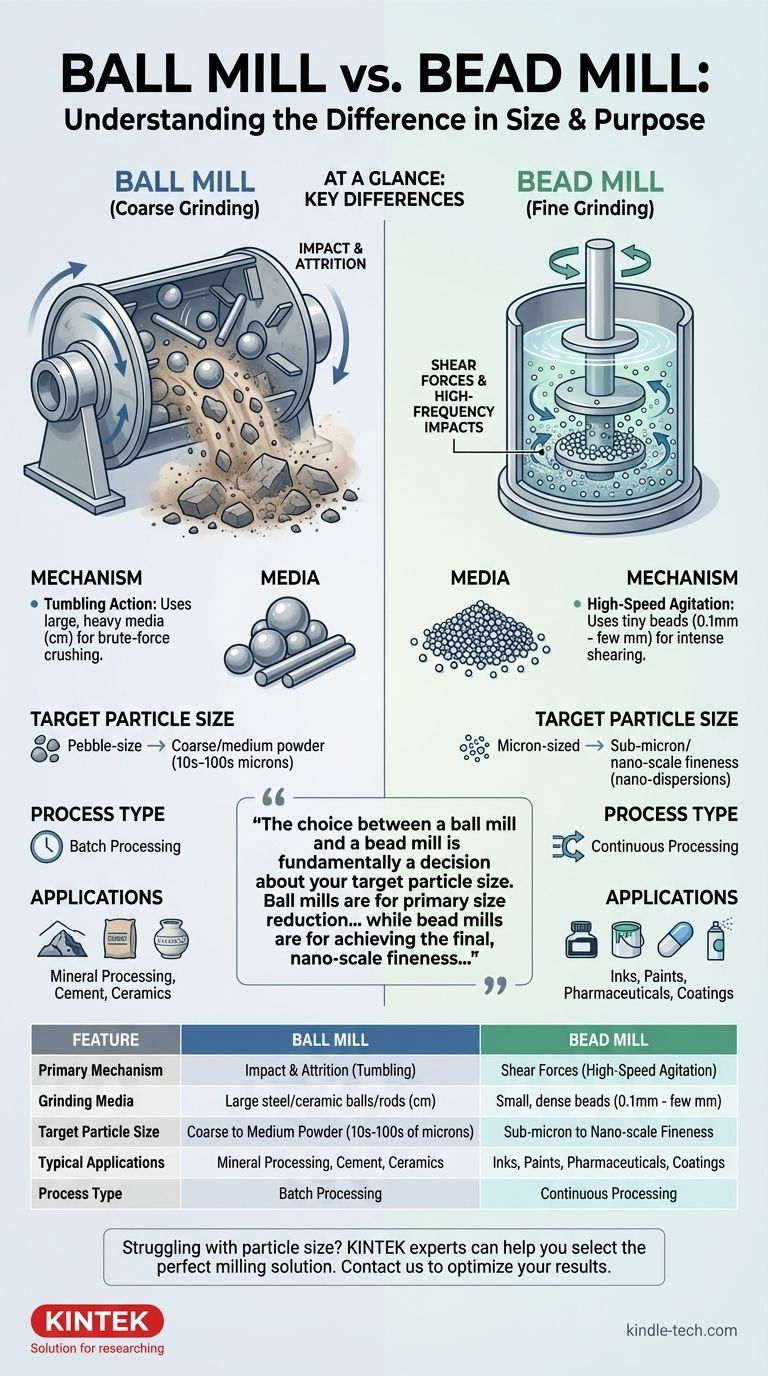

At its core, the difference is size and purpose. A ball mill is a coarse grinding tool that uses large, heavy media like steel balls or rods to break down large, hard materials into powders. A bead mill is a fine grinding tool that uses a high-speed agitator to churn tiny, dense beads, reducing already small particles into ultrafine powders or creating stable liquid dispersions.

The choice between a ball mill and a bead mill is fundamentally a decision about your target particle size. Ball mills are for primary size reduction of raw materials, while bead mills are for achieving the final, nano-scale fineness required in advanced products like inks, pharmaceuticals, and coatings.

Deconstructing the Milling Mechanism

To understand their different applications, you must first understand their fundamentally different methods of applying force.

How a Ball Mill Works

A ball mill is essentially a large hollow cylinder that rotates on its axis. It's partially filled with the material to be ground, along with the grinding media—typically steel balls, ceramic balls, or metal rods.

As the cylinder rotates, the media is lifted up the side and then cascades or cataracts down, crushing and grinding the material through impact and attrition. It is a brute-force method effective for hard, abrasive materials.

How a Bead Mill Works

A bead mill does not tumble. It consists of a stationary grinding chamber filled with tiny grinding beads (e.g., ceramic or glass) and the material to be processed, which is in a liquid slurry form.

A central agitator shaft with discs or pins spins at very high speed. This action violently churns the beads, creating intense shear forces and high-frequency impacts that disperse and de-agglomerate particles down to the sub-micron or nanometer scale.

Key Differentiators at a Glance

While both are mills, they operate in different leagues. The key distinctions lie in the media they use, the particle sizes they produce, and the processes they are suited for.

Grinding Media

A ball mill uses large, heavy media, often several centimeters in diameter. The size and weight are necessary to generate the impact energy needed to fracture large, solid materials.

A bead mill uses media that is significantly smaller and more uniform, typically ranging from 0.1 mm to a few millimeters. The focus is not on raw crushing power but on creating an immense number of contact points for shearing.

Target Particle Size

This is the most critical distinction. A ball mill is used to reduce material from pebble-size down to a coarse or medium powder, typically measured in tens or hundreds of microns.

A bead mill is a finishing tool. It takes a pre-milled slurry and reduces the particle size from the micron level down to the sub-micron or nano-scale, which is essential for product stability and performance in high-tech applications.

Process Type

Ball mills are very well suited for batch processing. You load the mill, run it for a set time, and then unload the finished product.

Bead mills excel at continuous processing. The slurry is continuously pumped through the grinding chamber, allowing for high production efficiency and tight control over the final particle size distribution, as seen in industries like paint and ink manufacturing.

Typical Applications

The applications for each are entirely separate. You will find ball mills used in mineral processing, cement production, and creating ceramic powders—industries where the primary goal is breaking down hard, raw materials.

You will find bead mills in the pharmaceutical, ink, paint, and agrochemical industries. Here, the goal is to create a perfectly stable, fine dispersion of a solid particle within a liquid.

Understanding the Trade-offs

Selecting the wrong technology can lead to inefficiency, product failure, or unnecessary expense.

Energy vs. Fineness

A bead mill is far more energy-intensive per unit of material processed, but it achieves a level of fineness that is physically impossible in a standard ball mill. For coarse grinding, a ball mill is much more energy-efficient.

Contamination and Wear

The high-energy environment inside a bead mill can cause the grinding media itself to wear down, potentially contaminating the product. This necessitates the use of very hard, high-purity ceramic beads, which can be costly.

Upstream Requirements

You cannot simply feed large particles into a bead mill; it requires a pre-milled slurry. This means a bead milling process often requires an upstream milling step (sometimes performed by a different type of mill) to prepare the feed material. A ball mill, by contrast, can often handle much larger starting materials.

Making the Right Choice for Your Goal

Your final decision should be guided entirely by your material's starting state and your desired end product.

- If your primary focus is breaking down raw ore, cement clinker, or other large, hard materials: A ball mill is the correct and most efficient choice.

- If your primary focus is creating a high-performance liquid dispersion like paint, ink, or a pesticide suspension: A bead mill is the industry standard and the only tool for the job.

- If your primary focus is achieving nano-sized particles for advanced pharmaceuticals or coatings: You must use a bead mill to reach the required particle fineness and stability.

By matching the distinct mechanical action of each mill to your specific particle size objective, you can ensure an efficient and effective production process.

Summary Table:

| Feature | Ball Mill | Bead Mill |

|---|---|---|

| Primary Mechanism | Impact & Attrition (Tumbling) | Shear Forces (High-Speed Agitation) |

| Grinding Media | Large steel/ceramic balls/rods (cm) | Small, dense beads (0.1mm - few mm) |

| Target Particle Size | Coarse to Medium Powder (10s-100s of microns) | Sub-micron to Nano-scale Fineness |

| Typical Applications | Mineral Processing, Cement, Ceramics | Inks, Paints, Pharmaceuticals, Coatings |

| Process Type | Batch Processing | Continuous Processing |

Struggling to achieve the right particle size for your product? The choice between a ball mill and a bead mill is critical for your lab's efficiency and final product quality. KINTEK specializes in lab equipment and consumables, serving diverse laboratory needs. Our experts can help you select the perfect milling solution to enhance your process, whether you're crushing raw materials or creating stable nano-dispersions. Contact our team today for a personalized consultation and let us help you optimize your results!

Visual Guide

Related Products

- Stainless Steel Laboratory Ball Mill for Dry Powder and Liquid with Ceramic Polyurethane Lining

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Laboratory Single Horizontal Jar Mill

- High Energy Vibratory Laboratory Ball Mill Double Tank Type

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- What is the function of ball milling equipment in NZSSP electrolyte preparation? Optimize NASICON Solid-State Synthesis

- Why is a laboratory ball mill used in Co-Ni catalyst research? Optimize CO2 Conversion with Precise Milling

- What is the difference between a ball mill and a sag mill? A Guide to Primary vs. Secondary Grinding

- What is the key role of a planetary ball mill for IZO targets? Achieve Atomic-Level Uniformity in Material Preparation

- What is the purpose of ball milling? A Versatile Tool for Material Synthesis and Modification