The fundamental difference between a ball mill and an attritor lies in how they transfer energy to the grinding media. A ball mill relies on gravity, tumbling media inside a large rotating drum to create impact and attrition forces. In contrast, an attritor uses a high-speed rotating internal shaft to actively stir the media in a stationary tank, generating far more intense and efficient shearing forces.

While both machines use grinding media to reduce particle size, the attritor's actively stirred media design makes it significantly faster and more efficient, especially for producing very fine or nano-sized particles. This superior performance, however, introduces different operational trade-offs compared to the simpler, more robust ball mill.

The Mechanics of Grinding: Two Different Philosophies

To choose the right equipment, you must first understand the fundamental mechanics of each system. They achieve the same goal—comminution, or particle size reduction—through distinctly different actions.

How a Ball Mill Works

A ball mill is a cylindrical drum that rotates on a horizontal axis. It is partially filled with the material to be ground, a liquid (if wet grinding), and the grinding media—typically ceramic or metallic balls.

As the drum rotates, the media is lifted up the side of the shell and then tumbles back down. Grinding occurs through two primary mechanisms: impact, as the balls fall, and attrition, as they cascade and slide against each other. The process is gravity-dependent and relatively slow.

How an Attritor Works

An attritor, often generically called a stirred media mill, consists of a stationary, jacketed tank. Inside, a central shaft with attached arms rotates at high speeds.

The tank is filled with the material slurry and much smaller grinding media. The rotating arms vigorously agitate this media, creating a powerful vortex and intense shearing action. The grinding is not dependent on gravity but on the direct, high-energy input from the motor, resulting in more frequent and forceful particle-media collisions.

Key Performance Differences

The mechanical differences between these two mills lead to significant variations in performance, which directly impact process time, final product quality, and operational costs.

Grinding Speed and Efficiency

Attritors are dramatically faster than ball mills, often by a factor of 10 to 20 or even more.

Because the energy is transferred directly into the media field instead of being used to rotate a heavy drum, the process is far more efficient. This translates to significantly shorter milling cycles to reach a target particle size.

Final Particle Size

While ball mills are effective for grinding materials into the micron range, attritors excel at producing sub-micron and nano-sized particles.

The high-intensity shearing action in an attritor is exceptionally effective at breaking down agglomerates and reducing particles to nanometer dimensions, a feat that is often impractical or impossible with a conventional ball mill.

Energy Consumption

For a given amount of material processed to the same fineness, an attritor is more energy-efficient.

The energy from the motor is applied directly to agitating the media, with less energy wasted on moving the mass of the mill itself. This results in lower energy costs per batch, a critical factor in production environments.

Understanding the Trade-offs

Choosing an attritor is not an automatic upgrade. Its high-performance nature comes with specific considerations that may make a ball mill a better choice for certain applications.

Heat Generation and Control

The high energy input of an attritor generates considerable heat. This requires a jacketed tank connected to a cooling system to maintain a stable processing temperature, which is critical for heat-sensitive materials. Ball mills generate heat as well, but at a much lower and more manageable rate.

Batch Size and Scalability

Ball mills are undisputed leaders for very large-scale industrial grinding, capable of processing many tons of material in a single batch.

Attritors are typically used for lab-scale research, pilot projects, and small-to-medium production runs. While large continuous-process attritors exist, traditional ball mills often hold the advantage for massive bulk processing.

Media Wear and Contamination

The intense, high-shear environment inside an attritor can cause slightly higher wear rates on the grinding media and the agitator arms compared to a ball mill. This can be a concern for ultra-high-purity applications where minimizing contamination from the grinding equipment is paramount.

Operational Simplicity

A ball mill is a mechanically simple and extremely robust machine with few moving parts beyond the main drive. It is forgiving and requires minimal oversight. An attritor is more complex, with high-speed shafts, seals, and temperature controls that demand more careful operation and maintenance.

Making the Right Choice for Your Goal

Your decision must be driven by your end goal, balancing the need for performance with operational realities.

- If your primary focus is large-scale, cost-effective grinding to the micron range: The ball mill is the robust, proven, and scalable choice for bulk processing.

- If your primary focus is rapid development or producing nano-scale particles: The attritor is the clear winner due to its speed, efficiency, and ability to achieve sub-micron fineness.

- If your primary focus is processing highly abrasive materials: The simple, heavy-duty construction of a ball mill often provides a longer service life and lower maintenance costs.

- If your primary focus is grinding heat-sensitive materials: The attritor offers superior temperature control via its cooling jacket, but the ball mill generates less heat overall.

Ultimately, understanding these core differences in mechanics and performance empowers you to select the tool that best aligns with your specific material processing objectives.

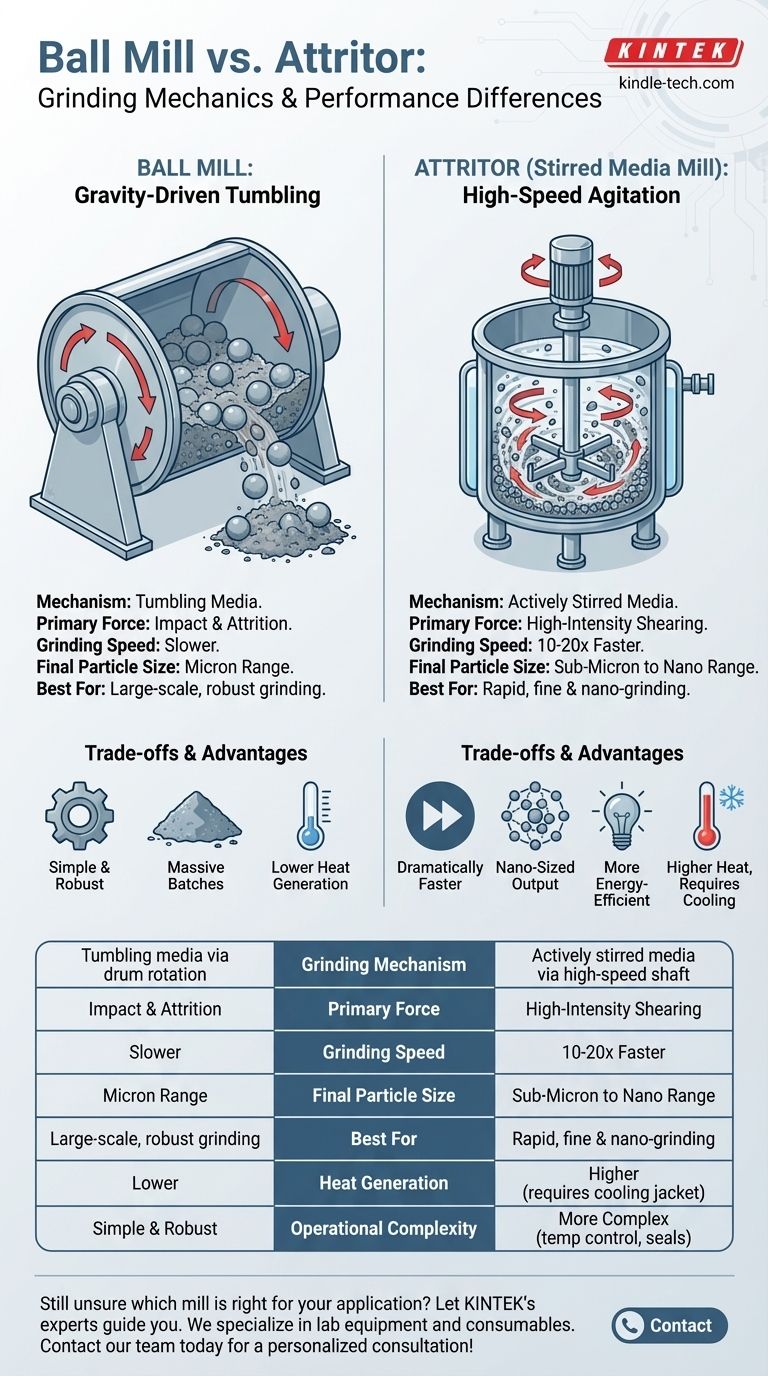

Summary Table:

| Feature | Ball Mill | Attritor (Stirred Media Mill) |

|---|---|---|

| Grinding Mechanism | Tumbling media via drum rotation | Actively stirred media via high-speed shaft |

| Primary Force | Impact & Attrition | High-Intensity Shearing |

| Grinding Speed | Slower | 10-20x Faster |

| Final Particle Size | Micron Range | Sub-Micron to Nano Range |

| Best For | Large-scale, robust grinding | Rapid, fine & nano-grinding |

| Heat Generation | Lower | Higher (requires cooling jacket) |

| Operational Complexity | Simple & Robust | More Complex (temp control, seals) |

Still unsure which mill is right for your application? Let KINTEK's experts guide you. We specialize in lab equipment and consumables, providing solutions for all your laboratory grinding needs. Whether you're scaling up production or developing nano-materials, we can help you select the perfect equipment for optimal efficiency and results. Contact our team today for a personalized consultation!

Visual Guide

Related Products

- Laboratory Planetary Ball Mill Rotating Ball Milling Machine

- High Energy Planetary Ball Mill Machine for Laboratory Horizontal Tank Type

- Laboratory Planetary Ball Mill Cabinet Planetary Ball Milling Machine

- Laboratory Horizontal Planetary Ball Mill Milling Machine

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- What are the effects of ball milling? A Deep Dive into Mechanical Alloying and Material Transformation

- What is the working principle of planetary ball mill? Unlock High-Energy Grinding for Nanoscale Results

- What is the difference between a ball mill and a planetary ball mill? Unlock the Right Grinding Technology for Your Lab

- How does a planetary mill work? Harnessing High-Energy Impact for Nano-Grinding

- What is the function of a planetary ball mill for c-LLZO precursors? Master Solid Electrolyte Prep