At a fundamental level, the difference between a homogenizer and a colloid mill lies in their core mechanism and the result they produce. A homogenizer uses extreme pressure and velocity to force a liquid through a narrow valve, creating exceptionally fine and uniform particle sizes for highly stable emulsions. A colloid mill, in contrast, uses a high-speed rotor and stator to apply intense mechanical shear, which is ideal for creating dispersions and coarser emulsions.

The decision between a homogenizer and a colloid mill is not about choosing a superior technology, but about matching the right tool to your specific goal. Homogenizers excel at creating the finest, most stable emulsions, while colloid mills offer a robust and cost-effective solution for dispersions and less critical emulsions.

Deconstructing the Mechanisms: How They Work

To select the right instrument, you must first understand the physics behind how each one reduces particle size. Their methods are fundamentally different, leading to vastly different outcomes.

The High-Pressure World of the Homogenizer

A high-pressure homogenizer functions like a specialized pump and valve system.

First, a powerful pump pressurizes the liquid product to extreme levels, often between 1,500 and 10,000 PSI or even higher.

This pressurized liquid is then forced at high velocity through a very small, adjustable gap called a homogenizing valve. The immense pressure drop and acceleration cause intense turbulence, cavitation, and shear, which violently tear apart the droplets or particles.

The result is extremely small and uniform particles, often in the sub-micron or nanometer range.

The Mechanical Shear of the Colloid Mill

A colloid mill operates on the principle of high-speed mechanical shearing.

The equipment consists of a fast-spinning rotor that sits within a stationary housing called a stator. The gap between the rotor and stator is extremely narrow and can be precisely adjusted.

As the product is fed into the mill, it is subjected to intense hydraulic shear forces in this tiny gap. Think of it as a deck of cards being smeared; each layer is forced to slide against the next, breaking down particles.

This process is excellent for grinding, dispersing, and emulsifying, but the resulting particle size is typically larger (in the micron range) and less uniform than what a homogenizer can achieve.

Comparing the Outputs: Particle Size and Stability

The difference in mechanism directly dictates the quality and characteristics of the final product. The key metrics are particle size distribution and the long-term stability of the mixture.

The Goal of Homogenization: Uniformity and Stability

Homogenizers are designed to create products where separation is undesirable. The classic example is milk. Homogenization shatters the large fat globules into tiny droplets that are so small and uniform they remain suspended indefinitely, preventing a cream layer from forming.

This extremely fine particle size distribution leads to superior emulsion stability, improved texture, and longer shelf life.

The Goal of a Colloid Mill: Effective Dispersion

Colloid mills are workhorses for creating dispersions and less-critical emulsions. Think of making peanut butter or paint. The goal is to break down solid particles (peanuts, pigments) and thoroughly wet them into a liquid base.

While this creates a smooth product, the particle size is larger and the distribution is wider. Over time, these emulsions may show some separation, which is often acceptable for their intended application.

Understanding the Trade-offs and Limitations

Choosing between these tools involves a clear set of engineering and economic trade-offs. An objective assessment is critical for process design.

Cost and Energy Consumption

High-pressure homogenizers are complex machines with powerful pumps, making them significantly more expensive to purchase and operate. Their high energy consumption is a direct result of generating extreme pressure.

Colloid mills have a simpler design, resulting in lower initial capital costs and generally lower energy consumption for a given throughput.

Maintenance and Material Constraints

The high-wear parts in a homogenizer, such as the valve, seals, and plungers, require regular and more specialized maintenance. They are also highly sensitive to abrasive particles, which can rapidly damage the valve seat.

Colloid mills are generally more robust and forgiving. Their simpler construction makes them easier to clean and maintain, and they can handle materials with higher viscosity and some abrasives more effectively.

Common Applications: Where Each Tool Shines

The choice becomes clear when you look at established industry applications.

Typical Homogenizer Use Cases

Homogenizers are the standard in industries requiring maximum stability and uniformity, such as dairy (milk, cream), pharmaceuticals (IV emulsions, vaccines), and biotechnology (cell disruption/lysis).

Typical Colloid Mill Use Cases

Colloid mills are widely used in food processing (dressings, sauces, pastes), cosmetics (creams, lotions), and the chemical industry for products like paints, inks, lubricants, and greases.

Making the Right Choice for Your Process

Your final decision should be guided entirely by your product's required characteristics and your operational constraints.

- If your primary focus is creating an extremely stable emulsion with a long shelf life (like milk or pharmaceutical injectables): The high-pressure homogenizer is the correct tool for achieving the necessary sub-micron particle size.

- If your primary focus is dispersing solids into a liquid or creating a coarser emulsion for products like sauces, pastes, or creams: A colloid mill provides an effective and more economical solution.

- If your primary focus is disrupting cells for biotech applications: The intense combination of forces from a homogenizer is necessary for efficient cell lysis.

- If you are working with high-viscosity materials or have a limited budget: The robust and simpler design of a colloid mill is likely the better starting point.

Understanding these core mechanical differences empowers you to select not just a piece of equipment, but the precise process required to achieve your desired product quality and stability.

Summary Table:

| Feature | Homogenizer | Colloid Mill |

|---|---|---|

| Core Mechanism | High pressure & velocity through a narrow valve | High-speed mechanical shear (rotor/stator) |

| Typical Particle Size | Sub-micron to nanometer (finer, more uniform) | Micron range (coarser, less uniform) |

| Primary Goal | Superior emulsion stability, long shelf life | Effective dispersion, grinding, coarser emulsions |

| Ideal For | Dairy, pharmaceuticals, biotechnology (cell lysis) | Food pastes, sauces, cosmetics, paints, chemicals |

| Cost & Maintenance | Higher initial cost, specialized maintenance | Lower cost, robust, easier maintenance |

Still Unsure Which Equipment is Right for Your Application?

Choosing between a homogenizer and a colloid mill is critical for achieving your desired product quality, stability, and process efficiency. KINTEK specializes in lab equipment and consumables, serving laboratory needs with expert guidance.

Our team can help you analyze your specific requirements—whether you need the ultra-fine emulsions of a homogenizer or the robust dispersions of a colloid mill—to ensure you invest in the right technology for your success.

Contact us today for a personalized consultation and let KINTEK provide the precise solution your laboratory deserves.

Get Expert Advice & Pricing Now

Related Products

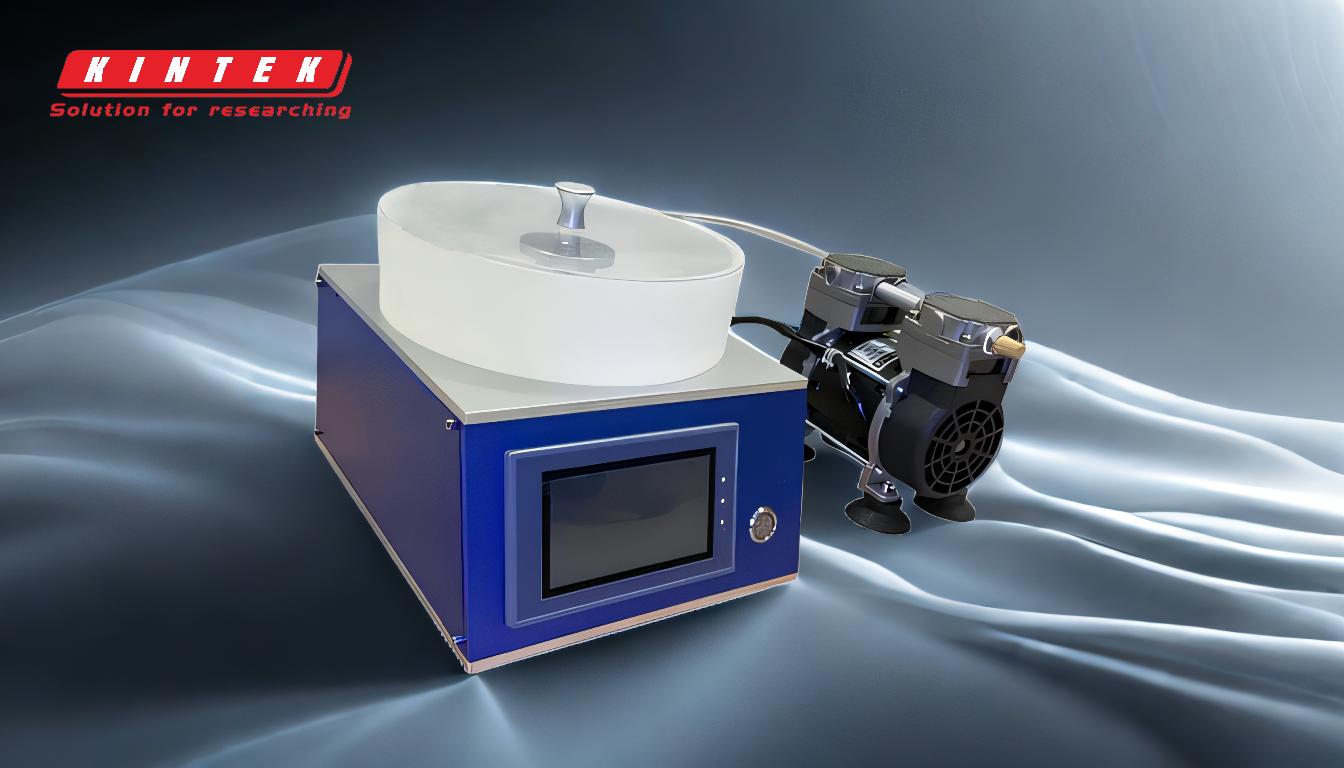

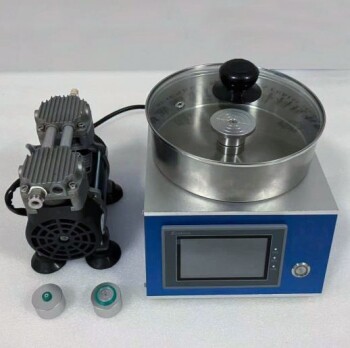

- Laboratory Homogenizer Mixer Benchtop 4 Inch PTFE Cavity Homogenizer

- Laboratory Hybrid Tissue Grinding Mill

- Benchtop Laboratory Homogenizer Mixer with 4 Inch Stainless Steel Chamber for Glue

- Lab Sterile Slapping Type Homogenizer for Tissue Mashing and Dispersing

- Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

People Also Ask

- What are the steps involved in sample preparation? A Guide to Accurate and Reliable Analysis

- What are the 4 methods of determining particle size? Choose the Right Technique for Your Lab

- Why do we need to use properly some of the laboratory apparatus in the laboratory? The Foundation of Safe and Accurate Science

- What is sample grinding? Achieve Accurate Analysis with Proper Sample Preparation

- Why is it necessary to crush or grind the samples? Ensure Accurate & Reliable Lab Analysis